150W High-Precision Laser Micro-Hole Machine 0.02mm Aperture Multi-industry Drilling

Product Description

The YCGJM6060ZX-WK-150W high-precision laser micro-drilling machine utilizes an internationally advanced, specially designed fiber laser, boasting excellent beam quality, high photoelectric conversion efficiency, and requiring minimal maintenance with low operating costs.

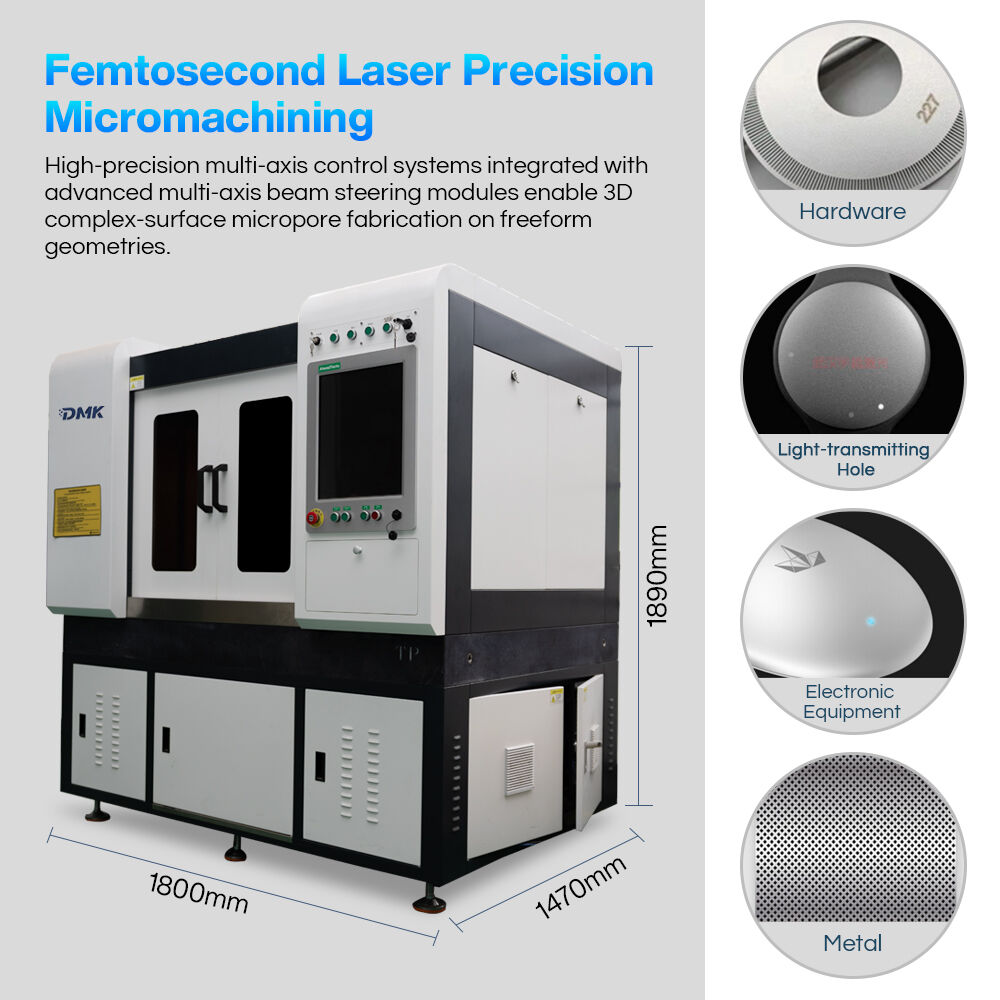

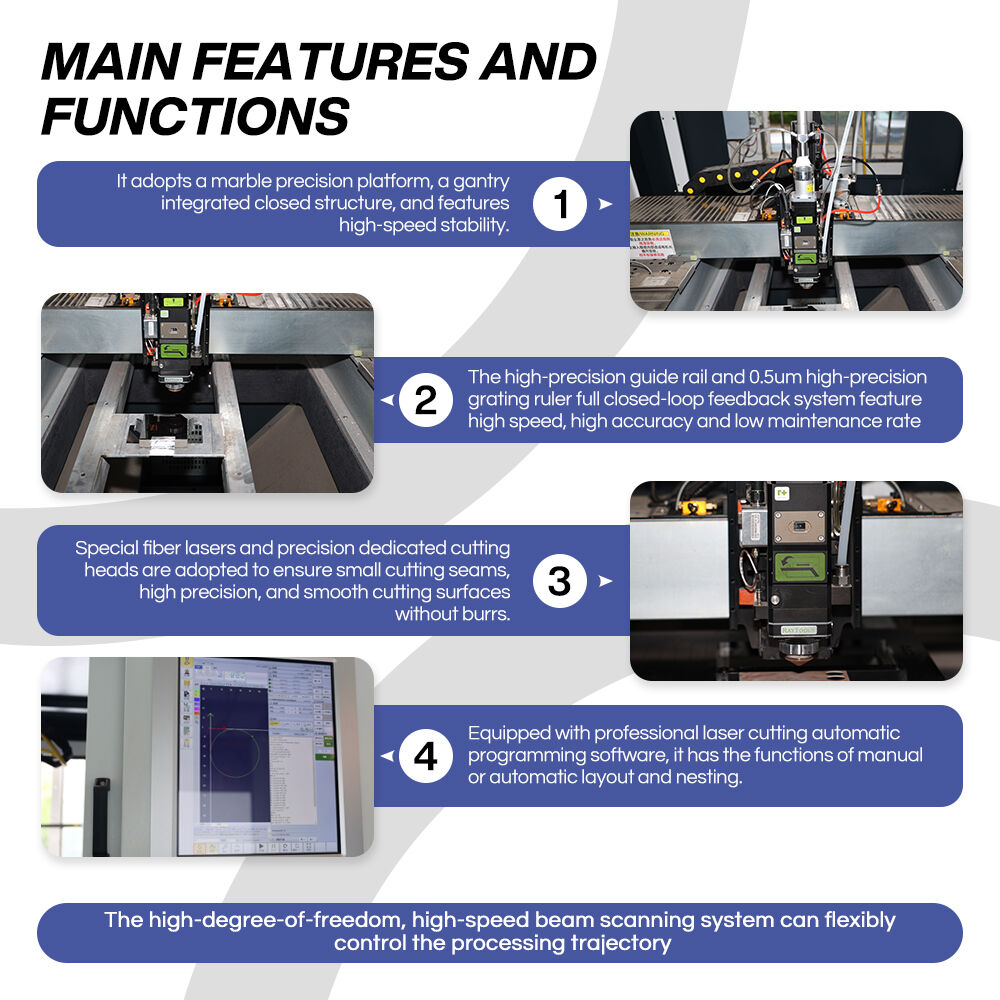

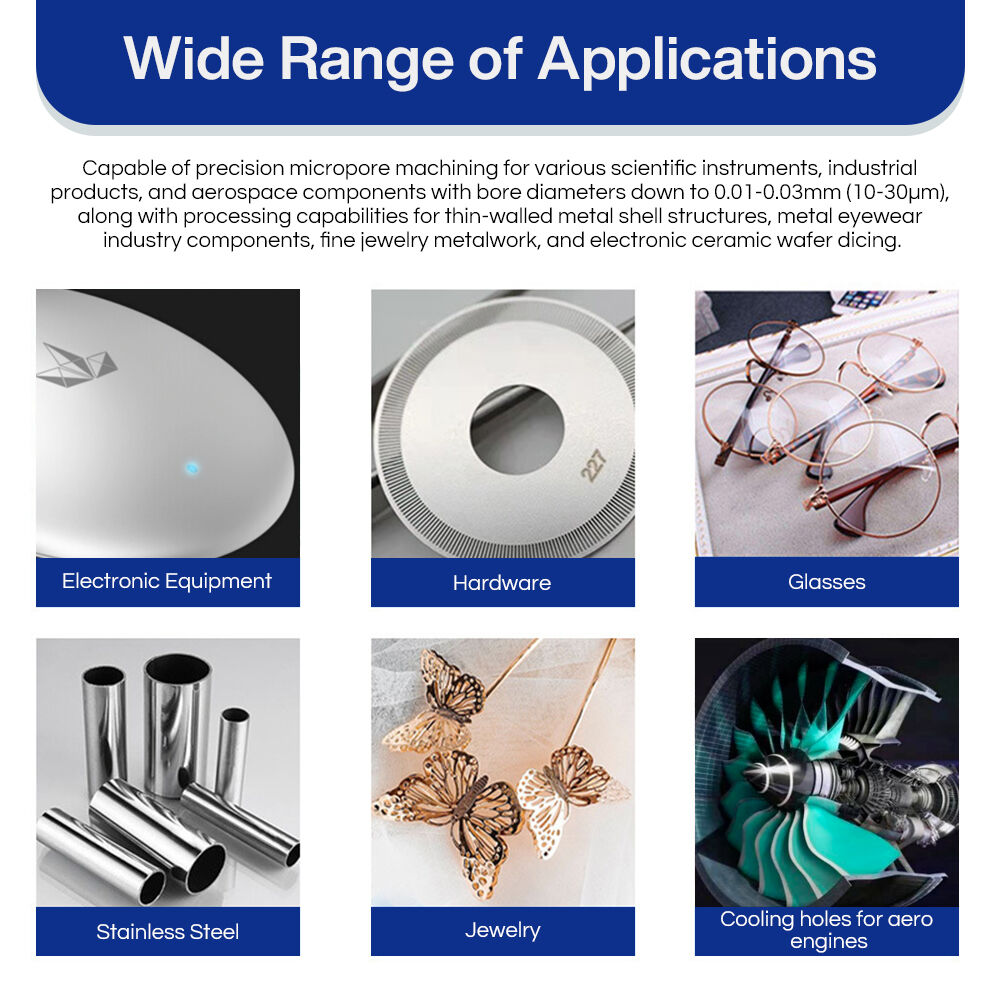

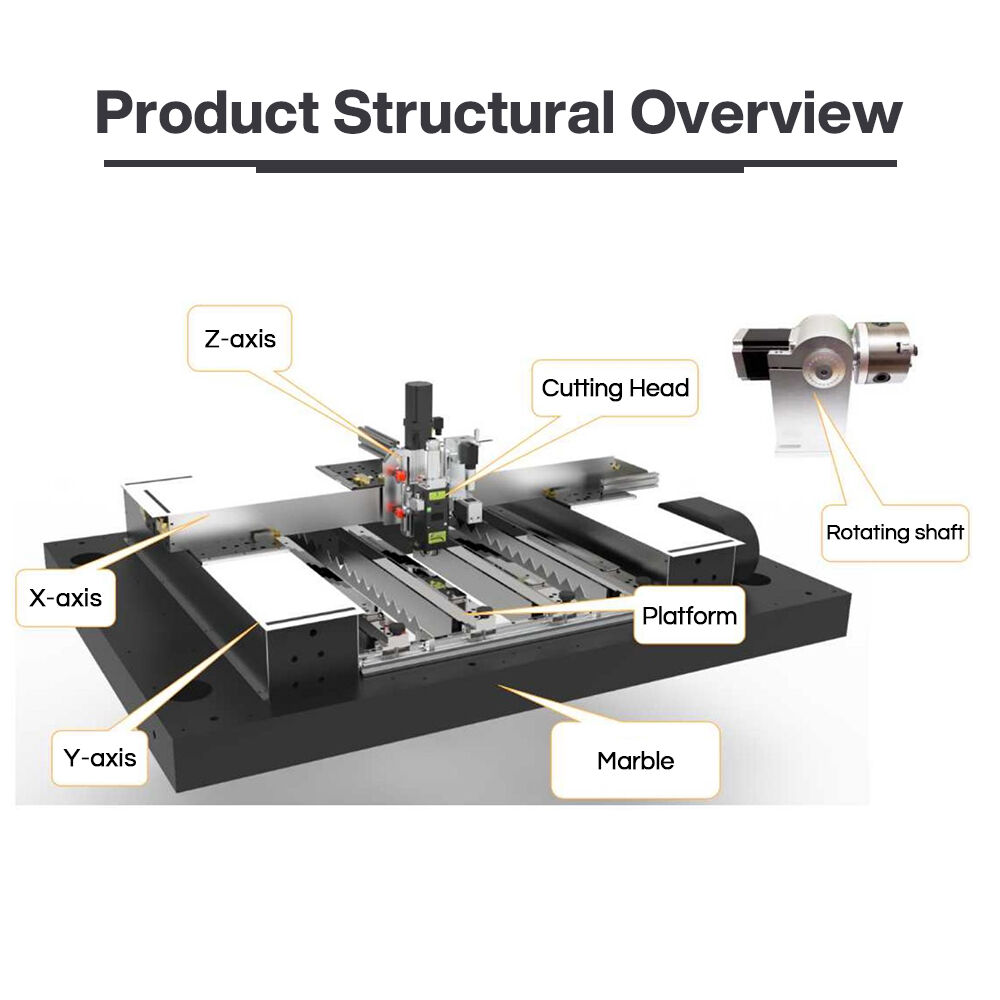

The equipment is specifically designed for high-speed, high-precision cutting and micro-drilling of metal materials, capable of processing various materials including stainless steel, carbon steel, tungsten steel, and aluminum alloys. It can achieve a minimum hole diameter of 0.02-0.03mm, reaching an advanced level in the domestic market. Equipped with a precision marble platform and a gantry-type integrated enclosed structure, along with imported linear motors, high-precision guide rails, and a 0.5um grating ruler full-closed-loop feedback system, it achieves a positioning accuracy of ±0.01mm and a repeatability of ±5um, ensuring processing stability and precision.

The non-contact processing minimizes thermal effects, resulting in no mechanical deformation of the workpiece, small kerf width, and a smooth, burr-free surface. It features a 17-inch color touchscreen and professional automatic programming software, supporting DXF/DWG file import and automatic nesting. The capacitive sensing cutting head automatically adjusts the cutting height, making it suitable for micro-hole processing needs in various industries, including 3C wearable devices, atomizing sheets, metal filter screens, and military products.

Product Parameters

| Parameter Category | Specific Parameters |

|---|---|

| Core Laser Parameters | - Laser Wavelength: 1060-1080nm - Laser Power: 150W - Laser Frequency: 1-5000HZ (Adjustable) - Minimum Hole Diameter: ≥0.02-0.03mm (Material Thickness Dependent) |

| Processing Accuracy and Range Parameters | - Effective Cutting Area: 600×600mm - Positioning Accuracy: ±0.01mm - X/Y Axis Repeat Positioning Accuracy: ±5um - Drilling Accuracy: ±0.01mm - Processing Material Thickness: 0.1-1mm |

| Motion and Speed Parameters | - Transmission Method: Imported Linear Motor + 0.5um Grating Ruler - Processing Speed: 0-500mm/s - Maximum Moving Speed: 60m/min |

| Shape and Energy Consumption Parameters | - Overall Machine Power (Excluding Fan): ≦5KW - Total Machine Weight: Approximately 1600KG - External Dimensions: 1800×1470×1890mm (Subject to Actual Product) |

| Software and Interface Parameters | - Compatible File Formats: DXF, DWG - Operation Interface: 17-inch Color LCD Touch Screen - Interfaces: USB Interface, Ethernet Interface |

Other Details

1、Equipment Configuration and Features

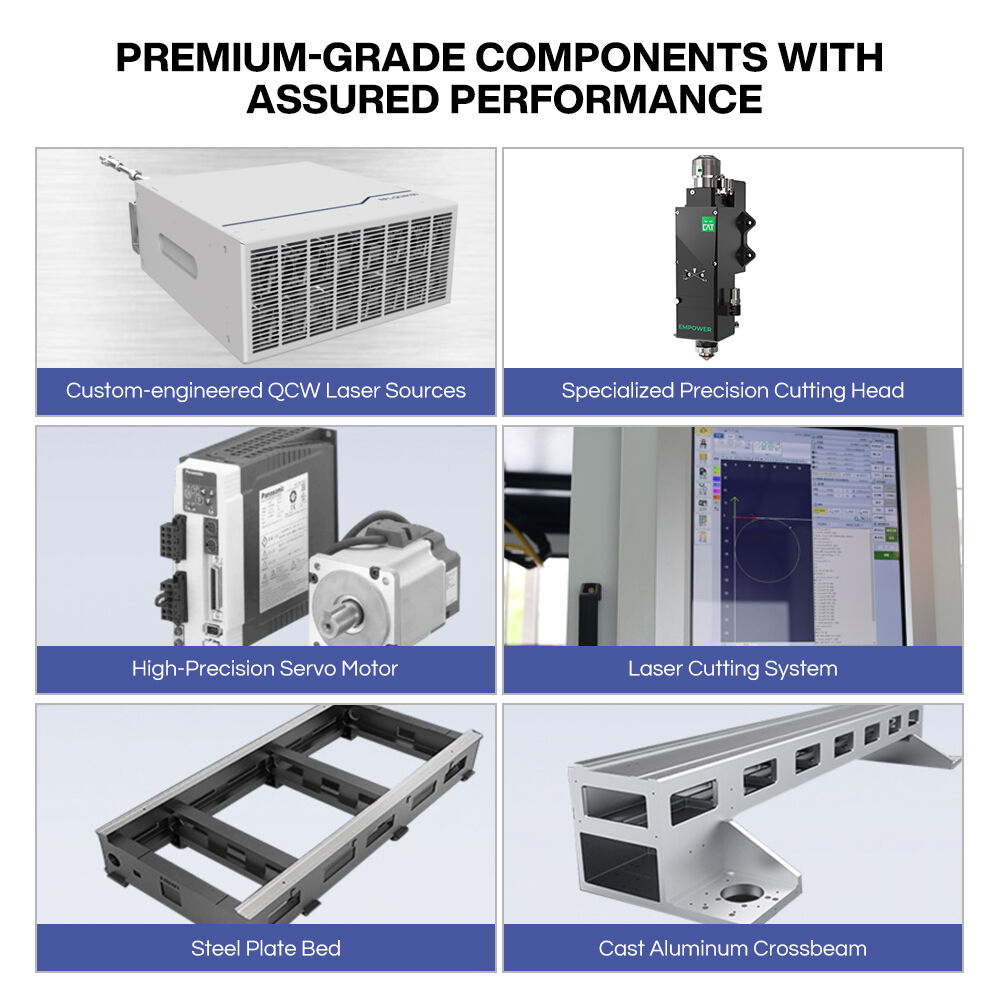

- Core Configuration: QCW customized fiber laser, Switzerland Raytools special precision cutting head, US AheadTechs bus-type closed-loop control system, Switzerland RT linear motor + marble table, Japan THK precision guide rail, etc.

- Core Features: Capacitive sensing cutting head automatically adapts to material flatness; non-contact processing without mechanical deformation; automatic programming software supports nesting; multi-interface design for convenient file transmission; low operating cost, with consumables cost only 0.42 yuan/hour.

2、Operating Costs and Environmental Requirements

| Operating Costs | Environmental Requirements |

|---|---|

| - Electricity Cost: 4.2 yuan/hour - Auxiliary Gas Cost: Liquid oxygen 9 yuan/hour, liquid nitrogen 26.7 yuan/hour, air 5 yuan/hour - Consumable Cost: 0.42 yuan/hour | - Power Supply: 220V 50Hz, recommended 30KVA regulated power supply, voltage stability ±5% - Room Temperature: 10℃~30℃ (air conditioning required) - Air Humidity: ≤75% - Gas Purity: Oxygen ≥99.95%, Nitrogen ≥99.99% |

3、Service and After-sales

- Pre-sales Service: Provide process plans, technical consultation, sample testing and on-site inspection reception.

- In-sales Service: Free delivery, installation and commissioning (completed in 1-2 days), provide 3-5 days technical training.

- After-sales Service: 1-year free warranty for the whole machine, lifelong maintenance; 24-hour customer response, lifelong free software and hardware upgrades.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR