200W Pulse Laser Cleaning | Marking | Cutting 3-in-1 Machine

Product Description

Looking for one machine that does it all? The KRD-C200W 3-in-1 Pulse Laser system combines laser cleaning, marking, and thin sheet cutting into a single compact design. Built with the trusted JPT MOPA fiber laser, it offers stable performance, long service life, and outstanding flexibility for industrial and workshop use. Whether you need to remove rust, engrave precise markings, or cut thin metal sheets, this system delivers results with speed and accuracy.

Why Choose This Machine?

✅ All-in-One Solution – Clean, mark, and cut with one machine.

✅ Powerful & Reliable – 200W JPT MOPA laser with uniform energy output.

✅ Easy to Use – Intuitive 7-inch touchscreen, 20 language options, and multiple operation modes.

✅ Lightweight Handheld Head – Comfortable grip, only 750g, with precision optics and durable build.

✅ Long Continuous Work – Designed for up to 16 hours of non-stop operation.

✅ Eco-Friendly – Non-contact cleaning, no chemicals, no damage to surfaces.

✅ Compact & Portable – Small footprint and easy to move, perfect for workshops or on-site service.

Specifications

| Item | Specification |

|---|---|

| Model | KRD-C200W |

| Laser Power | 200W |

| Max. Single Pulse Energy | 5 mJ |

| Laser Type | Fiber MOPA |

| Laser Brand | JPT |

| Wavelength | 1080 nm |

| Power Adjustment | 0–100% |

| Frequency Range | 1–3000 kHz |

| Pulse Width | 13–500 ns |

| Instability | <5% |

| Divergence Angle | ≤1.5 mrad |

| Cleaning Width | 1–100 mm |

| Focus Length | F=200 mm |

| Cleaning Modes | 9 modes |

| Continuous Operation | Up to 16 hrs |

| Noise Level | ≤60 dB |

| Fiber Cable | 5 m (standard) |

| Total Power Consumption | ≤1 kW |

| Voltage | AC110/220V ±10%, 50/60 Hz |

| Working Temperature | -10°C ~ 40°C |

| Cooling Method | Air-cooled |

| Net Weight | 20 kg |

| Machine Size | 450 × 170 × 360 mm |

| Packed Size/Weight | 490 × 210 × 480 mm, 28 kg |

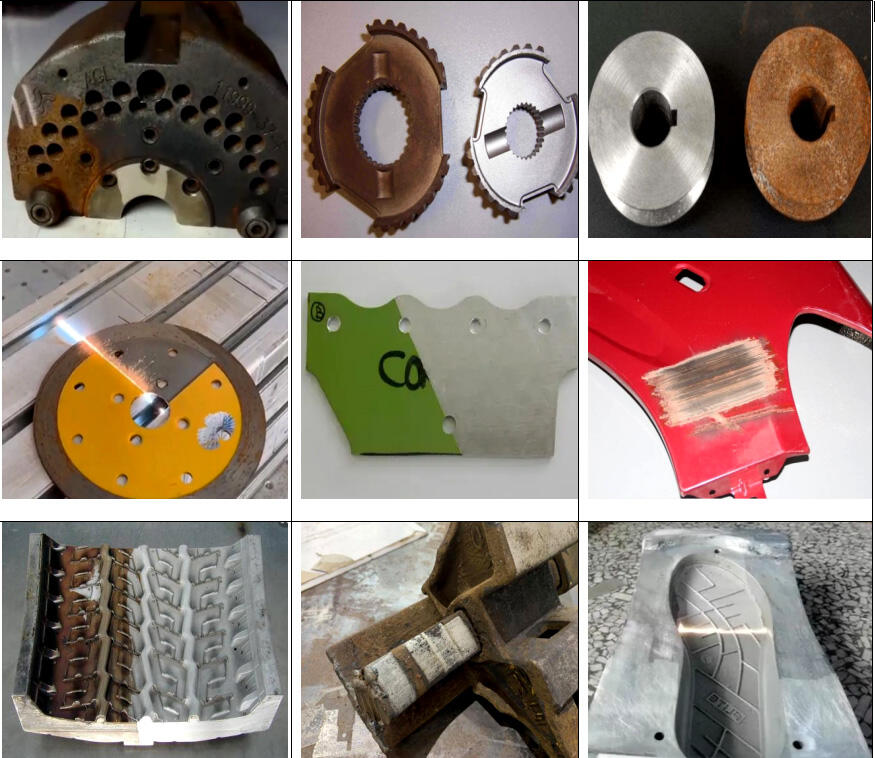

Ideal Applications

Rust, oil, paint, and coating removal

Precision metal marking & engraving

Thin sheet cutting for stainless steel, carbon steel, etc.

Surface treatment before welding or bonding

Mold cleaning and restoration work

Industrial maintenance and repair

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR