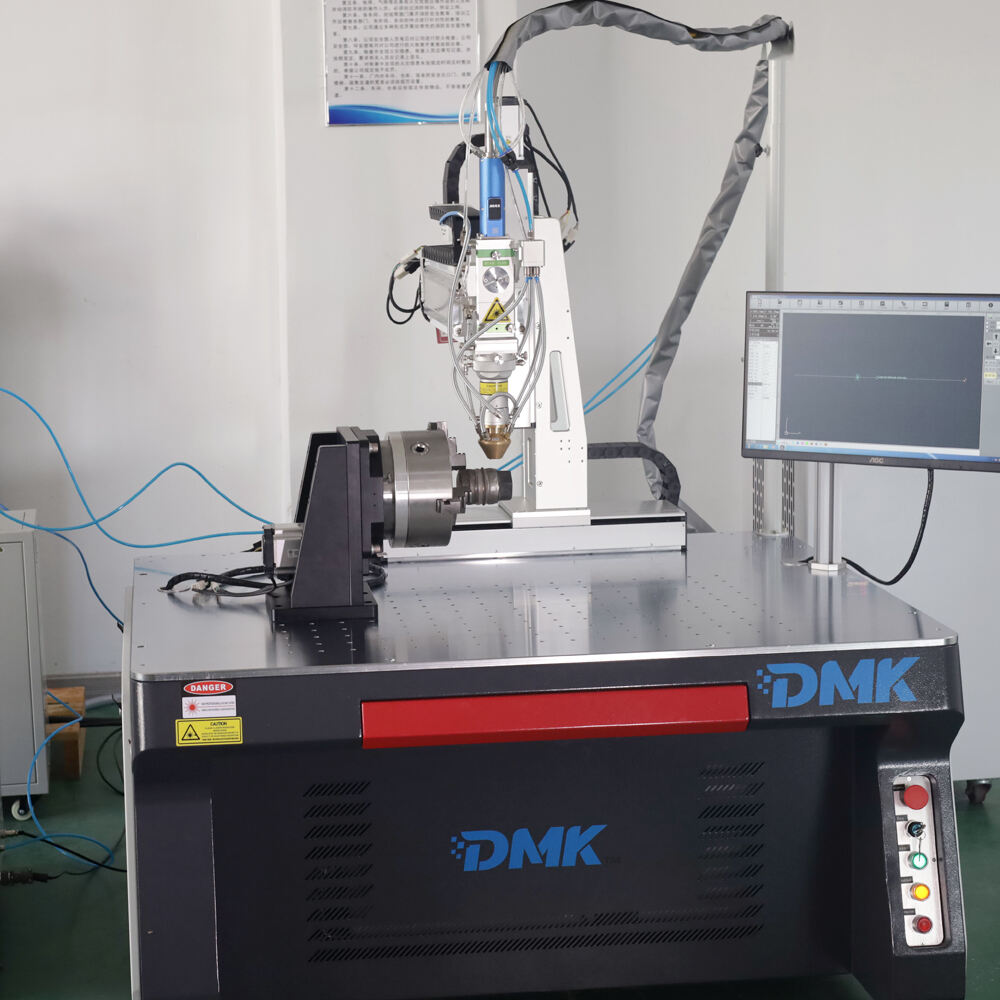

Cladding machine

Product Description

The cladding machine is a high-performance surface strengthening and repair device based on laser cladding technology. Its core process uses a high-energy laser beam to metallurgically bond alloy powder with the substrate. It is compatible with a variety of materials, including metals and ceramics, and supports both flat and three-dimensional curved surface processing. The cladding layer is dense, wear-resistant, and highly corrosion-resistant.

The equipment features a small heat-affected zone, low deformation, and controllable precision, with a powder utilization rate of up to 90%. Compared to traditional processes, the processing efficiency is increased by more than three times, significantly reducing production costs.

It is widely used in aerospace, energy and power, mold manufacturing, and other fields, enabling part repair, surface modification, and additive manufacturing, thereby extending equipment life and reducing replacement costs.

Product Parameters

Other Details

-

Worktable

- Customizable Size: Non-standard dimensions tailored to specific applications.

-

Model Options:

- Standard desktop model

- Standard enclosed model

- Frame type

- Cast iron platform type

- Robotic model

- Multi-Functionality: Interchangeable heads for laser cladding, hardening, and welding (including inner bore and high-speed cladding). Protective enclosures available upon request.

-

Laser Source

- Customized continuous fiber laser with high electro-optical efficiency and anti-reflective features.

- Optimized beam quality ensures uniform energy distribution, higher powder utilization, and refined cladding surfaces.

- Supports power outputs of 900W or higher for cladding and hardening tasks.

-

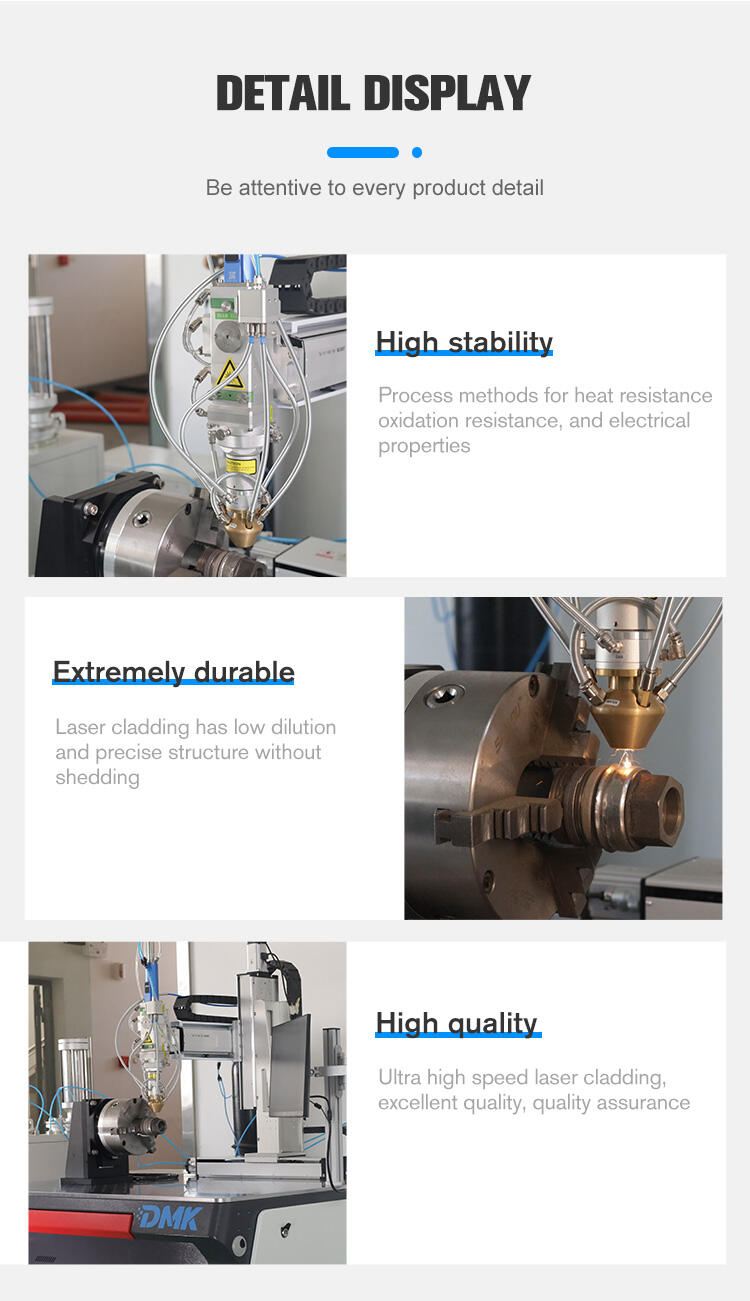

Laser Cladding Head

- Suitable for surface and inner bore laser cladding and hardening.

- Compact and easy to maintain, delivering fine cladding surfaces with excellent forming quality.

-

Powder Feeder

- Available in standard, dual-barrel, compact, and mechanical types.

- Features touch-screen or mechanical button control, remote operation, and optional heating, dehumidifying, and stirring functions.

-

Chiller

- Internal circulation system for cooling and maintaining stable temperatures.

- Ensures consistent laser performance in high or low-temperature environments.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR