Metal powder is one of the most critical components in the additive manufacturing (AM) industry, forming the foundation for 3D printed metal parts. At the 2013 World 3D Printing Technology Industry Conference, experts defined 3D printing metal powder...

Contact Us

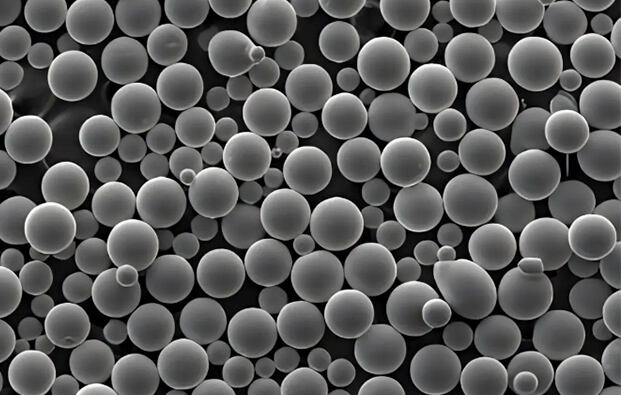

Metal powder is one of the most critical components in the additive manufacturing (AM) industry, forming the foundation for 3D printed metal parts. At the 2013 World 3D Printing Technology Industry Conference, experts defined 3D printing metal powder as a collection of metallic particles with diameters under 1 mm, including pure metals, metal alloys, and refractory compounds with metallic properties.

Currently available metal powders for 3D printing include cobalt-chromium alloys, stainless steel, tool steels, bronze alloys, titanium alloys, and nickel-aluminum alloys. To meet the stringent demands of AM processes, metal powders must exhibit:

Fine particle size

Narrow size distribution

High sphericity

Excellent flowability

High tap and bulk density

Depending on the intended application and downstream forming process, different powder production techniques are used. These fall into two broad categories:

Physicochemical methods

Mechanical methods

In the powder metallurgy industry, electrolysis, reduction, and atomization are common, though not all are suitable for producing alloy powders. In additive manufacturing, the primary focus is on titanium alloys, superalloys, cobalt-chromium, high-strength steels, and tool steels. To meet performance standards, powders must maintain:

Low oxygen and nitrogen content

High sphericity

Narrow particle size range

High bulk density

Currently, the four most prominent methods for producing spherical metal powders for AM are:

Plasma Rotating Electrode Process (PREP)

Plasma Atomization (PA)

Gas Atomization (GA)

Plasma Spheroidization (PS)

Principle:

Metal rods (electrodes) are rotated at high speeds while the tip is melted by a plasma arc. The molten material is thrown off by centrifugal force, forming fine droplets that solidify into nearly spherical powder under inert gas conditions.

Key Features:

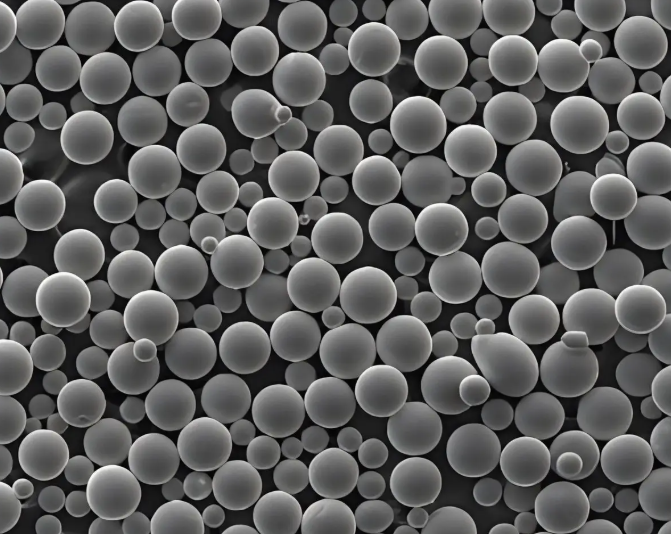

Produces clean, highly spherical powder

Excellent flowability and surface quality

Narrow particle size distribution

Limitations:

Lower yield of fine powders (<45 μm)

High equipment requirements (rotational speed, containment)

Higher cost for fine powders

Application:

Best suited for producing spherical alloy powders such as titanium and high-temperature alloys. The larger particle sizes are often used in Laser Engineered Net Shaping (LENS) or Directed Energy Deposition (DED) processes.

Principle:

A metal wire is fed into a high-temperature plasma zone, where it is melted or vaporized and broken into microdroplets by the plasma’s kinetic energy. These droplets cool and solidify into fine powders as they descend through an inert gas chamber.

Key Features:

High yield of ultra-fine powder (<45 μm)

Minimal hollow particles or gas entrapment

Excellent for high-melting-point alloys

Limitations:

Requires wire feedstock, limiting alloy flexibility

Higher production costs due to wire processing

Presence of some satellite powder

Application:

Ideal for additive manufacturing applications requiring high-purity, fine-grained powders. Well-suited for titanium alloys used in selective laser melting (SLM) and electron beam melting (EBM).

Types:

VIGA (Vacuum Induction Gas Atomization)

Uses a crucible to melt metal under vacuum. The molten stream is broken into droplets by high-pressure inert gas jets.

EIGA (Electrode Induction-melting Inert Gas Atomization)

Melts a rotating metal electrode using induction coils, eliminating the need for a crucible and reducing contamination risk.

Key Features:

High efficiency and cost-effectiveness

Wide alloy compatibility (steel, nickel, cobalt, aluminum, copper)

Controllable particle size

Limitations:

Sphericity lower than plasma-based methods

Higher satellite and hollow powder content

Air entrapment makes it less suitable for EBM or Hot Isostatic Pressing (HIP)

Application:

Widely used for producing powders for SLM and DED processes. Continuous improvements, such as ultrasonic and laminar-flow gas atomization, have enhanced powder quality for AM.

Principle:

Irregular metal powders are fed into a radio-frequency (RF) plasma torch. The particles are heated to near or above their melting point and then rapidly cooled, forming spherical particles under surface tension.

Key Features:

High sphericity and smooth surfaces

Good flowability

Suitable for refractory metals (tantalum, tungsten, niobium, molybdenum)

Limitations:

Long heating cycles

Elevated oxygen content due to increased surface area

Loss of volatile alloy elements during melting

Application:

Primarily used to reprocess non-spherical powders into spherical ones. Also valuable for reclaiming used or recycled powders.

| Method | Particle Shape | Powder Size | Fine Powder Yield (<45 μm) | Cost | Notes |

|---|---|---|---|---|---|

| PREP | Highly spherical | Medium to coarse | Low | High | Ideal for clean, large spherical powders |

| PA | Near-spherical | Fine | Very high | High | Best for ultra-fine powders |

| GA | Spherical | Broad range | High | Low | Widely adopted in industry |

| PS | Spherical (from irregular) | Variable | Dependent on feedstock | Medium | Used for powder recycling or refinement |

Globally, additive manufacturing technologies are advancing rapidly across materials, equipment, and applications. While current focus often lies on the printing process itself, the upstream development of metal powders—particularly alloy design, production equipment, and low-cost spheroidization technologies—remains a critical yet underdeveloped area.

To support a robust and independent AM ecosystem, more attention must be paid to powder production infrastructure, process innovation, and material research. Building capabilities in these areas is essential for driving high-performance, cost-effective, and scalable metal 3D printing solutions.