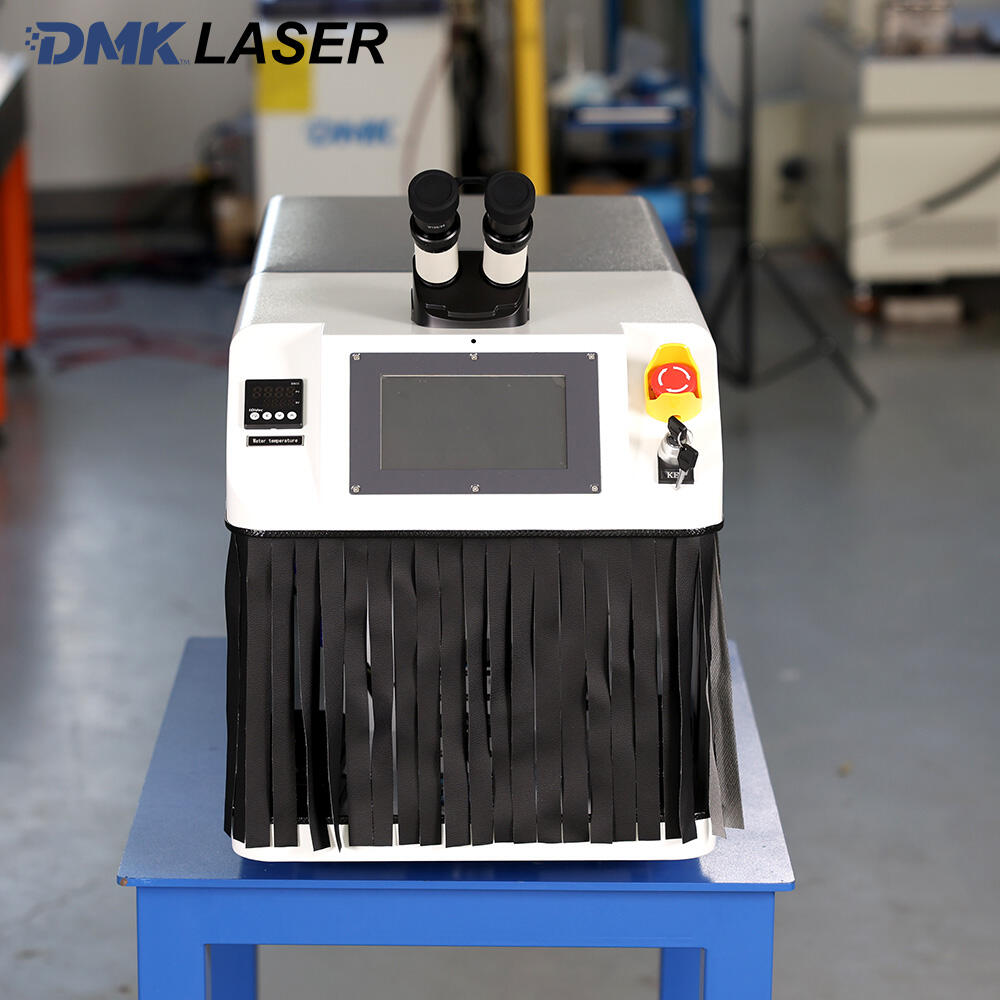

DMK 150W Jewelry Laser Spot Welder

Product Overview

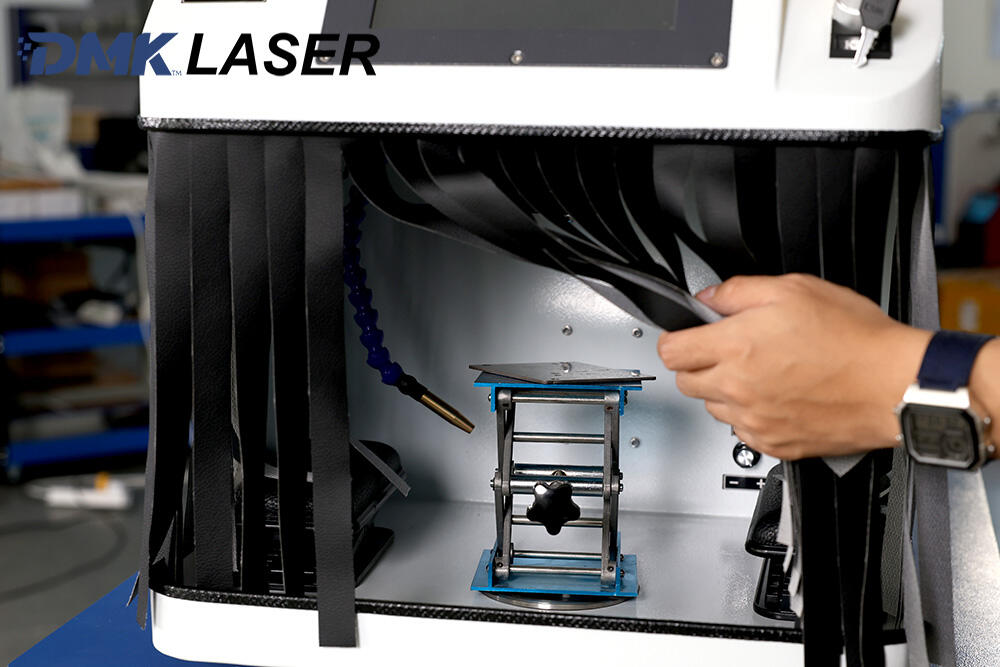

Looking for a professional-grade jewelry welding solution that combines precision, speed, and ease of use? The HB-SW Series Laser Spot Welder is your ultimate choice. Designed for jewelers, repair shops, and small-scale manufacturers, this machine delivers high-quality welds on the tiniest components without damaging stones or delicate settings. Perfect for gold, silver, titanium, platinum, and more!

Why Choose HB-SW Laser Spot Welder?

✔ Perfect for Jewelry – Easily handle ring resizing, bracelet repairs, and fine detailing.

✔ Safe & Reliable – Built-in automatic light shielding to protect your eyes.

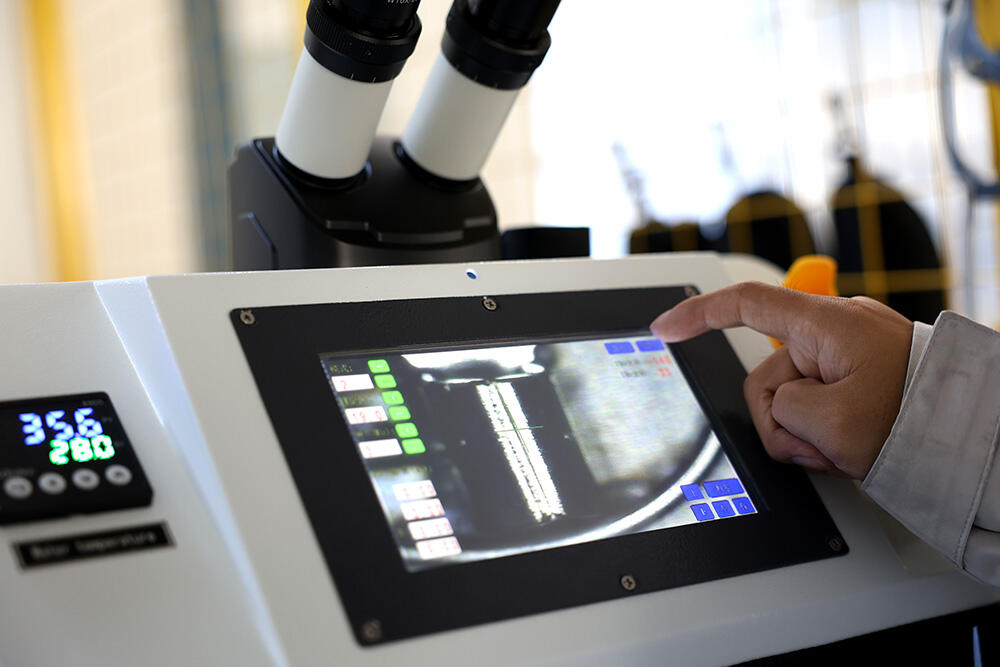

✔ Precision Control – Adjust pulse width, frequency, and energy to achieve flawless results.

✔ Works on Multiple Metals – Gold, platinum, titanium, silver, copper, aluminum, and stainless steel.

✔ Long-Lasting Performance – 24-hour continuous operation with up to 10,000 hours of maintenance-free service.

Core Features

Adjustable Welding Settings for diverse materials and applications

Imported Ceramic Reflector for superior durability and optical performance

Ergonomic Design for comfortable, fatigue-free operation

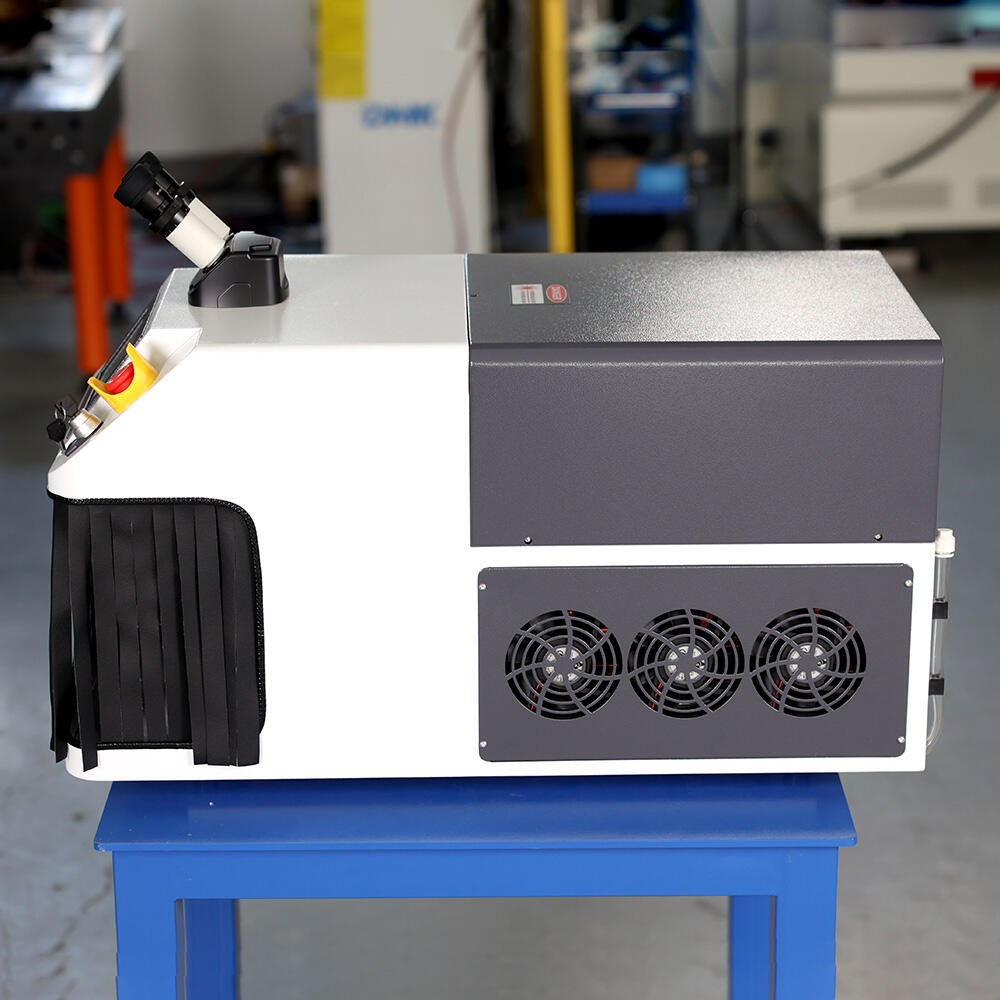

Compact & Professional Build optimized for workshop use

|

|

|

|

Technical Specifications

| Laser Source | Nd³:YAG |

| Wavelength | 1064 nm |

| Pulse Frequency | Up to 115 Hz (adjustable) |

| Pulse Width | 1.5 – 20 ms adjustable |

| Single Pulse Energy | 40 J |

| Rated Laser Power | 150 W |

| Focused Beam Diameter | 0.12 mm |

| Microscope Ratio | 10X |

| Focal Length | 110 mm |

| Power Supply | AC 220 V, single-phase |

| Power Consumption | 3 kW |

| Environment | 5°C – 30°C, humidity < 85% |

| Continuous Working Time | 24 hrs |

| Shield Gas Connection | Argon, quick connection |

Applications

Ideal For

Jewelry workshops

Eyewear repair

Dental labs (titanium dentures)

Electronic components

Precision welding of small metal parts

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR