3-Axis 100/200/300 Automated Laser Cleaning Machine

Product Description

Precision Automation Meets High-Efficiency Laser Cleaning

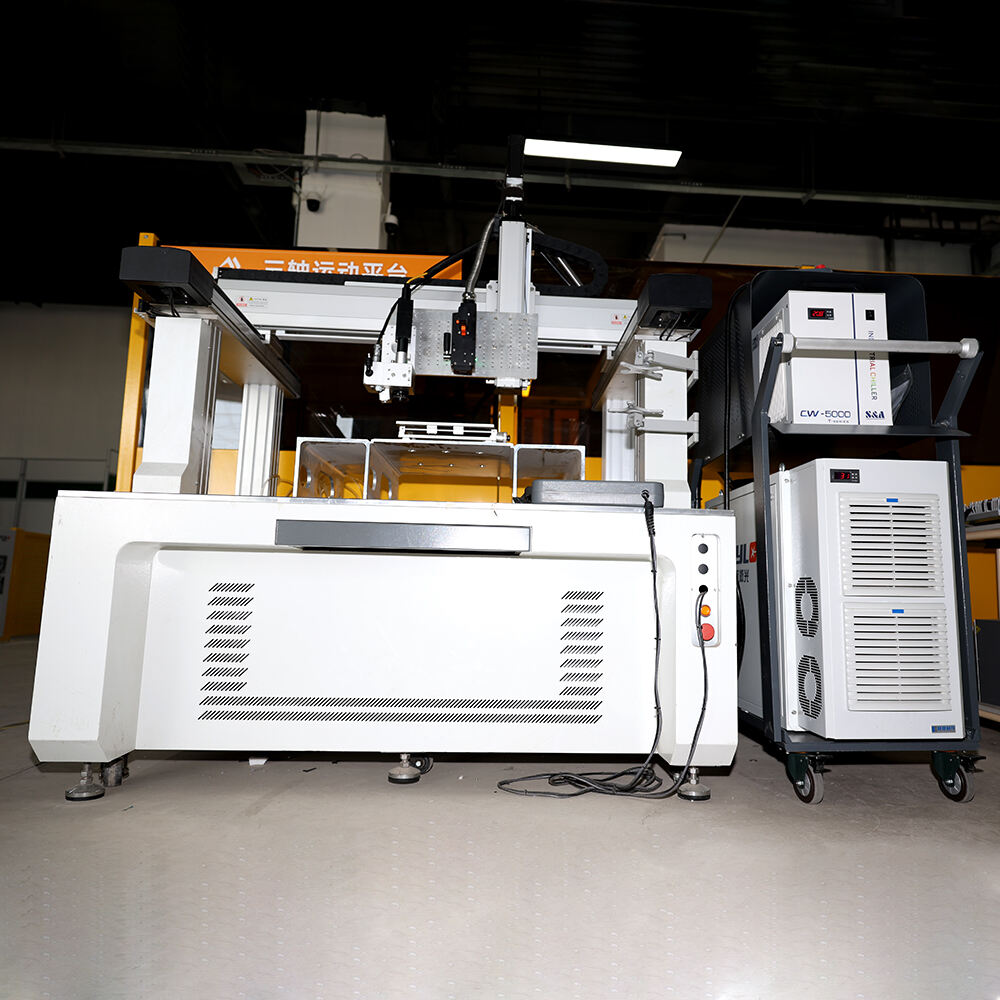

The DMK-SPM-100/200/300 3-Axis model is DeMark’s advanced automated laser cleaning solution, integrating a high-precision XYZ motion system with a powerful pulsed laser source. Engineered for consistent, high-speed, and programmable cleaning operations, this system is ideal for industrial users seeking efficiency, stability, and minimal manual intervention.

Key Features

Fully Automated 3-Axis Control: Built-in XYZ motion platform enables precise path programming and unmanned operation.

Non-Contact Cleaning: No surface abrasion or material damage—safe for delicate substrates.

Eco-Friendly Technology: No need for chemical solvents or blasting media; produces no secondary pollution.

High Flexibility: Supports customized scanning paths, cleaning parameters, and fixture integration.

Low Cost of Ownership: No consumables; only electrical energy required.

|

|

Technical Specifications

Product Model |

SKYLC-SPM-100/200/300 |

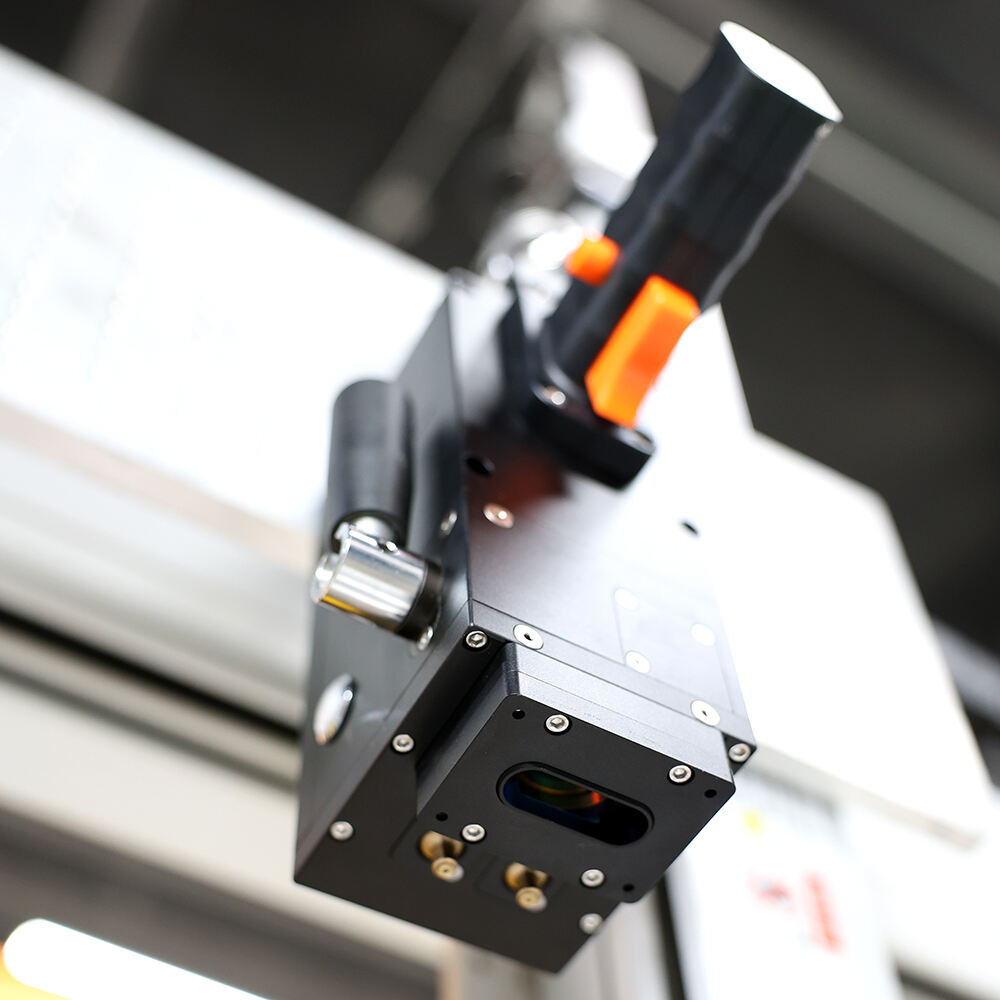

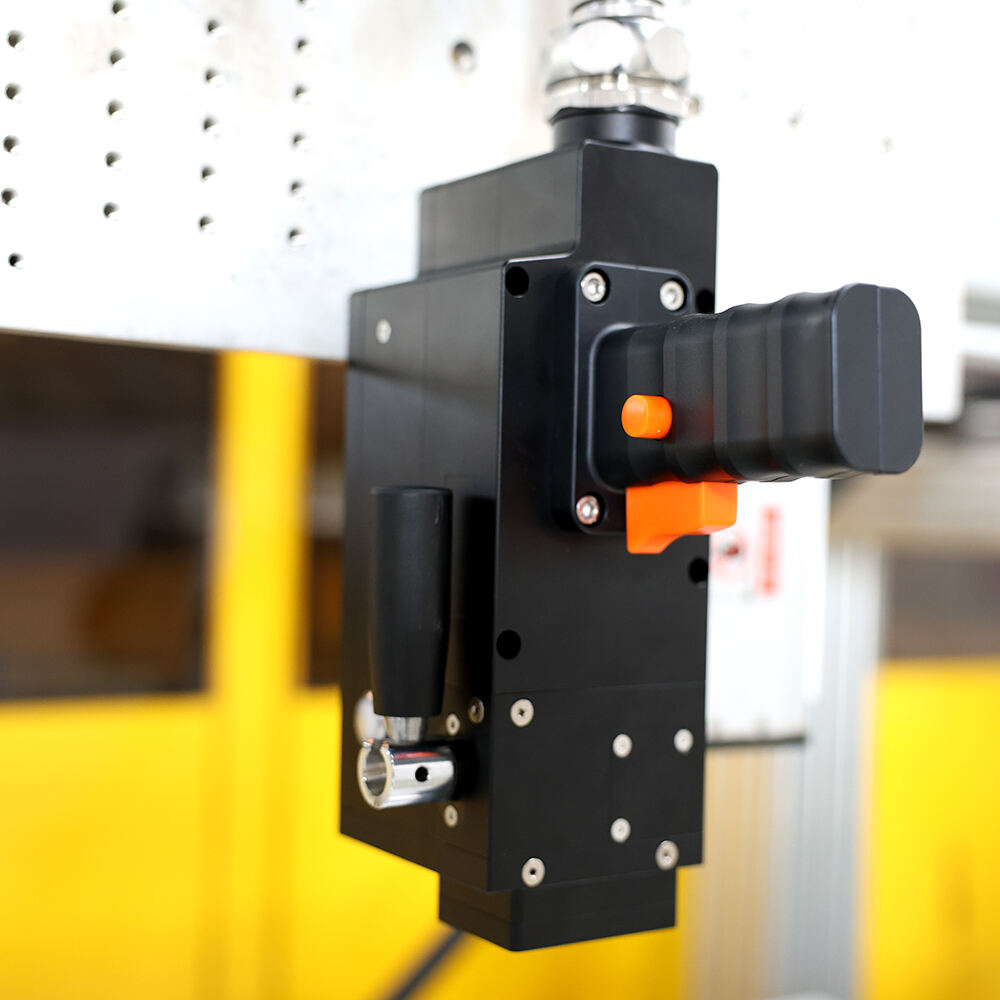

Cleaning head model |

Type A |

Laser average power |

100W/200W/300W |

Power adjustable range |

10%~100% |

Polarization direction |

Arbitrary |

Laser line width |

Width:5mm ~ 100mm adjustable |

Fiber length |

5m |

Minimum Fiber Bend Radius |

150mm |

Cooling mode |

Water cooling + Air condition |

Guided Laser Function |

Have |

Anti-high-reflection function |

Have |

Field lens model |

F160/F210/F254 Optimize the model according to the actual working conditions |

※The above parameters are for reference only, please refer to the actual | |

SKYLC-SPM-100/200/300 general property parameters

Product model |

SKYLC-SPM-100 |

SKYLC-SPM-200/300 |

Chassis Size |

L1053mm×W400mm×H700mm (please refer to the actual) |

L1075mm×W735mm×H1402mm(Integrated type) L1030mm×W400mm×H700mm (Split main unit) L560mm×W290mm×H445mm (Split water cooling machine) |

Net weight of main unit |

80kg |

120kg(Integrated type) 85kg(Split host) 20kg(Split water cooling machine) |

Net weight of cleaning head |

2.8kg |

|

Operate mode |

Automated / Handheld |

|

Supply Voltage |

Single phase three-wire system AC 220±10%V |

|

Utility frequency |

50Hz |

|

Work temperature |

0℃ ~ 40℃ |

|

Storage temperature range |

-10℃ ~ 60℃ |

|

Power consumption @25℃ |

<1000w |

<3200w |

※The above parameters are for reference only, please refer to the actual | ||

|

|

Applications

Perfect for applications requiring repeatable, high-precision cleaning:

Automated removal of rust, paint, grease, and oxide layers

Pre-treatment before welding, coating, or adhesive bonding

Post-welding cleaning in production lines

Localized cleaning of high-value components or molds

Applicable Industries: Aerospace, Rail Transit, Automotive, Precision Manufacturing, Mold Repair, Additive Manufacturing, and Semiconductors.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR