DMK Industrial Metal 3D Printing Services

Description

Demark (DMKLaser) is a one-stop provider of industrial laser processing solutions, specializing in metal 3D printing services with full-stack capabilities across design, manufacturing, and application support.

With a strong foundation in additive manufacturing and intelligent digital production, we operate high-performance GT-series equipment, including multi-laser powder bed fusion systems. Our facility is designed for efficient, high-precision production at scale, serving sectors such as aerospace, medical, automotive, tooling, and electronics.

Founded by Jally and her partners—each with over 20 years of deep expertise in the laser and additive industry—Demark has delivered proven results across demanding applications like aerospace components, orthopedic implants, and conformal cooling molds.

Why Choose DMK Metal 3D Printing Services?

Comprehensive Manufacturing Capabilities

From equipment to execution, we own the full process. We produce both metal 3D printing machines and the printed parts themselves—ensuring superior insight and control.Industry-Proven Team

20+ years of experience in laser and additive manufacturing with real-world success in aerospace, footwear molds, and industrial components.End-to-End Quality Control

Each part is produced with detailed process monitoring: oxygen concentration, chamber pressure, laser paths, and thermal data—ensuring stable performance and full traceability.Wide Material Support

Compatible with stainless steel, titanium alloys, tool steel, cobalt-chrome, aluminum alloys, and high-temperature materials like Inconel.

Application Cases

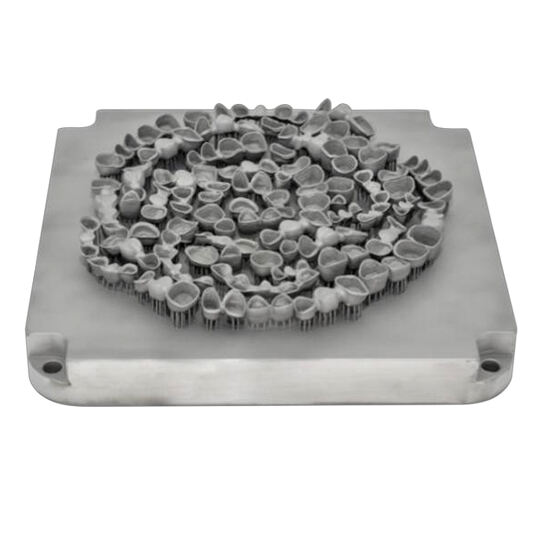

▶ Mold Manufacturing – Conformal Cooling Molds

Used in: Footwear, plastic injection molding

Technology: Internal channel design impossible via CNC

-

Outcome:

Up to 30% reduction in production cycle

Better cooling uniformity

Lower warpage and improved part quality

Reduced long-term production cost

|

Injection mold |

Die casting molds |

|

Shoe molds |

Mold manufacturing |

▶ Medical – Dental and Orthopedic Devices

Products: Custom dental crowns, bridges, orthopedic implants

Highlight: Titanium porous spinal fusion cages with controlled porosity and geometry for better osseointegration

-

Benefits:

Anatomical match and patient-specific customization

Adjustable structure (pore size, porosity, strut thickness)

Lighter weight, better healing outcomes

|

Dental |

Orthopedics |

|

Cervical vertebrae |

Lumbar vertebrae |

▶ Aerospace Components

Advantage: Lightweight structural components with complex geometries

-

Results:

Faster prototyping and iteration cycles

Topology optimization for weight and stress distribution

Increased material efficiency and lifecycle strength

|

Engine |

Fuel nozzles |

|

Aerospace brackets |

Aerospace engines |

▶ Automotive Innovation

Focus: Ergonomic brackets, heat exchangers, and custom exterior parts

-

Outcome:

Functional prototypes and small-batch production

Reduced vehicle weight and improved thermal performance

Enhanced driver comfort and safety

|

Differential |

Engine front covers |

|

Automobile swing arms |

Supercharger volutes |

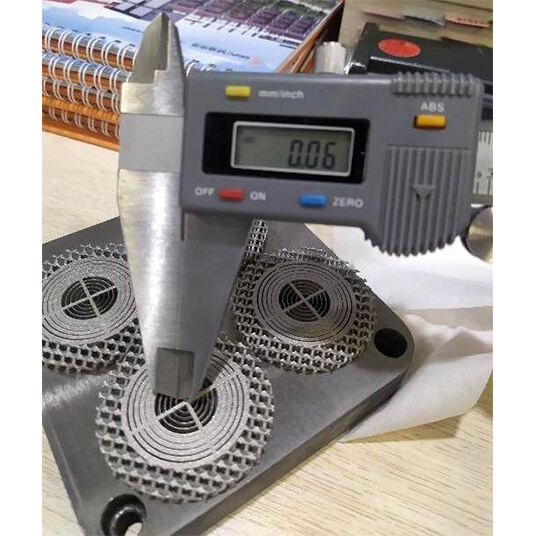

▶ Precision Printing of Fine Structural Components

Using our specially developed GT-series systems with customized laser sources, we deliver high-resolution printing for intricate and topology-optimized parts.

Key Benefits:

Ultra-fine detail resolution for complex geometries

Minimal spatter for smoother surfaces and higher part density

Refined melt pools and microstructure for enhanced mechanical strength

Applications:Scientific research projects

Functional parts requiring lightweight, high-strength features

Aerospace brackets, medical instruments, and heat exchangers

This technology is ideal for labs, universities, and advanced R&D departments where performance and accuracy are paramount.

|

Fine implant structures |

Fine spot 0.08mm thin wall structure |

Supported Materials

Stainless Steel

Tool Steel

Titanium Alloys

Cobalt-Chrome

Aluminum Alloys

High-Temperature Alloys (Inconel, etc.)

About Demark (DMKLaser)

Demark is a leading provider of laser processing systems focused on additive manufacturing and smart digital production. With in-house R&D, manufacturing, and after-sales support, we offer metal 3D printers, resin 3D printers, and laser cleaning machines, serving clients across aerospace, mold, medical, 3C electronics, automotive, and jewelry industries.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR