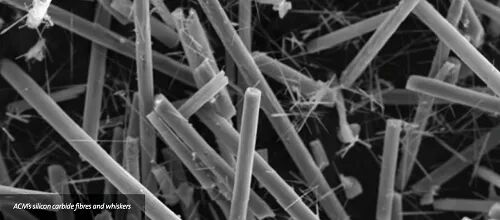

Inorganic whiskers are micro- to nanoscale short fibers formed through the growth of high-purity single crystals. With strength close to that of atomic bonds, complete cross-sections, minimal structural defects, and high aspect ratios, these whiskers...

Contact Us

Inorganic whiskers are micro- to nanoscale short fibers formed through the growth of high-purity single crystals. With strength close to that of atomic bonds, complete cross-sections, minimal structural defects, and high aspect ratios, these whiskers are widely used to enhance the physical and mechanical properties of polymers and composites.

Among many inorganic materials capable of forming whiskers, silicon carbide (SiC) stands out as a prominent example. As a covalently bonded ceramic, silicon carbide exhibits excellent comprehensive properties, including high strength, high thermal and electrical conductivity, extreme hardness, creep resistance, wear and corrosion resistance, oxidation resistance, and outstanding thermal stability.

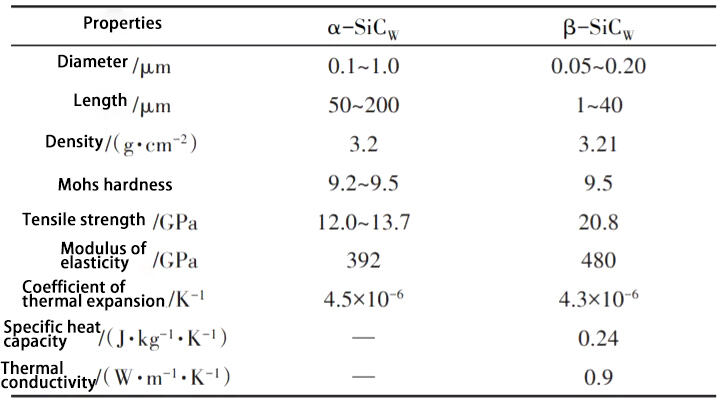

When formed into whiskers, SiC exists in two crystal structures: α-type and β-type, with β-SiC whiskers offering the highest known hardness, modulus, tensile strength, and heat resistance among whiskers. These whiskers are highly cost-effective and easily compatible with various matrix materials, making them the focus of extensive global research.

As a high-performance reinforcement material, SiC whiskers improve toughness and strength in composites by mechanisms such as crack deflection, crack bridging, whisker pull-out, and whisker breakage. Currently, they are widely used in metal matrix, ceramic matrix, and resin matrix composites.

Metal matrix composites typically use the following types of metals as matrices:

Aluminum (Al) and magnesium (Mg): lightweight, high specific strength.

Titanium (Ti): high melting point, excellent structural stability, outstanding high-temperature performance.

Iron (Fe) and nickel (Ni): high-temperature resistance, good magnetic permeability, low coercivity.

Copper (Cu), silver (Ag), and gold (Au): excellent conductivity, corrosion resistance.

SiC whisker-reinforced metal matrix composites exhibit remarkable improvements:

SiCW/Cu composites: enhanced tensile strength and balanced properties.

SiCW/Al composites: significantly improved specific stiffness, tensile strength, wear resistance, and reduced thermal expansion.

MB15 alloy with SiCW: increased hardness and aging rate.

Although ceramics are known for high-temperature resistance, corrosion resistance, and excellent mechanical performance at elevated temperatures, their inherent brittleness limits broader applications. Using whiskers to reinforce ceramics is one of the most effective ways to overcome these limitations.

Common fabrication methods for SiC whisker-reinforced ceramics include:

Hot pressing

Hot isostatic pressing

Pressureless sintering

Chemical vapor infiltration (CVI)

Spark plasma sintering (SPS)

Example applications:

SiCW-reinforced Al₂O₃/Ti₃SiC₂ composites: improved fracture toughness and bending strength.

SiCW-toughened ZrB₂ ceramics: enhanced flexural strength and toughness.

High-performance resin matrix composites are gaining popularity across industries due to their low density, high specific modulus and strength, fatigue resistance, vibration damping, corrosion resistance, and low thermal expansion.

In aerospace, weight reduction is crucial. However, to be used as load-bearing components, resin materials must meet strict performance requirements such as:

High-temperature resistance

Enhanced strength

Wave transparency and absorption

Electromagnetic stealth

SiC whiskers are a key solution to enhance these properties.

A notable example is a study by Guo Weiwei, who used SiC whiskers to reinforce UV-curable resin composites via stereolithography (SLA). By surface-treating the whiskers with coupling agent KH550, the study found that whisker addition:

Slowed the UV curing rate

Significantly improved mechanical performance

Had minimal negative impact on the curing process

SiCW in Ti(C,N)-based metal-ceramic composites: overall improvement in mechanical properties.

Today, SiC whisker-reinforced composites are used in diverse industries, including aerospace, defense, automotive, chemical processing, electronics, and biomedical fields.

Examples include:

Aerospace: bearings, fuel system valves, combustor batteries, radar antennae, infrared domes, helicopter and jet aircraft components.

Automotive: fuel injectors, low-emission internal combustion engines, heat engine components.

Chemical and energy: catalytic reformers, sealing nozzles, wear-resistant machine parts.

Electronics: multilayer capacitors, gas and pressure sensors.

Biomedical: artificial teeth, bones, joints, and implant materials.

With their outstanding performance, SiC whiskers are hailed as the “King of Whiskers” and have drawn significant attention from researchers worldwide. Countries like the U.S. and Japan began researching and industrializing silicon carbide whiskers early on, yielding strong technological and economic benefits. While China started later, rapid advancements have been made.

Promoting the study of SiC and other whiskers can elevate China’s capabilities in composite material science and significantly boost its global competitiveness, particularly in national defense.

Currently, SiC whiskers are most widely studied and applied in metal and ceramic matrix composites. Research on their use in resin matrices is still developing. For SiC whiskers to fully realize their potential in resin systems, deeper and more systematic studies on surface modification techniques are essential.