Composite materials are all around us, even if we don’t always notice them. In simple terms, a composite is made by combining two different materials to create a product with improved properties compared to the individual components. This idea ...

Contact Us

Composite materials are all around us, even if we don’t always notice them. In simple terms, a composite is made by combining two different materials to create a product with improved properties compared to the individual components. This idea isn’t new—examples range from reinforced concrete, where steel bars strengthen concrete, to sandwich panels, which use a foam core between aluminum sheets for lightweight stiffness.

While composites can be made from many different material combinations, one of the most exciting areas of development has been in fiber-reinforced polymers—and, more specifically, Continuous Fiber Reinforced Thermoplastics (CFR Thermoplastics). In these materials, continuous fibers—sometimes called endless fibers—provide exceptional reinforcement, making them ideal for high-load, high-performance applications.

The modern composites industry began with the pairing of fibers and thermosetting polymers, often referred to simply as thermosets. A thermoset starts as a liquid or soft solid resin that can be combined with fibers and molded into a specific shape. Once cured, it hardens irreversibly.

This irreversible property has both benefits and drawbacks:

Advantages – The low viscosity of thermoset resins makes them easy to impregnate into fibers, producing strong, stable shapes.

Disadvantages – Once cured, thermosets cannot be reshaped or reprocessed. Recycling them is difficult, often limited to burning in incinerators, which yields minimal energy and can release harmful fumes.

By comparison, metals and thermoplastics offer better recyclability, which has become an increasingly important factor in sustainable manufacturing. This recyclability challenge is one of the main limitations of thermoset composites in a circular economy.

Unlike thermosets, thermoplastics soften when heated and harden when cooled—without undergoing a permanent chemical change. This means they can be reshaped and reused, giving them a significant sustainability advantage.

However, developing thermoplastic composites was not straightforward. Thermoplastics have a higher viscosity than thermoset resins, making it more difficult to fully impregnate fibers. Advances in manufacturing technology have overcome these challenges, leading to the production of unidirectional (UD) tape—thin strips of composite material in which fibers are perfectly aligned in a single direction.

By layering these tapes at different angles, engineers can tailor strength in specific directions or create quasi-isotropic behavior, where the material has balanced strength in all directions. This flexibility makes thermoplastic composites highly adaptable to different performance requirements.

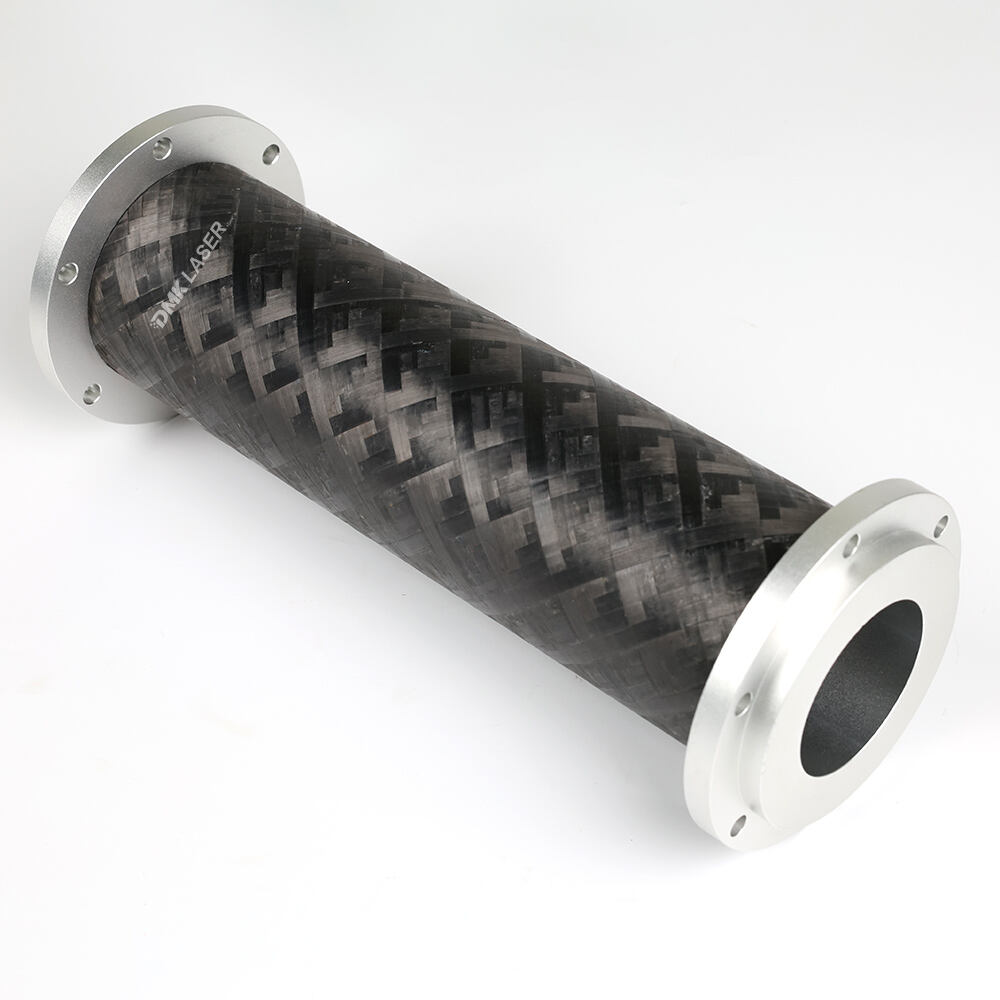

CFR Thermoplastics—short for Continuous Fiber Reinforced Thermoplastics—are made by processing UD tape or sheet through methods such as thermoforming, tape laying, or tape winding. The continuous fibers provide maximum strength along their length, making CFR Thermoplastics especially valuable in demanding, high-load applications.

One of their key advantages is their ability to withstand high operating temperatures. For example:

PEEK (Polyether Ether Ketone), PAEK, and PEKK are high-performance thermoplastic polymers that retain mechanical strength and stability in extreme heat.

Thermoplastics soften above their glass transition temperature (Tg), allowing them to be formed or reshaped much like metals. This process can be done locally—only heating and reshaping the part of the product that needs modification—making them highly versatile in manufacturing.

Equally important, CFR Thermoplastics are fully recyclable. Scrap material can be reprocessed, reducing waste and making these composites an excellent fit for the circular economy.

High Strength-to-Weight Ratio – Continuous fibers deliver maximum reinforcement with minimal added weight.

Heat Resistance – High-performance thermoplastics maintain structural integrity under elevated temperatures.

Formability – Can be reshaped with heat, enabling design flexibility and repairability.

Recyclability – Supports sustainable manufacturing and waste reduction.

Design Optimization – Layering tapes at strategic angles allows for tailored mechanical performance.

Final Thoughts

CFR Thermoplastics represent a significant step forward in composite materials technology. By combining the strength of continuous fibers with the versatility and recyclability of thermoplastics, they offer a sustainable, high-performance alternative to traditional thermoset composites. As industries continue to prioritize both performance and environmental responsibility, CFR Thermoplastics are poised to play a major role in the next generation of engineered products.