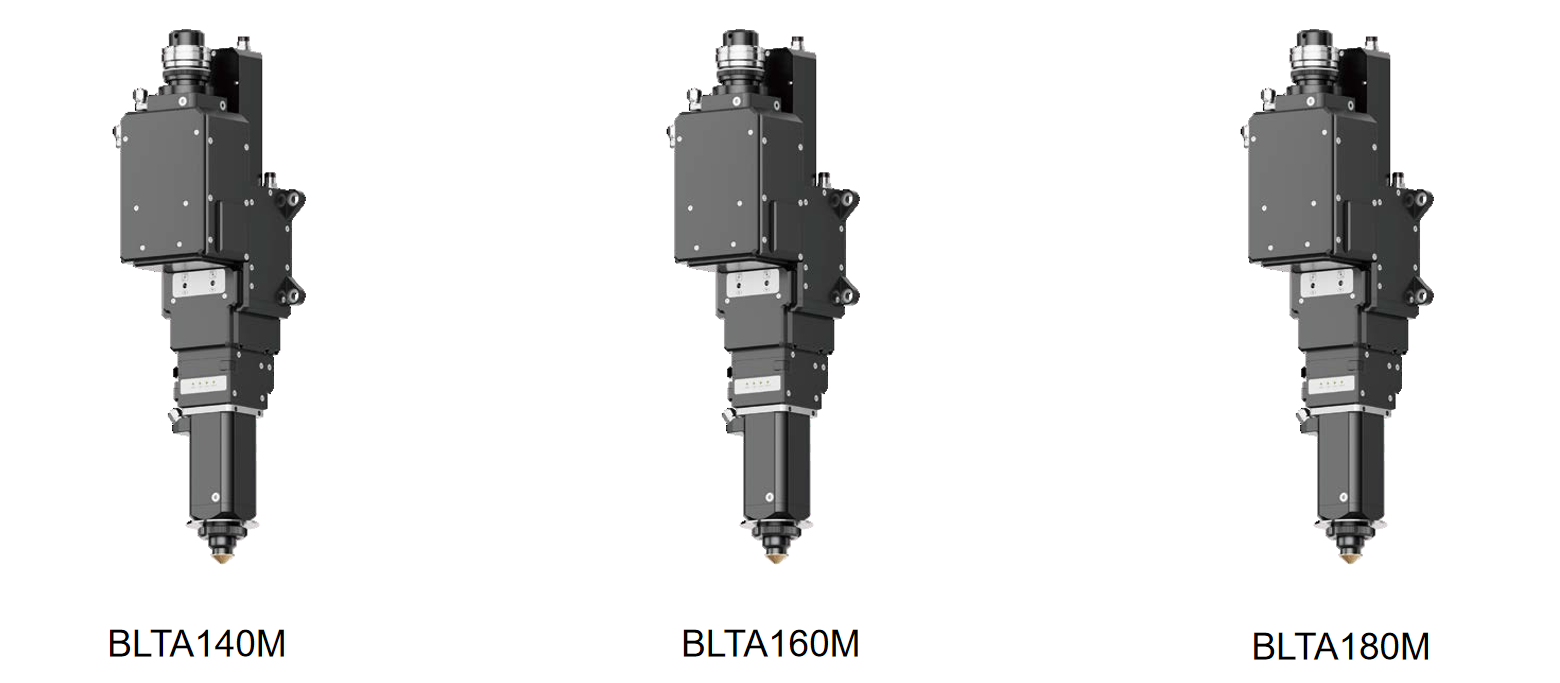

BOCHU BLTA Series Intelligent Monitoring Flat Laser Cutting Head (BLTA140M/BLTA160M/BLTA180M)

Product Brief

This is BOCHU’s high-power intelligent flat cutting head, integrating functions like intelligent piercing, process monitoring, and multi-dimensional monitoring (nozzle/kerf width). Compatible with 50-120kW power equipment, it balances processing efficiency and operational safety, serving as a core accessory for industrial high-power cutting scenarios.

Product Features

- Intelligent Piercing for Efficiency: Real-time control of the piercing process via sensors reduces piercing time, significantly boosting processing efficiency and cutting costs.

- Full-Process Intelligent Monitoring: Built-in sensors track cutting status in real time, enabling unattended stable processing and reducing manual intervention.

- Multi-Dimensional Status Monitoring: Covers nozzle offset (intelligent alert + adjustment), nozzle quality (real-time wear detection), and kerf width closed-loop control (ensures consistent cutting results), lowering maintenance costs.

- High-Power Wide Compatibility: Covers 50-120kW power range, paired with a 300mm focal length, compatible with mainstream high-power laser equipment and suitable for thick plate processing.

Product Parameter Table

| Cutting Head Model | BLTA140M | BLTA160M | BLTA180M |

|---|---|---|---|

| Technical Specs | |||

| Laser Power (kW) | ≤50 | ≤100 | ≤120 |

| Focal Length (mm) | 300 | 300 | 300 |

| Fiber Interface | Q+/ADQ | Q+/ADQ | ADQ≥24 |

| Cutting Speed (mm/min) | 500 | 500 | 500 |

| Height Adjustment Range (mm) | ±70~100 | ±70~100 | ±70~100 |

| Repeat Positioning Accuracy (mm) | 0.01 | 0.01 | 0.01 |

| Laser Wavelength (nm) | 1030-1090 | 1030-1090 | 1030-1090 |

| Max Air Pressure (Bar) | 25 | 25 | 25 |

Product Application Fields

- Flat cutting for high-power laser equipment

- Thick metal plate processing

- Batch cutting of industrial components

- Unattended intelligent cutting production lines

Product FAQ

-

What is the core advantage of the intelligent piercing function? Answer: It controls the piercing process in real time via sensors, reducing piercing time, significantly boosting processing efficiency and cutting costs.

-

What functions does the multi-dimensional monitoring system include? Answer: It includes nozzle offset monitoring (intelligent alert + adjustment), nozzle quality monitoring (real-time wear detection), and kerf width closed-loop control (ensures consistent cutting results).

-

What is the power compatibility range for different models? Answer: BLTA140M is compatible with ≤50kW, BLTA160M with ≤100kW, and BLTA180M with ≤120kW.

-

How does process monitoring enable unattended processing? Answer: Built-in sensors track cutting status in real time; the system automatically adjusts or alerts when anomalies occur, eliminating the need for continuous manual monitoring.

- Can the height adjustment range adapt to plates of different thicknesses? Answer: The height adjustment range is ±70~100mm, which can adapt to the processing needs of plates with different thicknesses.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR