GT360 Industrial Metal Additive Manufacturing System

Description

The GT360 Industrial Metal Additive Manufacturing System is an advanced metal 3D printing solution based on powder bed fusion (PBF) technology. Engineered for high-volume and high-precision production, it transforms 3D digital models into functional metal parts by selectively melting layers of powder with dual high-power lasers.

Designed with industrial scalability and flexibility in mind, the GT360 is equipped with an intelligent software suite, open material compatibility, and a high-precision optical system—making it ideal for production in aerospace, automotive, tooling, healthcare, and research sectors.

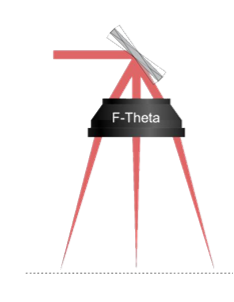

SLM optical system

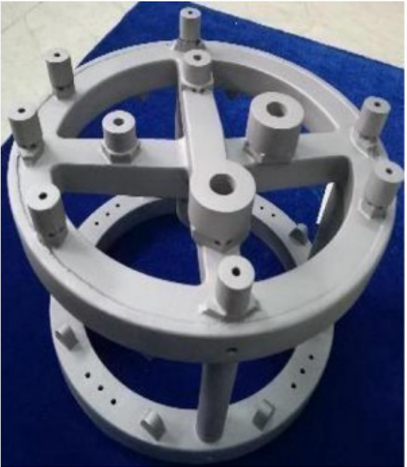

field mirror

The role of the 3D-printed field mirror is to transform curvature into flatness, converting a spherical surface into a flat surface as required by the device.

|

|

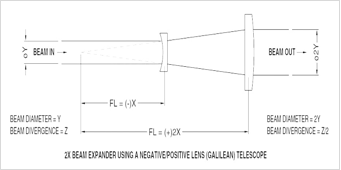

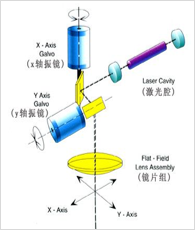

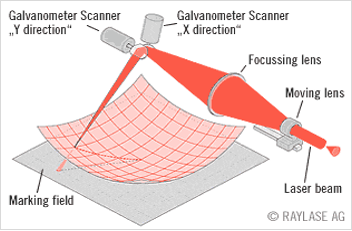

Beam expander /Scanner mirror

|

Beam expander |

Scanner mirror |

Features

Adaptable Powder Spreading System

Selectable blade materials to match various metal powders and part geometries.Operator-Friendly Interface

Visualized and intuitive software with easy maintenance access. Dual filtration ensures operator safety and environmental cleanliness.Exceptional Build Accuracy

Custom-designed optics and optimized airflow deliver high consistency, even across full-bed prints.Advanced Airflow & Dust Management

Enhanced airflow design ensures efficient removal of smoke and splatter, providing a clean and stable build environment.Intelligent Slicing Software

Proprietary path optimization reduces processing time. Open material system allows configuration of custom process packages.Complete Print Traceability

The system logs every aspect of the build process: layer count, chamber pressure, oxygen levels, material positions, and more—ensuring product consistency and quality assurance.

Benefits

Large build volume for complex part production

Compatible with a wide range of metals

Reduced post-processing due to clean edge quality

Designed for continuous, industrial-grade usage

Open software ecosystem for flexible operation

Technical Specifications

| Specification | Details |

|---|---|

| Device Size | 2200 mm × 1500 mm × 2450 mm |

| Max Build Volume | 350 mm × 350 mm × 300 mm |

| Molding Accuracy | ±0.05 mm |

| Layer Thickness | 20 – 100 μm |

| Spot Diameter | 75 μm |

| Laser Power | Dual 500W Lasers |

| Scanning Speed | 9 m/s |

| Forming Speed | 25 – 70 cm³/h |

| Powder Feeding Mode | Powder Cylinder Feeding (Top Loading) |

| Oxygen Concentration | ≤ 100 ppm |

| Shielding Gas | Nitrogen (N₂) / Argon (Ar) |

| Machine Weight | 2800 kg |

| Power Consumption | 8 kW |

| Software | Magics + BP, 3DXpert |

| Supported File Formats | STL, OBL, STEP, etc. |

| Applicable Materials | Stainless steel, tool steel, cobalt-chrome, high-temp alloys, titanium, aluminum alloys |

Applications

Aerospace – Structural and high-strength lightweight components

Medical Devices – Biocompatible implants and surgical tools

Automotive – High-performance parts, prototypes, and engine components

Mold & Tooling – Custom molds and inserts with complex cooling channels

R&D and Education – Research labs, universities, and prototyping centers

Jewelry & Custom Design – Fine metal parts with intricate detail

Case

|

Titanium alloy |

Aerospace field-shunt bracket (316L) |

|

Automotive Industry-Automotive Interiors |

Heat Exchanger |

|

Car hood |

Differential |

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR