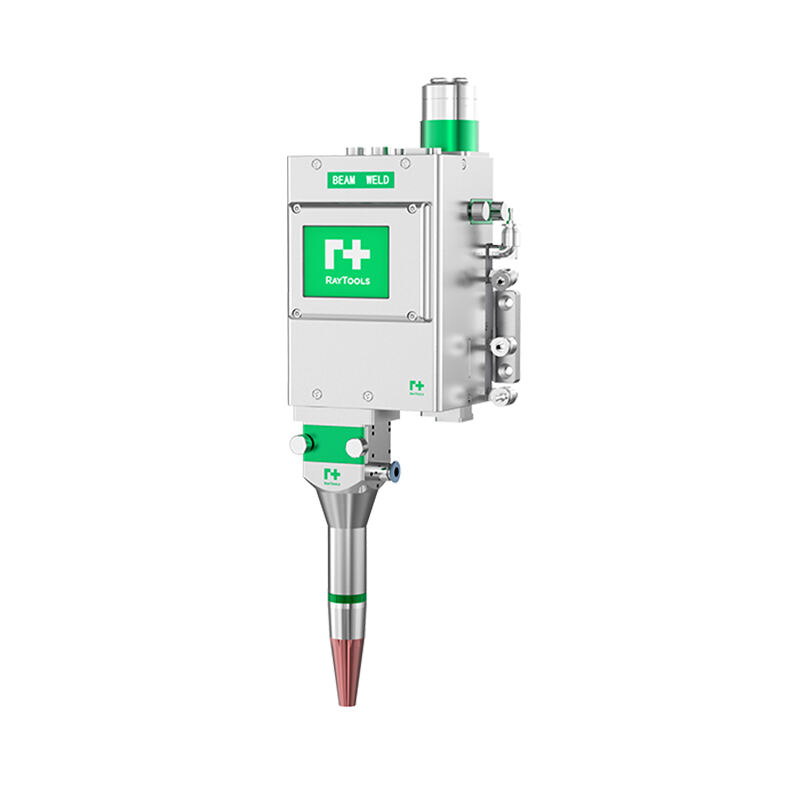

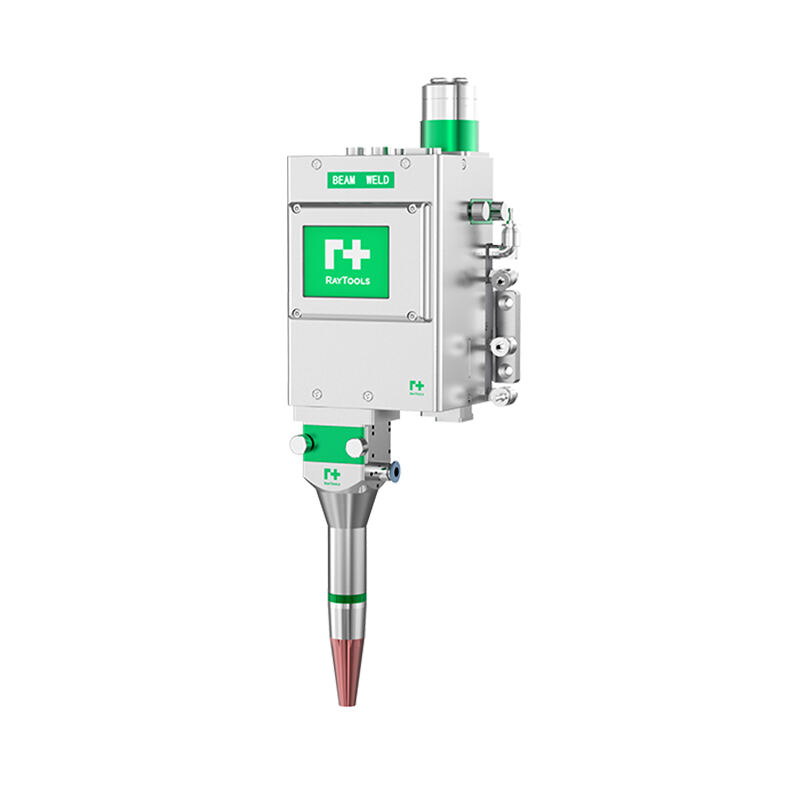

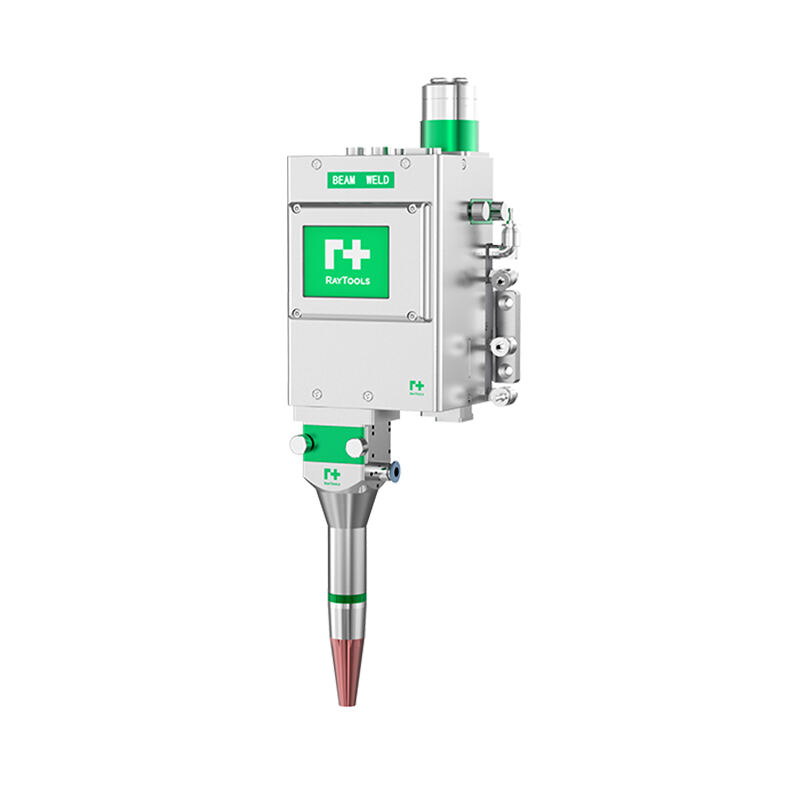

2000W Raytools BF02S Oscillating Laser Welding Head

Product Description

The BF02S Oscillating Laser Welding Head is a compact, lightweight solution engineered for high-precision welding applications with laser power below 3000W. Featuring a dual-motor oscillation system, it supports multiple oscillation patterns to enhance adaptability across a wide range of materials and joint types.

Its all-in-one drive and control design simplifies integration, while the built-in high-definition CCD camera enables real-time monitoring for improved welding accuracy. Compared to traditional laser welding heads, the BF02S delivers superior stability, consistency, and aesthetic weld quality.

By widening the weld seam through controlled oscillation, it compensates for gaps between workpieces and allows for better welds on dissimilar materials and complex geometries. With adjustable oscillation patterns, amplitudes, and frequencies, the BF02S is an ideal choice for achieving efficient, high-quality welds in demanding industrial environments.

Parameters

| Model | BF02K-mini |

| Total Power Capacity | 2000W |

| Collimation focal length (MM) | 100 |

| Focus focal length (mM) | 200/250/300 |

| Scanning range | X:0~5mm;Y:0~5mm |

| Maximum frequency (Hz) | 500 |

| Aperture (mM) | 14 |

| Interface type | QBH |

| Weight | ~2.0kg |

| Welding shielding gas | 15-25L/min |

| Swing range | 0-5mm |

Advantages

|

Innovative Design Lightweight and compact structure, weighing only 2KG, significantly reduces the load on robotic arms. Simple operation with an intuitive interface. |

|

|

Multiple Oscillation Patterns Offers 8 different welding patterns to meet various process requirements. |

|

Optimized Internal Design Features a sealed internal design that is highly dustproof and debris-resistant, ensuring stable and reliable operation. |

|

|

Stable and Convenient Operation Integrated drive and control system with strong anti-interference capabilities and simple external wiring. |

|

Strong Compatibility Equipped with a built-in display for control, supporting offline and PC-controlled operation modes. |

|

|

Process Advantages Achieves low porosity, high mechanical performance, and high-quality weld surfaces. |

|

Integrated Motor Driver The built-in motor driver prevents interference caused by long signal lines when using external drivers, resulting in more stable operation. |

|

|

Simple Control Integration Control is easy via IO for start/stop and program selection, facilitating seamless integration into existing systems. |

|

Fully Enclosed CCD Camera The mechanical design of the fully enclosed CCD camera protects the optical components from dust contamination. |

|

|

Water-Cooling System The entire unit features a water-cooling design, making water connection straightforward. |

Applications

The BF02S is widely used in industries such as automotive manufacturing, aerospace, and metal fabrication. Its ability to handle various materials and complex geometries makes it suitable for applications like:

- Welding of thin sheets and complex assemblies

- Joining dissimilar materials, such as aluminum to steel

- High-speed production lines requiring efficient and reliable welding processes

This versatility ensures that the BF02S meets the diverse needs of modern manufacturing environments, providing exceptional welding quality and efficiency.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR