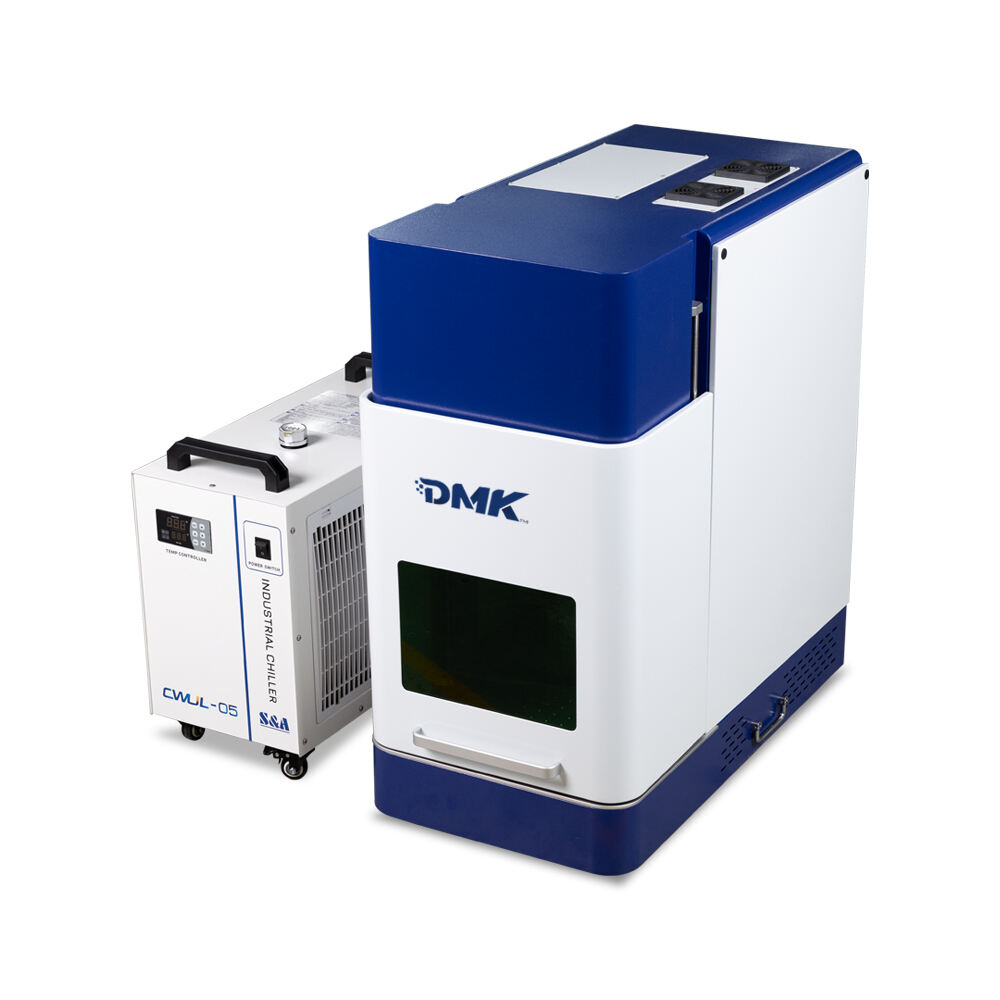

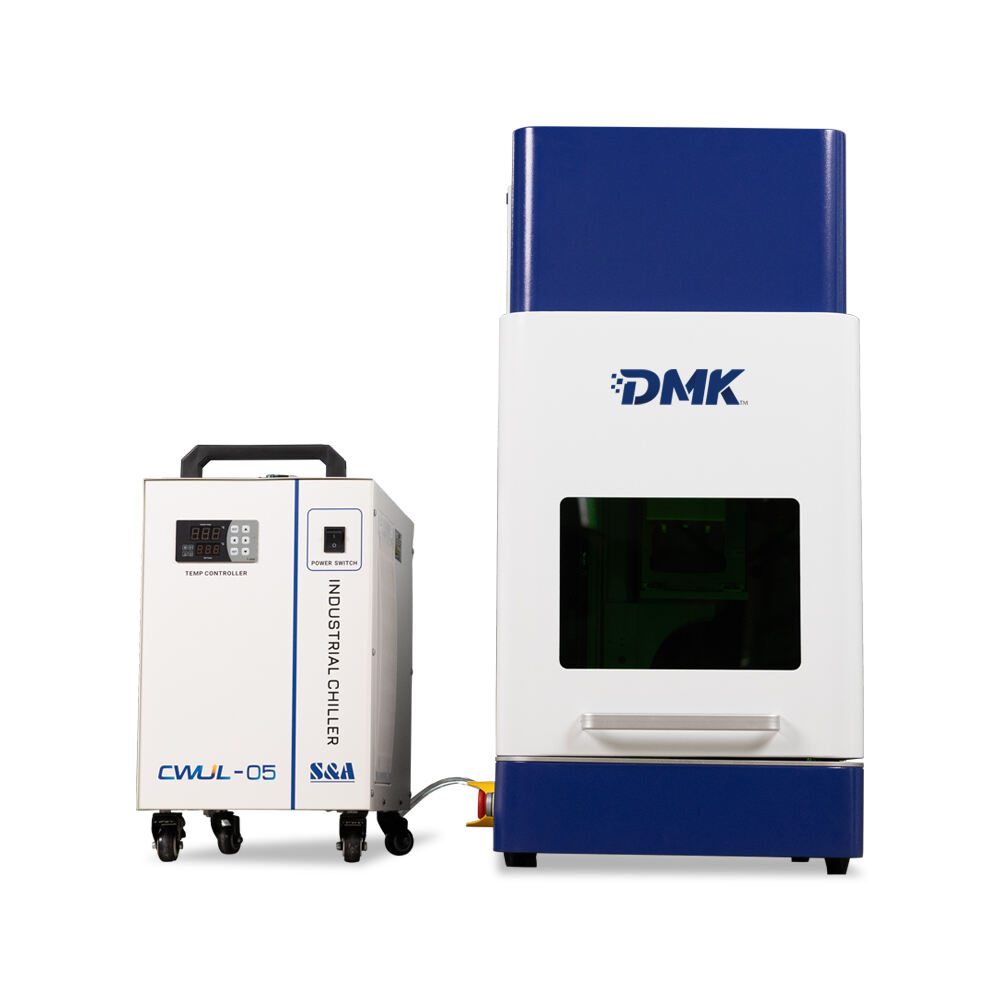

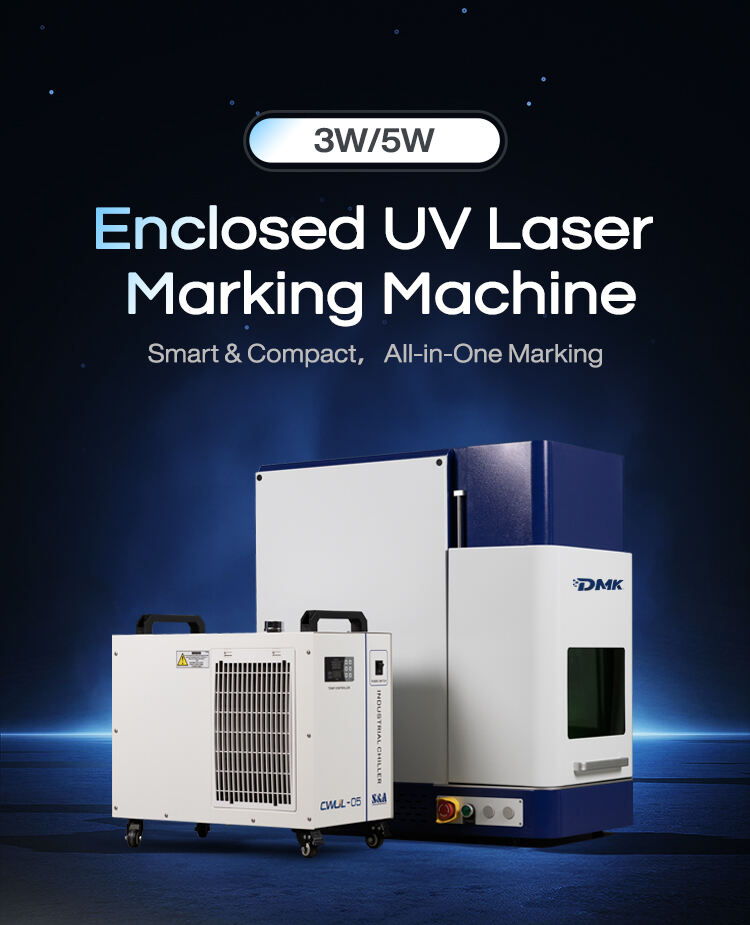

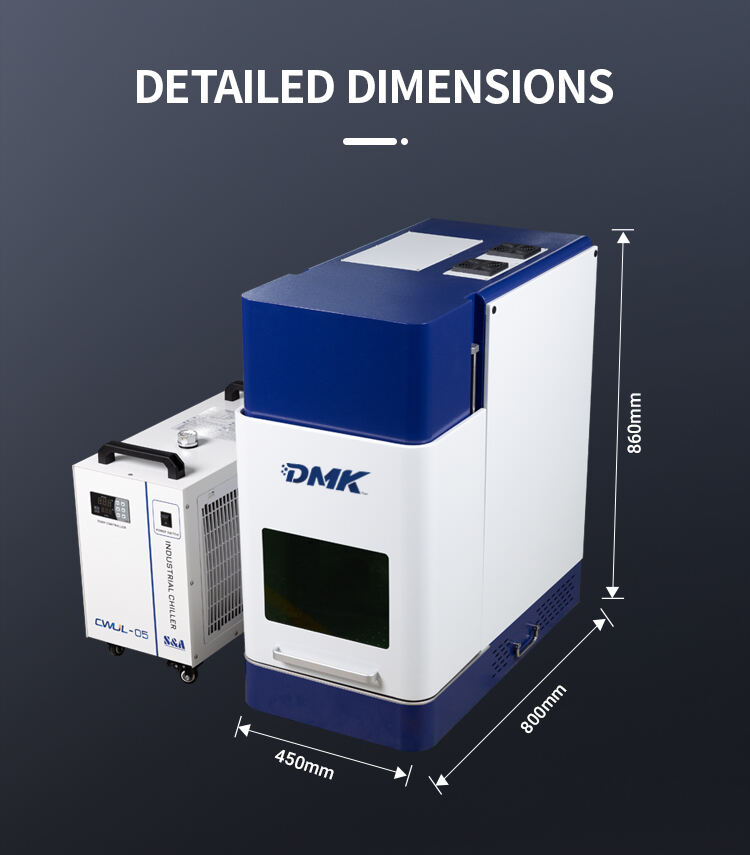

5W UV Laser Marking Machine

The UV laser marking machine is part of the laser marking machine series, so its working principle is largely similar to that of general laser marking machines-both use laser beams to create permanent marks on the surfaces of various materials. The marking effect is achieved by short-wavelength lasers directly breaking the molecular chains of materials, thereby revealing the desired etched patterns and text.

Key Features

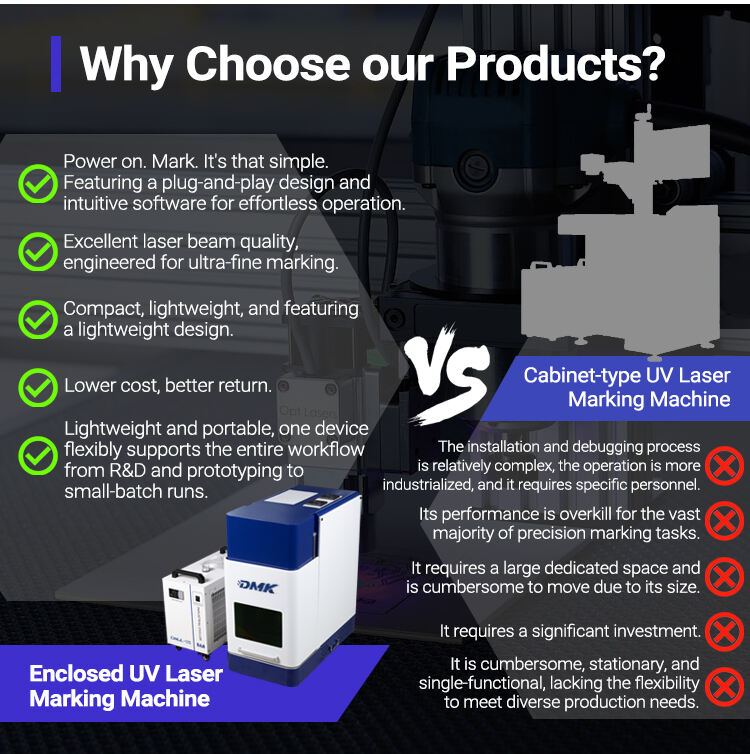

- Due to the extremely small focused spot size and minimal heat-affected zone (HAZ) of UV lasers, UV laser marking machines can perform ultra-fine marking and mark special materials. They are the preferred choice for customers with higher requirements for marking quality.

- Except for copper materials, UV lasers are compatible with a much wider range of materials.

- They not only feature excellent beam quality and smaller focused spots, enabling ultra-fine marking;

- They also have a broader application scope;

- The heat-affected zone is extremely small, avoiding thermal effects and material burning issues;

- They offer fast marking speed and high efficiency;

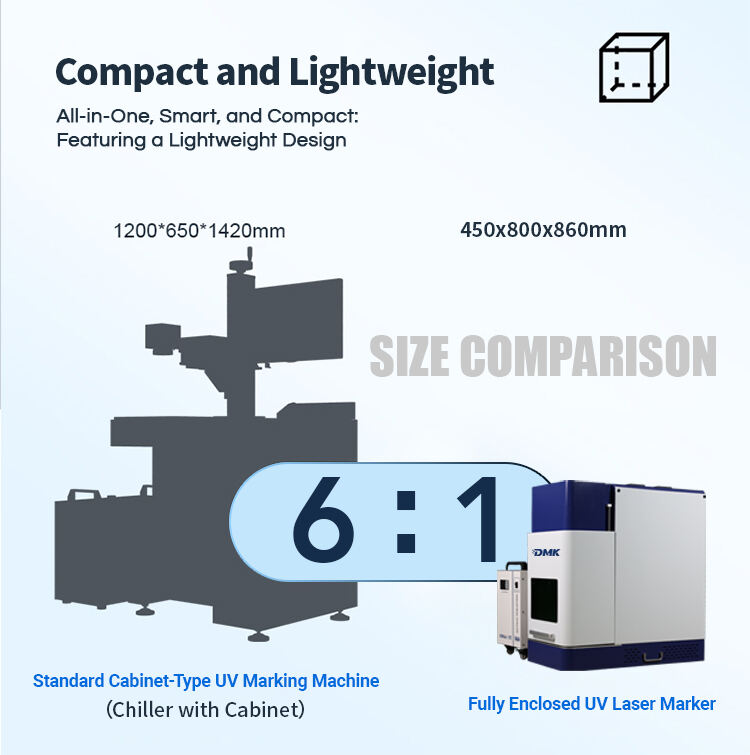

- They boast stable overall performance, compact size, and low power consumption.

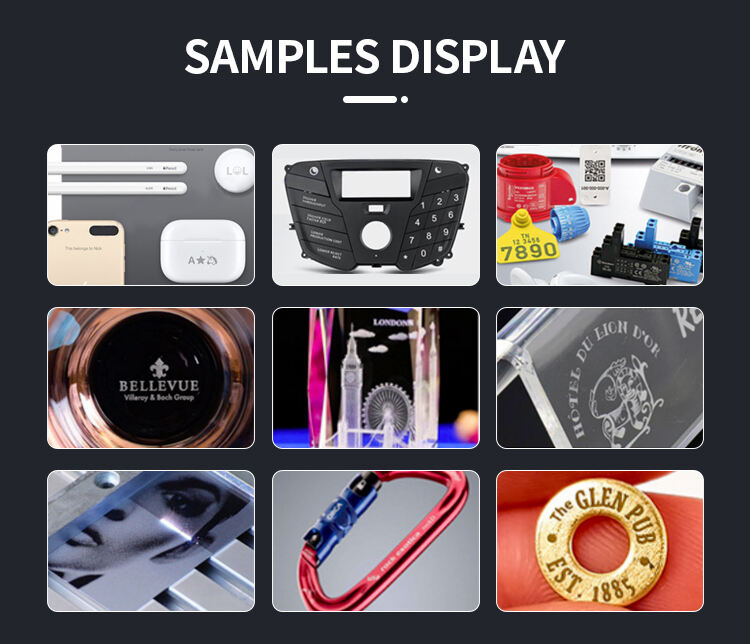

Applications

With its unique low-power laser beam, the UV laser marking machine is particularly suitable for high-end markets requiring ultra-fine processing. Its applications include:

- Marking on the surfaces of packaging bottles for cosmetics, pharmaceuticals, food, and other polymer materials-delivering fine, clear, and durable marks that outperform inkjet printing and are pollution-free;

- Marking and dicing of flexible PCB boards;

- Processing of microholes and blind holes on silicon wafers;

- QR code marking on LCD glass, surface drilling of glassware, marking on metal surface coatings;

- Marking on plastic buttons, electronic components, gifts, communication equipment, and building materials.

|

electronic component

|

|

glass and crystal products

|

|

metal products / food packaging

|

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR