800W Air-Cooled Continuous Fiber Laser

Product Description

Power Meets Portability. For Serious Industrial Demands.

The YDFL-800-CW-SM-A-HW is an air-cooled, single-mode continuous wave fiber laser designed for robust industrial performance. With its compact build and impressive 800W output, it offers an ideal balance of power, precision, and integration flexibility—perfect for laser welding, cutting, and cleaning applications.

Key Features

|

High Power, Compact Build Delivers 800W of stable power in a space-saving air-cooled unit. No chiller required. |

|

|

Superior Beam Quality With an M² ≤ 1.5, the laser ensures precision and consistency in high-demand operations. |

|

Stable Output Power instability ≤ 3%, ensuring reliable results over extended operation. |

|

|

Red Guide Laser for Alignment Built-in 0.9 mW red light assists in quick and safe optical alignment. |

|

Versatile Control Options Supports RS232 communication, analog (0-10V), and TTL trigger control—easy to integrate into automation lines. |

|

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | YDFL-800-CW-SM-A-HW |

| Operation Mode | Continuous Wave (CW) / Quasi-CW |

| Rated Power Output | 800W |

| Wavelength | 1080 ±10 nm |

| Beam Quality (M²) | ≤ 1.5 |

| Polarization | Random |

| Max Modulation Frequency | 5 kHz |

| Power Tuning Range | 10% – 100% |

| Fiber Core Diameter | 14 μm |

| Delivery Head Type | QBH (QCS optional) |

| Cable Length | 5 meters standard (customizable) |

| Cooling Method | Air-cooled |

| Operating Voltage | 220V ±10% / 50–60Hz |

| Max Power Consumption | 2800W |

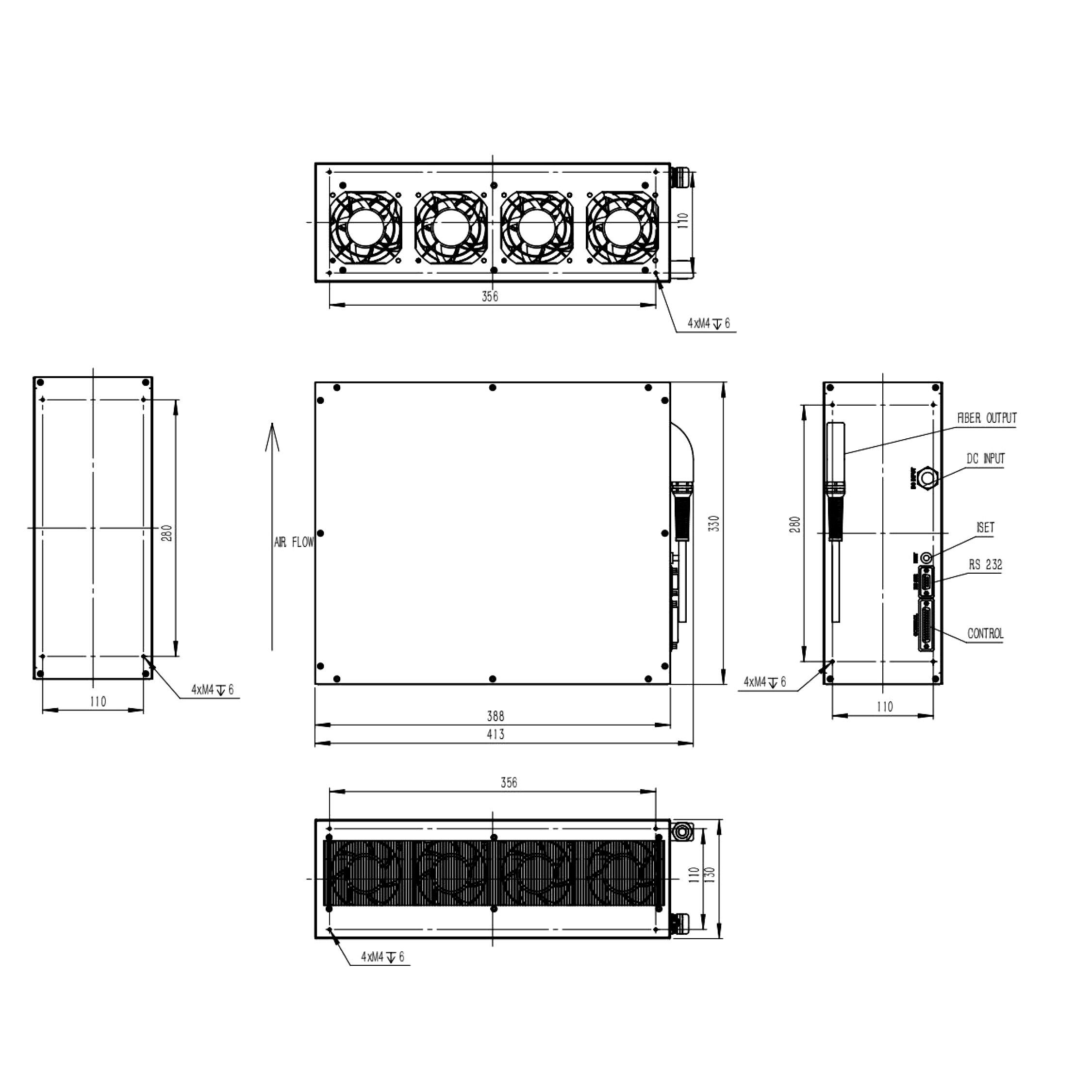

| Dimensions (L×W×H) | 388 × 330 × 130 mm |

| Weight | ≤ 17 kg |

| Operating Temperature | 0°C to +40°C |

| Storage Temperature | -20°C to +60°C |

| Humidity Range | 10% – 85% RH (non-condensing) |

Application

Laser Welding: Suitable for stainless steel, carbon steel, aluminum, and other metals with high seam quality and low distortion.

Laser Cleaning: Removes paint, rust, oil, and oxide layers with zero damage to base materials.

Laser Cutting: Efficient for thin-to-medium thickness sheet metals with clean and burr-free edges.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR