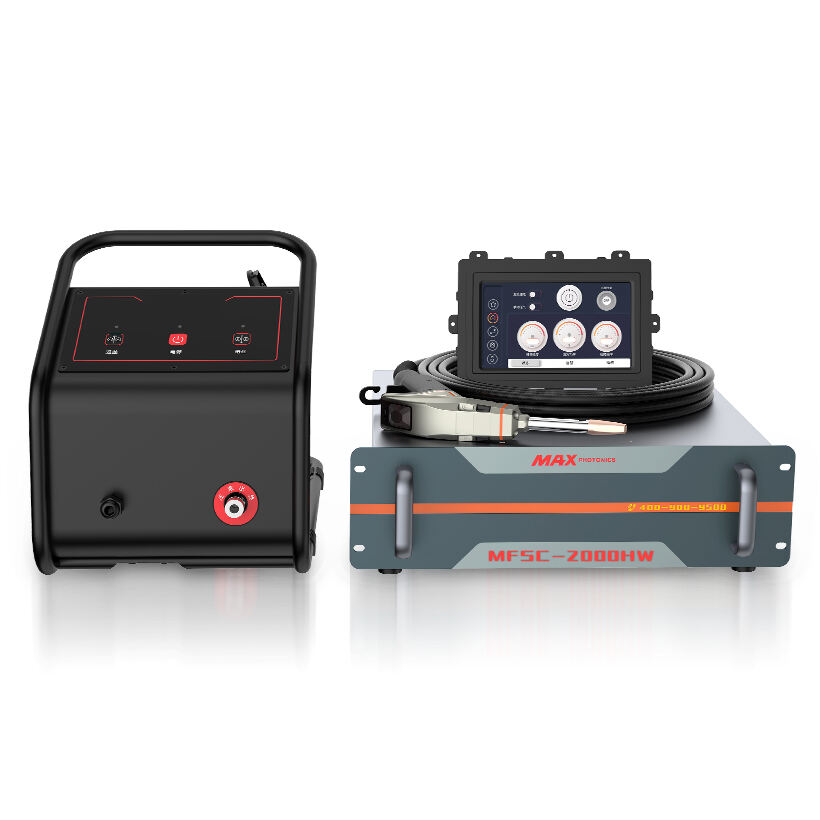

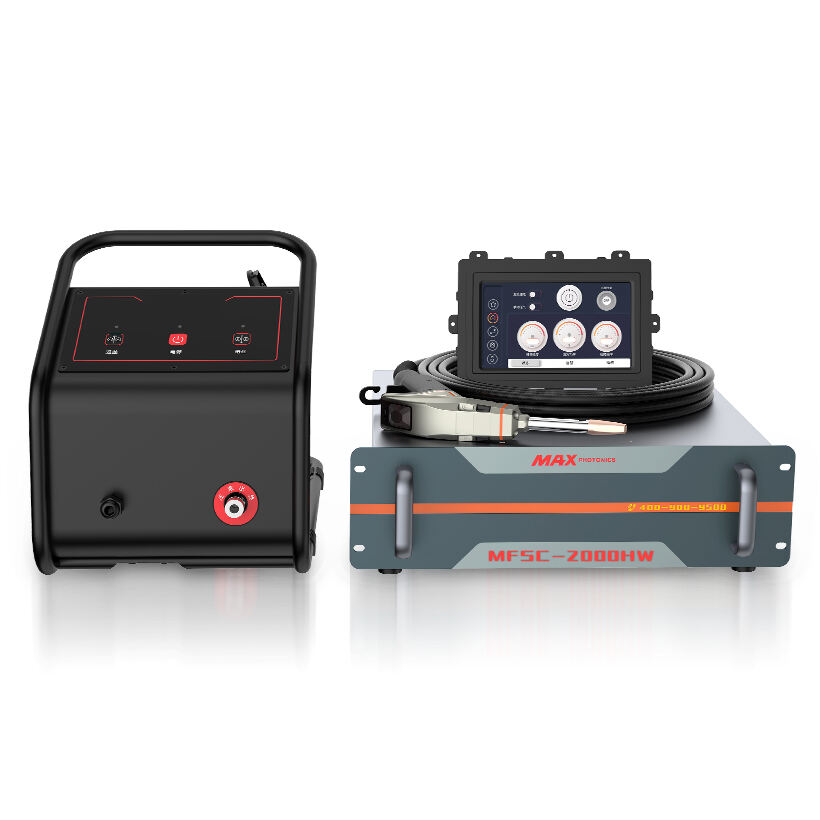

DMK Handheld Laser Welding Source All-in-One Solution

Product Description

Precision, power, and efficiency—brought together in a seamless, all-in-one handheld laser welding solution. The MFSC-1500HW and MFSC-2000HW combine advanced water-cooling technology with exceptional beam quality, delivering high-performance welding for a wide range of industrial applications. Whether used as a standalone handheld device or integrated into robotic systems and CNC platforms, these systems redefine what’s possible in precision laser welding.

Engineered for stability and ease of use, these models feature an integrated laser source, control box, and wire feeder, ensuring a compact and efficient workflow. Designed with durability and user experience in mind, they provide high penetration, clean welds, and effortless operation, making them the ideal choice for industries that demand both reliability and precision.

Key Features

All-in-One Integrated Solution

Combines laser source, control box, and wire feeder in a single, efficient design.

Simplifies installation and operation for enhanced productivity.

Integrated Armored Cable for Reliability

Optical fiber, electrical connections, and air supply are seamlessly integrated.

Durable and resistant to wear, ensuring long-term stable performance.

One-Touch Wire Feeding Control

The welding gun features an intuitive one-button wire feed/stop function.

Enhances efficiency by allowing quick adjustments during operation.

Superior Beam Quality for Deeper Penetration

High energy density and strong penetration ability for consistent, high-strength welds.

Delivers stable, precise results across various metal types and thicknesses.

Stable and Reliable Performance

Self-developed welding control system ensures seamless compatibility with the laser source.

Designed for long-term industrial use with stable, consistent performance.

Customizable Design

Supports custom branding with a personalized human-machine interface (HMI) logo.

Adaptable to specific operational needs and industrial applications.

Specifications

| Model | MFSC-1500HW | MFSC-2000HW |

|---|---|---|

| Laser Power | 1500W | 2000W |

| Cooling Method | Water Cooling | Water Cooling |

| Beam Quality (M²) | ≤1.3 | ≤1.3 |

| Output Mode | Continuous/Pulse | Continuous/Pulse |

| Fiber Cable Length | Customizable | Customizable |

| Operating Voltage | AC 220V/380V | AC 220V/380V |

| Welding Speed | Adjustable | Adjustable |

| Dimensions | Compact Design | Compact Design |

Applications

The MFSC-1500HW and MFSC-2000HW are widely used across industries requiring high-precision, high-efficiency welding, including:

Automotive Manufacturing – Welding of metal body parts, chassis, and structural components.

Sheet Metal Processing – Seamless, clean welding of stainless steel, aluminum, and alloys.

Electronics & Appliances – Precise welding of thin metal parts, enclosures, and heat-sensitive materials.

Aerospace & Aviation – High-strength, lightweight welding solutions for aircraft components.

Custom Fabrication & Repair – Ideal for both large-scale production and specialized repair work.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR