Connecting with Robot Laser Welding is such a cool thing. It’s as if you had a special robot that could melt metal and stick it together with a laser beam. How awesome is that?

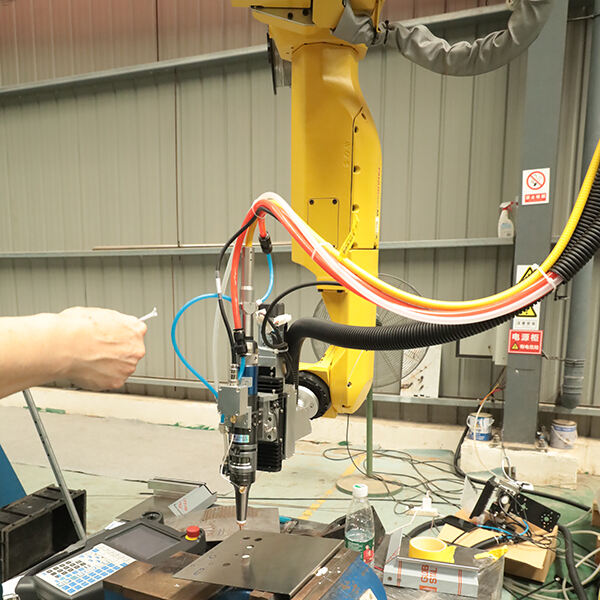

“The DMK robots are extremely smart, doing all kinds of cool things, like welding with a laser. Think of a robot with a laser beam shooting out of its arm, welding metal parts together to fuse them into a single piece. It’s magic, but it’s actually science!

So, what happens when you use Robot Laser Welding? First, sensors in the DMK robot search for the metal pieces that are to be welded. Then it deploys its laser beam to flush the metal with heat until it melts. Once the metal melts, the robot shoves the pieces together and lets them cool. And voila, the pieces are assembled!

Robot Laser Welding is high accuracy and fast. And because the DMK robot is so clever, it is able to weld metal pieces together with extreme precision. This also means there are fewer errors and less waste — which is great for the environment. Also, Robot Laser Welding is pretty quick, so things can get done in a fraction of the time it would take in traditional welding.

There are multiple advantages of using Robot Laser Welding in factories. It is also faster and more precise than traditional welding technology, and safer for workers, it claims. Because the DMK robot does all the heavy lifting, workers don’t need to be exposed to noxious heat or fumes. And Robot Laser Welding can be used on a large variety of materials, from thick metal to delicate plastic.

DMK is situated within the East Lake High-tech Development Zone in Wuhan. We are the enterprise that was highly-tech in the development, analysis and manufacturing of complete sets of laser equipment. The team which founded us comprises of postgraduate level holders, and we use an employee composed of a lot more than a dozen scientists which can be technical. With the production which is modern for laser equipment, too being an extensive after-sales division, we have been able to incorporate custom solutions for automated laser processing equipment to both worldwide and domestic clients. We additionally offering robot laser welding which are after-sales assist clients resolve any problems relating to the merchandise quickly.

We always adhere to the core values of "customer-centricity" and "creating customer-satisfying value." We think about customer needs near the top of our priority list. We earnestly take part in the "Made in China 2025 initiative" and utilize technology and services to assist in enhancing the efficiency linked with the robot laser welding. In line with the twin force of Internet+ and Industry 4.0 and Industry 4.0, we closely proceed with industry needs for the Internet that was industrial age. You may expect the important laser that is advanced level technology and application service in the business and collaborate with our lovers to achieve greater speeds, additional cost-effective and quicker growth.

At this time, our company has generated and provide that has been extensive, including eight biggest categories and an enormous choice of products {keyword} that is comprising are complete of laser cutting equipment, laser welding machines together with laser cleaning machines as well because just how to obtain different components like fiber lasers laser cutting heads, laser welding minds, laser cleaning minds, and laser control systems. Our goods were commonly used in various industries, like sheet metal processing and ecological protection equipment agricultural equipment, shipbuilding, aerospace, and power that was also new. Our goods, that could export and import by themselves, has a share that was growing of market which are areas which is global East Asia, North America and Latin America, Middle East, Western Europe and Russia.

With the constant development of fiber laser technology, we have included robot laser welding that is world-class and procedures. We partner with a few of the most reputable laser that are domestic and control system vendors like Raycus MAX, JPT Friendess Raytools SUP QILIN ESTUN. From the professional's view of laser processes, we carefully select every component of our equipment, strictly control construction processes, and conduct thorough inspections of the factory. We assist Chinese manufacturers to create better life for the world's consumers by this work.