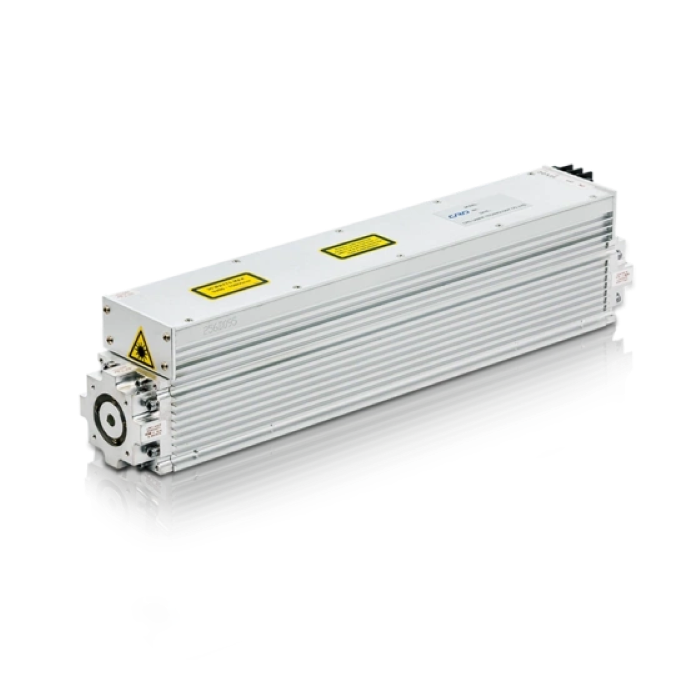

12W-CR12 Radio Frequency CO₂ Laser

Product Description

The CR12 Type Radio Frequency CO₂ Laser provides an output power of 12W. It adopts a design featuring a sealed waveguide and an integrated radio frequency power supply, boasting high product reliability and the capability to operate continuously for 7×24 hours in harsh industrial environments over the long term.

The CR12 Type Laser offers excellent beam quality and power stability. Its laser wavelength ranges from 9.3 to 10.6μm, and it can be configured with either air cooling or water cooling systems. These characteristics make it the preferred laser for high-performance laser marking and engraving systems, while requiring only low operating and maintenance costs.

The CR12 Type Laser is an ideal choice for laser processing of various materials, including paper, plastic, wood, thin leather, and more.

Key Features

I. Powerful Power and Stable Structure

With an output power of 12W, it adopts a design of sealed waveguide and integrated radio frequency power supply, featuring high reliability. It can achieve long-term continuous operation 24 hours a day, 7 days a week in harsh industrial environments, reducing the impact of production caused by equipment downtime.

2. Excellent Performance and Flexible Cooling

It has outstanding beam quality and power stability, with a laser wavelength range of 9.3-10.6μm. Moreover, it supports two cooling methods: air cooling and water cooling, which can adapt to the needs of different working conditions.

3. Cost-Effective Advantages

While ensuring high performance, it has low operation and maintenance costs, and no complex maintenance procedures are required, reducing the comprehensive investment of enterprises in long-term use.

Technical Parameters

Model |

CR12 |

CR12i |

Wavelength (μm) |

10.55 - 10.63 μm |

9.24 - 9.35 μm |

Output Power (W)① |

> 12 W |

> 12 W |

Power Stability②③ |

< ±6% |

< ±6% |

Beam Quality (M²) |

< 1.2 |

< 1.2 |

Beam Ellipticity |

< 1.2 |

< 1.2 |

Beam Diameter (1/e²) |

3.5 mm |

3.5 mm |

Beam Divergence Angle |

< 4 (mrad, full angle) |

< 4 (mrad, full angle) |

Height of Light Exit Port |

32.5 mm |

32.5 mm |

Polarization (Linear Polarization, Parallel to Width) |

> 50:1 |

> 50:1 |

Modulation Frequency |

0 - 20 kHz |

0 - 20 kHz |

Duty Cycle |

0 - 100% |

0 - 100% |

Weight |

4.1 kg (Air - cooled) / 4.3 kg (Water - cooled) |

4.1 kg (Air - cooled) / 4.3 kg (Water - cooled) |

Dimensions (Length × Width × Height) |

430 × 71 × 100 mm (Air - cooled) / 460 × 71 × 100 mm (Water - cooled) |

430 × 71 × 100 mm (Air - cooled) / 460 × 71 × 100 mm (Water - cooled) |

Heat Dissipation Method |

Air - cooling / Water - cooling |

Air - cooling / Water - cooling |

Thermal Load |

< 210 W |

< 210 W |

Power Requirements | ||

Input Voltage |

30 VDC |

30 VDC |

Input Current |

7 A |

7 A |

Environmental Conditions | ||

Maximum Shell Temperature |

< 60 °C |

< 60 °C |

Ambient Temperature |

5 - 40 °C |

5 - 40 °C |

Altitude |

< 2000 m |

< 2000 m |

Humidity |

< 95%, No Condensation |

< 95%, No Condensation |

Shipping and Storage Environment |

-10 - 60 °C, No Condensation |

-10 - 60 °C, No Condensation |

Cooling Water Requirements | ||

Flow Rate |

4 L / min |

4 L / min |

Temperature |

20 - 25 °C |

20 - 25 °C |

Maximum Pressure |

0.6 MPa |

0.6 MPa |

Applications

1. Laser Marking:Relying on its stable performance, it is suitable for materials such as paper, plastic and wood, meeting the marking needs in fields like packaging and electronic components.

2. Laser Engraving:With precise laser output, it is applicable to the engraving processing of materials such as thin leather and handicrafts, contributing to fine manufacturing.

3. Multi-Material Processing:It can process non-metallic materials including paper, plastic, wood and thin leather, adapting to the diverse needs of small enterprises and processing workshops.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR