BCG3 Series Network Galvo Controllers

Product Description

The BCG3 Series Network Galvo Controllers are designed for precise galvo head and laser control in demanding industrial applications. Using Ethernet communication, they support both standard and digital galvo protocols, enabling high-precision marking, scribing, cutting, and welding.

BCG301 – Controls a single galvo and single laser, suitable for static processing such as marking, scribing, cutting, and welding.

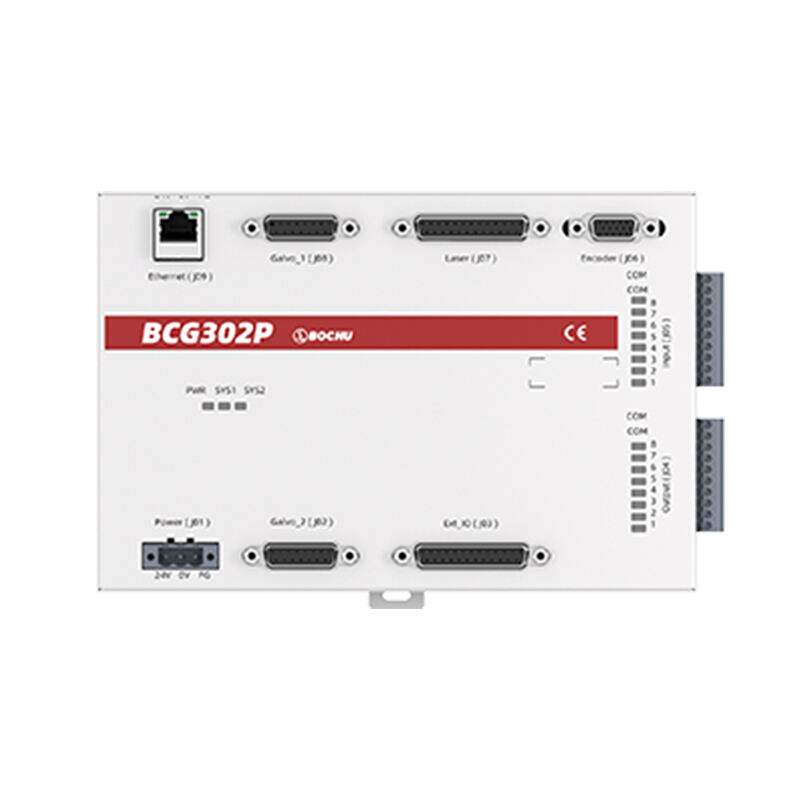

BCG302P – Supports single-laser dual-galvo beam-splitting processing or incremental encoder input for on-the-fly (flying) processing.

Key Features

Rotary & Linear On-the-Fly Processing – Supports DD motors, linear axes, and rotating workpieces with 10 μs encoder real-time compensation.

Precision Laser Triggering – Achieve finer laser on/off granularity and more accurate beam positioning.

Custom Development Support – Compatible with TCP and DLL secondary development libraries for tailored industry solutions.

ScanAhead Control – Improves galvo position accuracy and spot size control.

3D Galvo Compatibility – Supports pre-focusing 3D galvos and post-focusing 2.5D galvos for surface machining and relief engraving.

UltraScan Software – Bochu’s dedicated galvo processing control software for calibration, process handling, and multi-galvo, multi-layout production via Ethernet.

Advantages

High-speed, low-latency Ethernet communication.

Flexible control for both static and on-the-fly operations.

Enhanced processing quality through advanced position compensation and spot control.

Broad laser compatibility, including fiber CW, QCW, and ultrafast lasers.

Supports curved-surface and depth-variable machining.

|

|

Technical Specifications

| Parameter | Value |

|---|---|

| Models | BCG301 / BCG302P |

| Galvo Interface Count | 1 |

| Encoder Interface Count | 0 |

| Galvo Protocols | XY2-100, BC2-100 |

| Laser Types Supported | Fiber CW, QCW, Ultrafast |

| 24V IO | 8 in / 8 out |

| 5V IO | 8 in / 8 out |

| DAC | 2 channels, 0–10V / 16-bit |

| ADC | 2 channels, 0–10V / 12-bit |

Precision marking

Fine-line scribing

Laser cutting

Laser welding

3D/curved surface engraving

On-the-fly processing for rotary or linear motion systems

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR