A200MS Fiber Laser Cutting Head - 2000W Compatible + Precision Focus - For Flat Cutting

Product Description

The A200MS Fiber Laser Cutting Head, derived from the German A-cutter brand, is an ideal mid-power solution designed for fiber laser cutting applications within 2000W, specifically tailored for flat-panel processing scenarios.

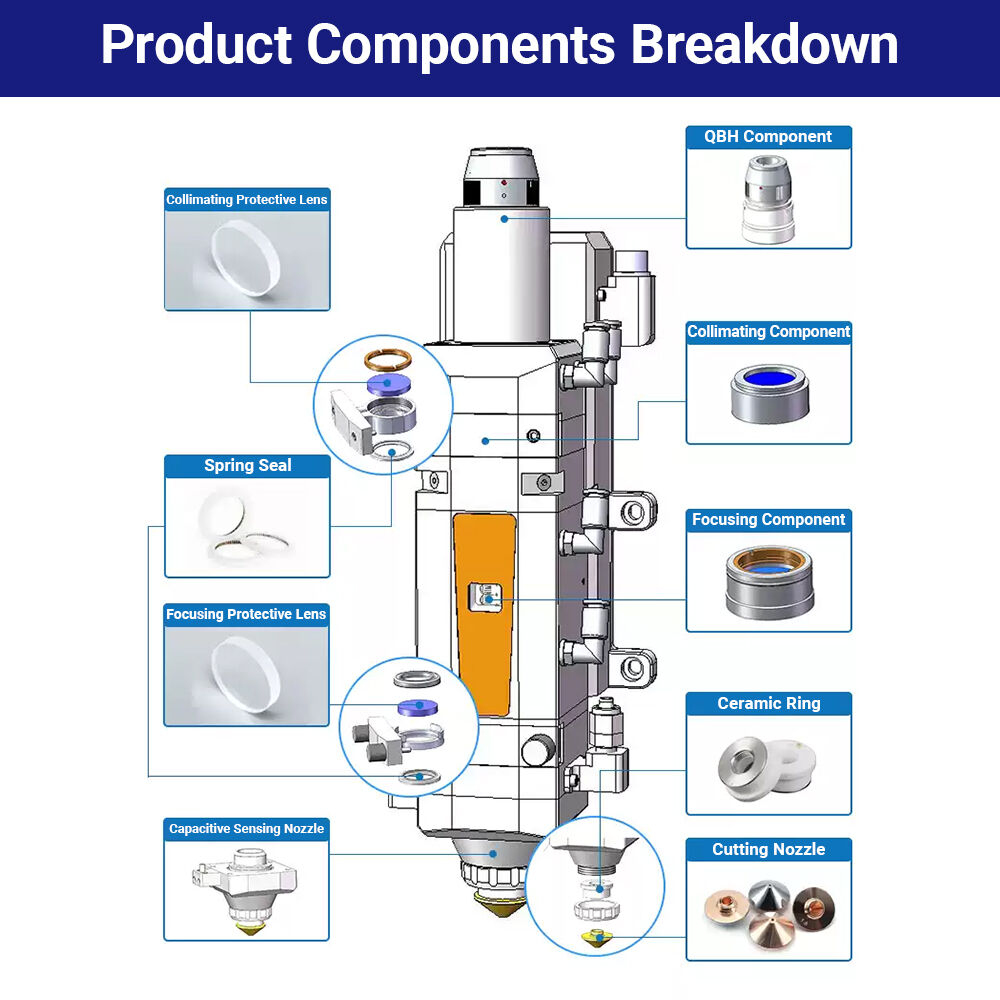

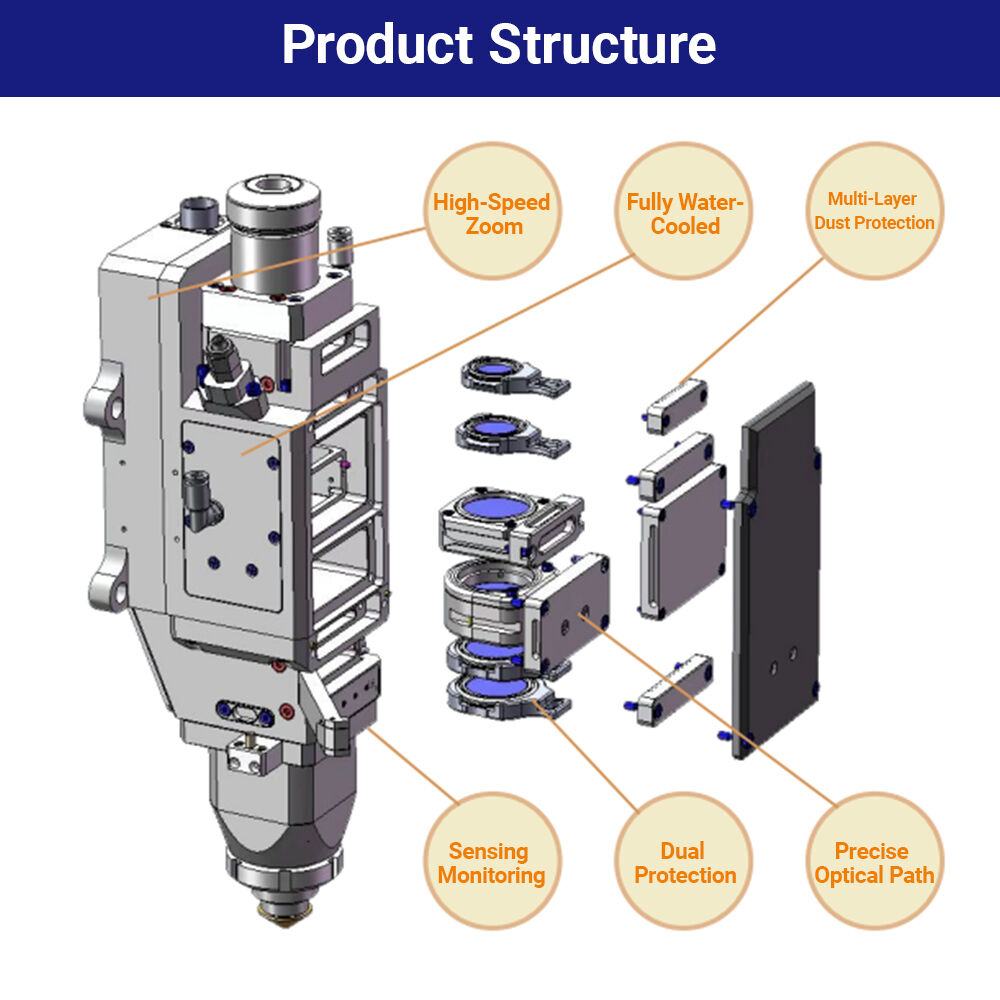

Equipped with a D30 composite lens group to integrate the laser beam, with a laser wavelength of 1064nm, the product features a complete water-cooling structure and high-grade dustproof design, enabling long-term stable operation under high power. It consists of five core units: fiber interface, collimation module, focusing module, protective lens module, and nozzle module. Supporting focus adjustment of X-Y ±1mm and Z-axis -6mm~6mm, it covers a wide range of cutting processes and is compatible with various fiber lasers.

Adopting precision optical components and mechanical processing, it offers excellent and stable beam quality. The protective lens can effectively avoid damage to the focusing lens from slag return, extending service life. With a nozzle aperture of 1mm-4mm, combined with high-purity cutting gas, it can achieve high-quality kerfs. Widely used in mid-power flat-panel laser cutting fields, it meets the precision cutting needs of metal materials.

Product Parameters

| Parameter Category | Specific Parameters |

|---|---|

| Core Compatibility Parameters | - Maximum Applicable Laser Power: 2000W - Laser Wavelength: 1064nm - Fiber Interface Type: QBH - Applicable Scenario: Flat-panel Cutting within 2000W |

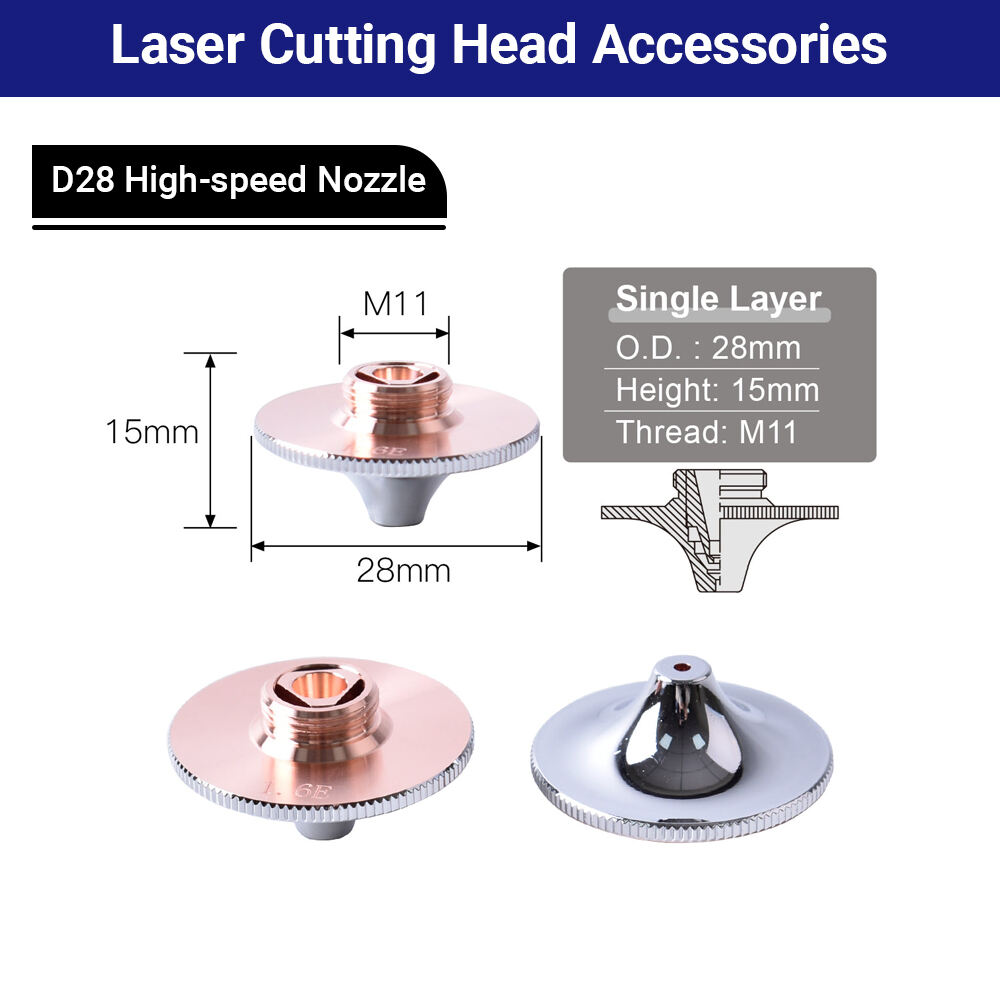

| Optical Parameters | - Focus Lens Specification: Dia=30mm, F=125mm - Collimation Lens Specification: Dia=30mm, F=100mm - Maximum Light-passing Hole Diameter: 26mm - Nozzle Aperture: 1mm-4mm |

| Adjustment Parameters | - Focus X-Y Adjustment Range: ±1mm - Focus Z Adjustment Range: -6mm~6mm |

| Physical and Installation Parameters | - Cutting Head Weight: ≤2.5kg - Maximum External Dimension of Cutting Head: 62mm - Cooling Water Pipe Diameter (Outer): 6mm |

| Operating Parameters | - Minimum Water Cooling Flow Rate: 1.8 L/min - Water Cooling Inlet Pressure: 170-520kPa - Recommended Cutting Gas Purity: Oxygen 99.95%, Nitrogen 99.99%, etc. |

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR