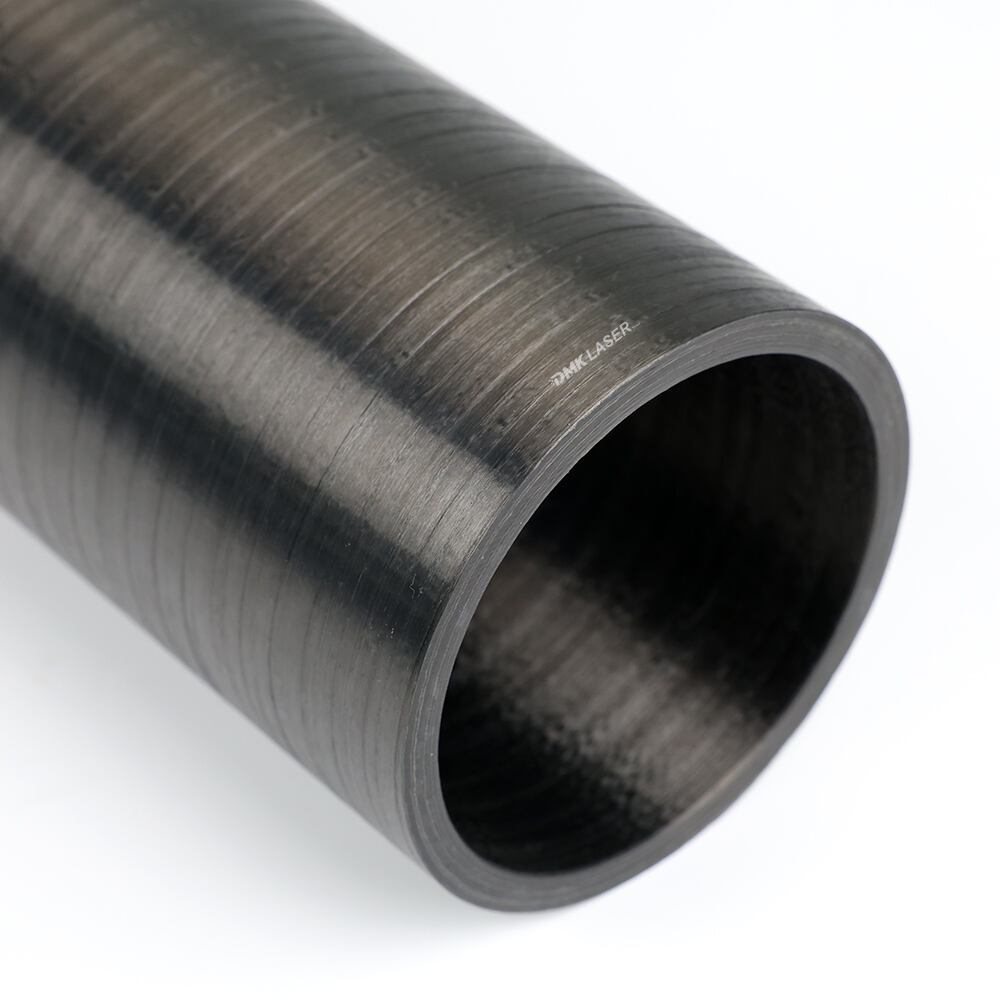

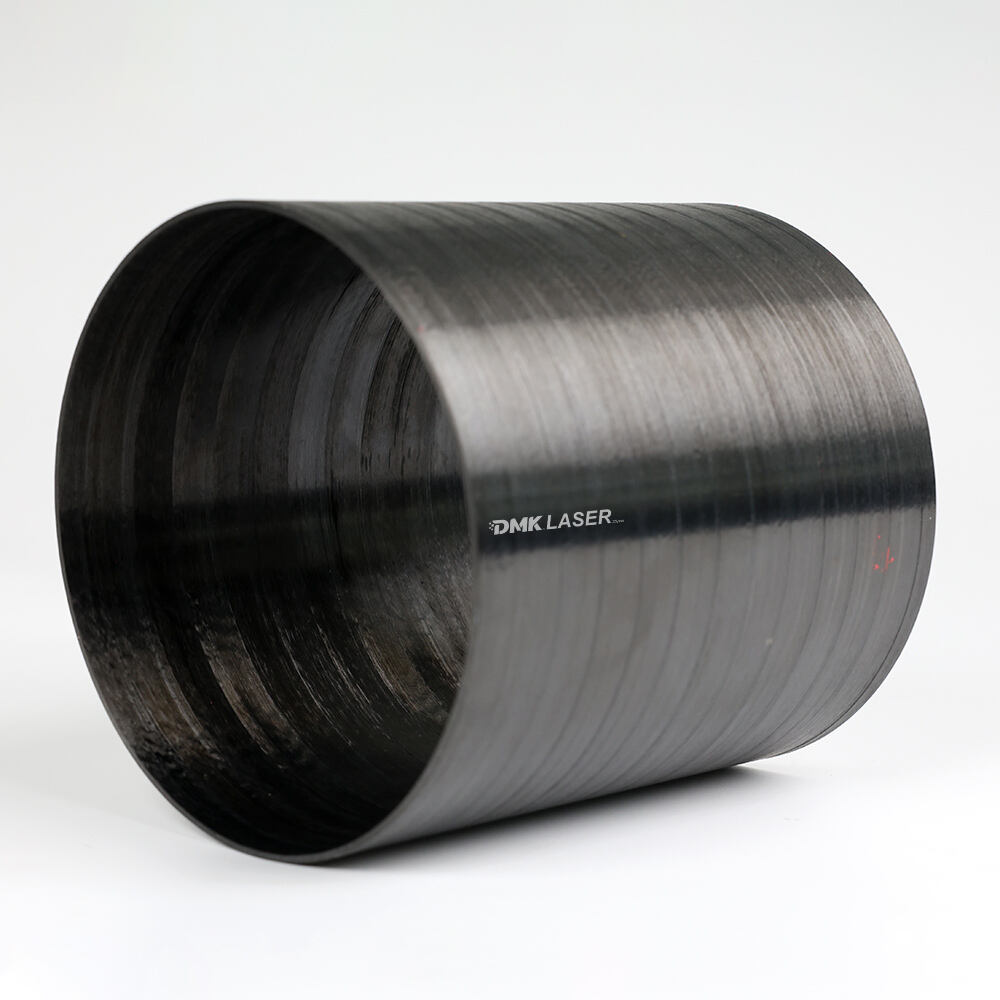

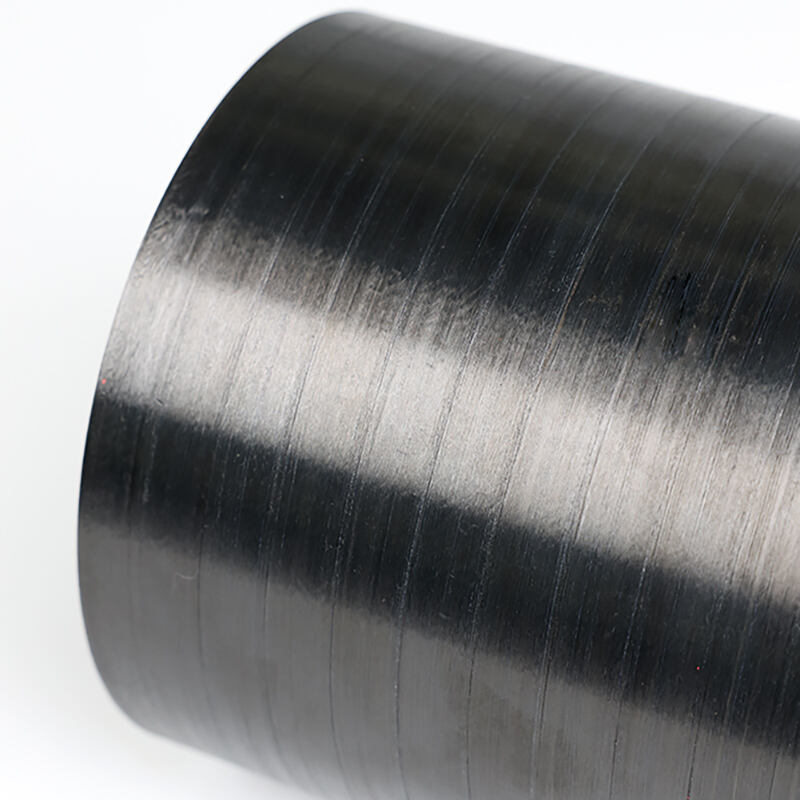

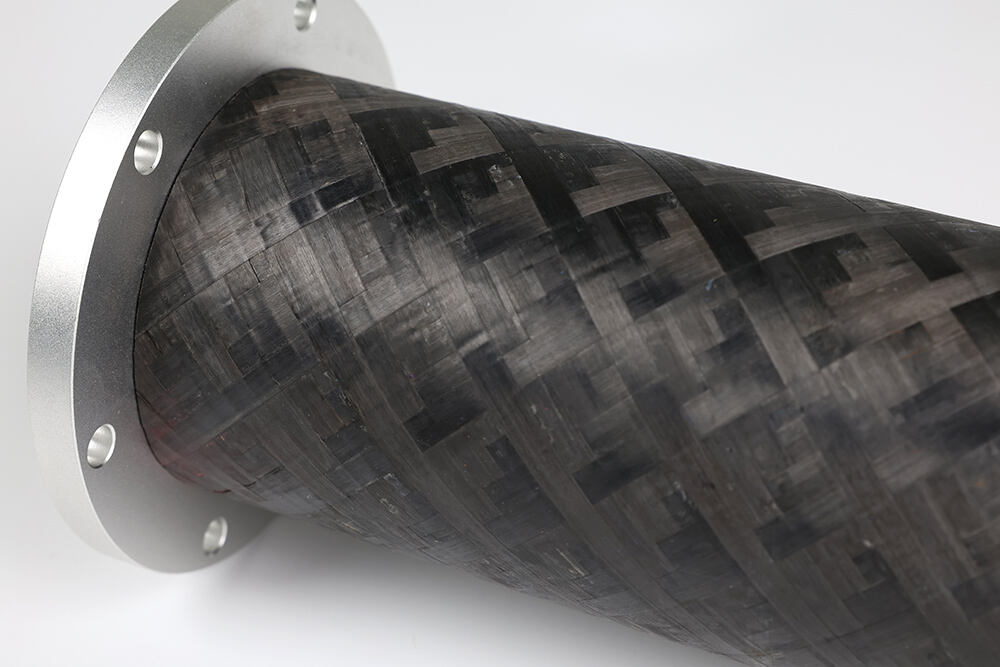

DMK Custom Carbon Fiber Reinforced Thermoplastic Tube – PEEK Composite

Advanced Materials. Engineered Performance. Fully Customizable

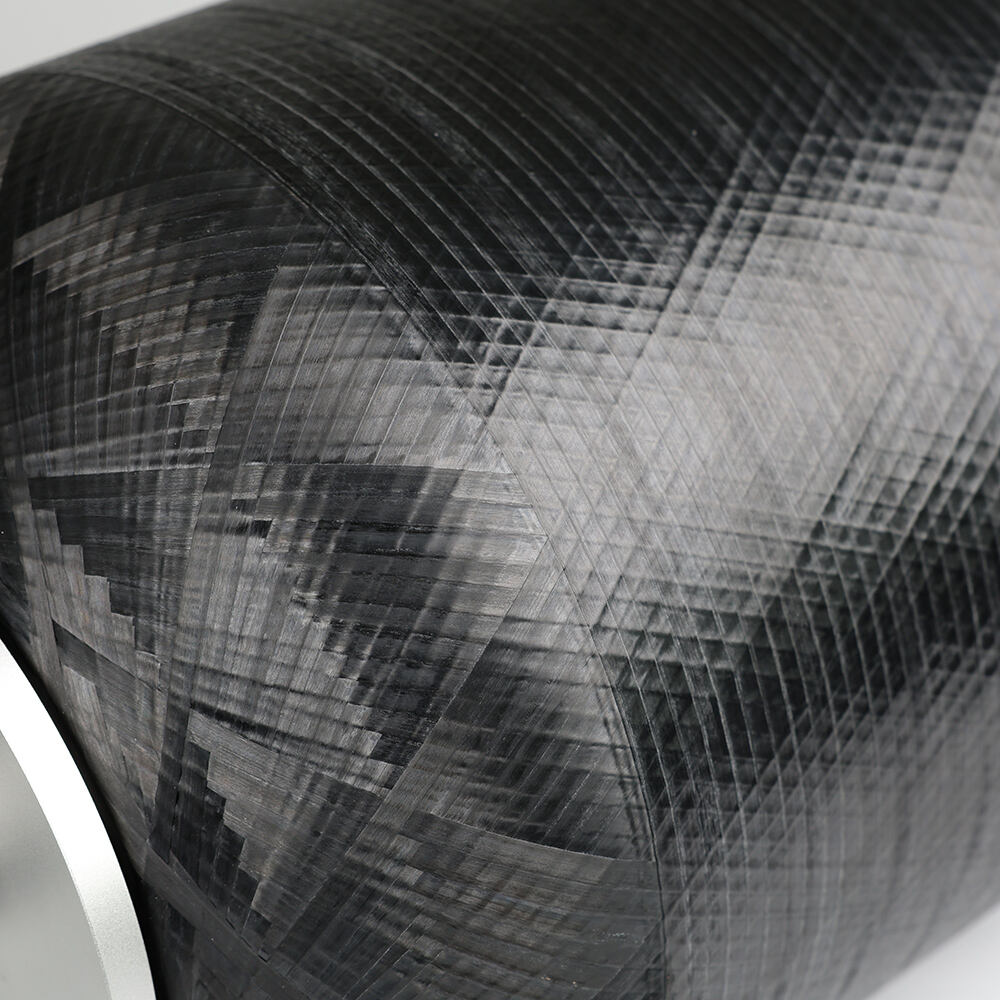

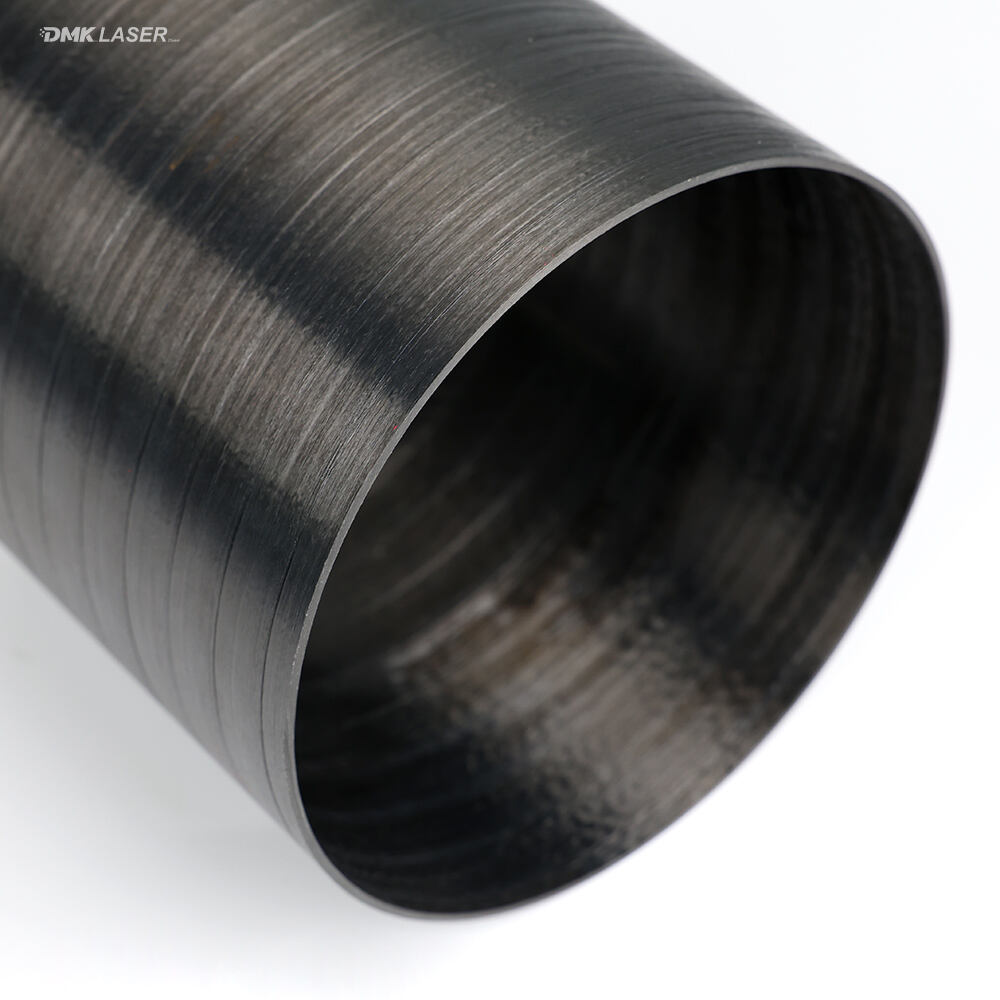

DMK Laser offers high-performance thermoplastic composite tubes reinforced with continuous carbon fiber – ideal for demanding applications where lightweight, strength, and durability are critical. Our tubes are manufactured using a robotic laser-fusion process, combining carbon fiber with PEEK (Polyether ether ketone), one of the highest-performing thermoplastic polymers available.

🔧 Customizable to Your Specifications

We provide fully customizable carbon fiber thermoplastic tubes tailored to your specific requirements:

Diameter

Wall thickness

Length

Mechanical properties (stiffness, strength, flexibility)

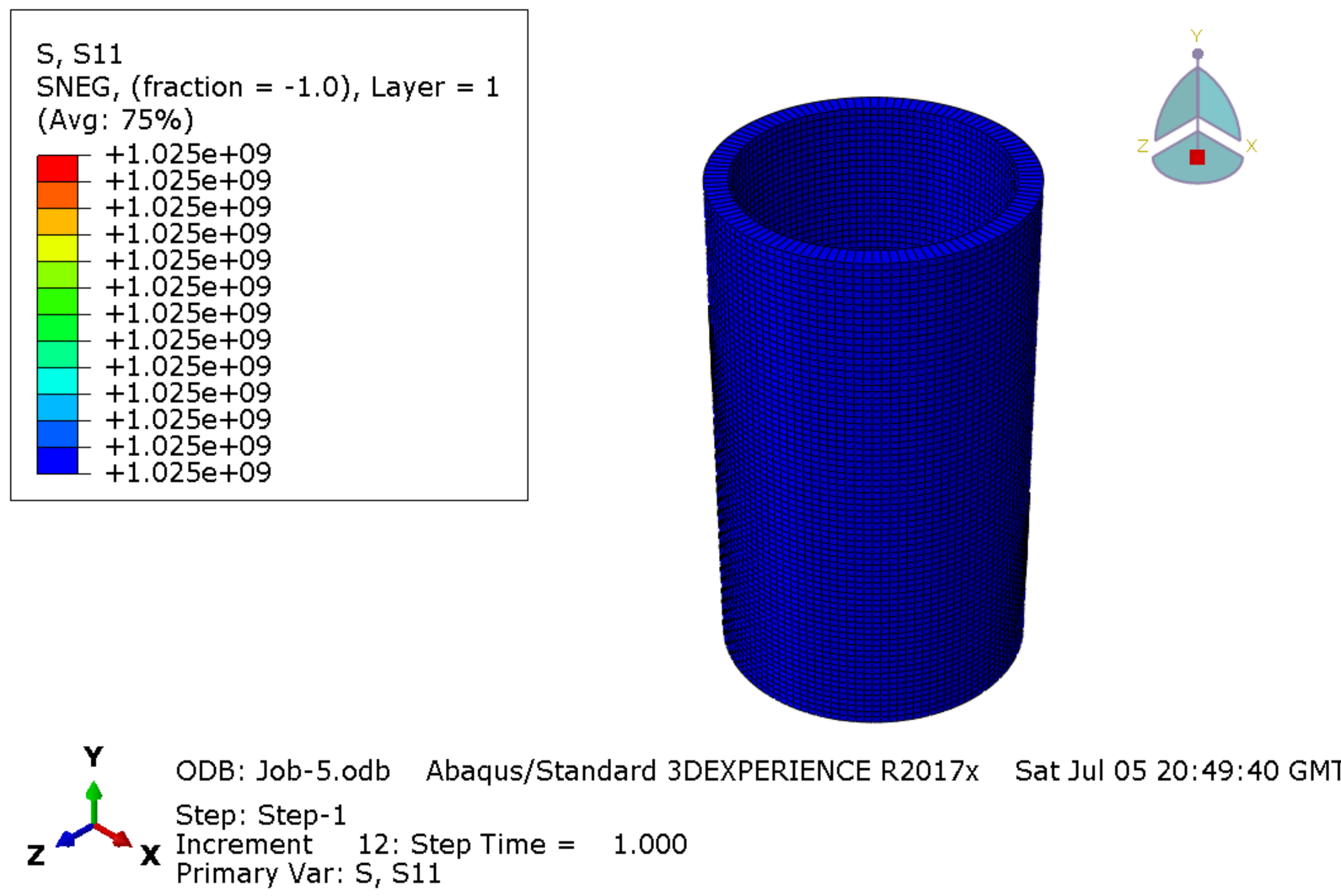

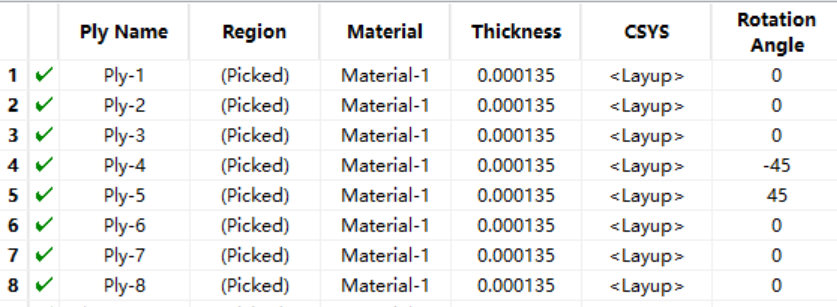

Our engineering team can also design the fiber lay-up configuration based on your required strength and performance parameters, optimizing the balance between flexibility, rigidity, and load-bearing capability.

Whether for prototype development or large-scale production, we have the technology, machinery, and expertise to support your project from concept to delivery.

⚙️ Manufacturing Technology

Our tubing is manufactured from unidirectional carbon fiber and PEEK tape, laser-fused layer by layer using an automated robotic system, resulting in:

A fully bonded, smooth-bore structure

Exceptional chemical resistance (including oilfield chemicals)

High temperature resistance

Low permeability

Tunable mechanical properties by adjusting fiber lay angles

Why Choose DMK Thermoplastic Composite Tubes?

✅ Superior Strength-to-Weight Ratio

✅ Corrosion & Chemical Resistance

✅ Excellent Fatigue & Impact Resistance

✅ High Thermal Stability

✅ Low Maintenance Requirements

✅ Custom Lay-Up for Optimized Performance

🛠️ Reinforcement Applications

Our CFR thermoplastic tubes are also ideal for reinforcing existing metal or polymer structures, such as:

Hydraulic cylinders

Pipeline systems

Structural components in automotive or aerospace

By combining the tribological benefits of metals with the mechanical performance of CFR-TP, hybrid structures achieve enhanced durability, lower weight, and extended service life.

🚀 Applications Across Industries

Our thermoplastic carbon fiber tubes are already being used — or are ideal — in a wide range of industries where strength, weight reduction, and durability matter most:

🚴 Bicycle frames

Lightweight and strong tubing ideal for high-performance bikes and custom builds.

🛠️ Tool shafts

Reinforced shafts and handles for tools requiring stiffness and impact resistance.

🚗 Automotive steering systems

Used in steering rods, cross members, and lightweight vehicle structures.

⚙️ Bearings, bushings, and seals

Resilient under heavy loads and ideal for wear-prone industrial components.

🛢️ Oil & gas composite pipes

Corrosion-resistant pipes and liners for challenging chemical and pressure conditions.

🌐 Aerospace and industrial machinery

Precision-engineered tubing for structural parts, robotics, and automation systems.

🔩 Precision parts in high-load environments

Custom tubing used in prototypes and machinery where failure is not an option.

🩺 Medical devices and surgical tools

Micro-diameter tubes for endoscopic tools, surgical instruments, or structural supports used in minimally invasive procedures.

♻️ Sustainable & Recyclable

Thermoplastic composites like PEEK/carbon fiber are recyclable, allowing your product to support sustainability goals without compromising on technical performance.

📦 Production Capacity

With industrial-grade equipment and a skilled technical team, DMK Laser can support batch orders, OEM customization, and rapid production of high-spec composite tubes.

📞 Get a Quote

Have a specific project in mind? Contact our team to discuss your requirements. We’re ready to help you design, prototype, and produce CFR TP tubes tailored to your application.

More Sample Displays

| High speed motor rotor sleeve | ||

|

|

|

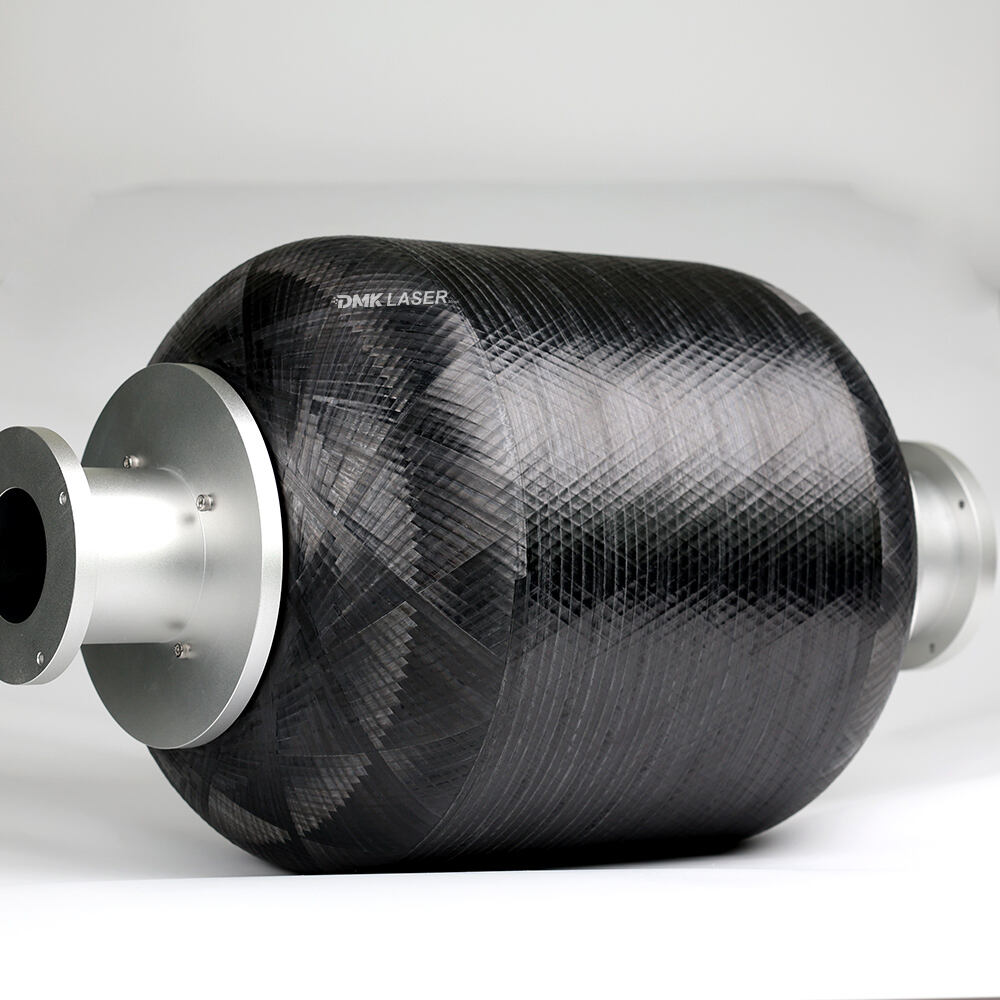

| Pressure vessel/hydrogen storage bottle | ||

|

|

|

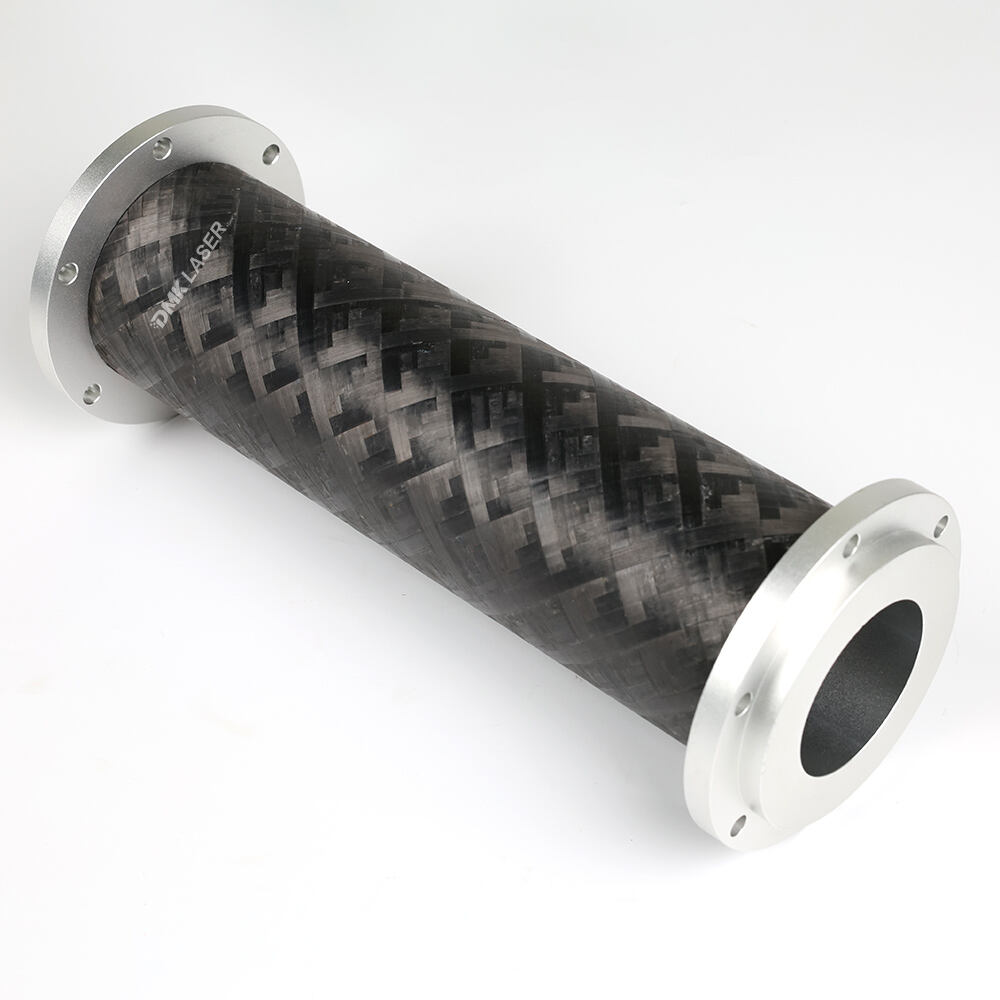

| Power transmission shaft | ||

|

|

|

| Subsea/Land Oil Pipeline | ||

|

|

|

| Surgical robot instrument rod | ||

|

|

|

|

Carbon fiber sailboat mast

|

Aircraft engine nacelle skin

|

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR