Laser welding is a unique method of attaching tool steel pieces. It is precise and welds very good joint that hold up great! DMK, the company that makes the laser welding tools were using on tool steel, knows a great deal about how to use this technology on tool steel. Now that we know a little bit about what laser welding is, and when the best time to use it looks like, let’s get to know laser welding a bit better, as well as take a closer look at Handheld laser welding tool!

Laser welding is extremely precise, so it can make very small, very fine welds. This is crucial for tool steel that is used to manufacture tools such as drills and saws. By welding tool steel with a laser, DMK can make sure the welds are strong and accurate, so the tools will work perfectly every time.

There are a lot of positives to using laser welding with tool steel. One major advantage is that it does not generate much heat. This also prevents the steel from becoming weakened, or damaged when welding. Laser welding produces very little mess as well, which keeps the welds clean and tidy. And laser welding is many times faster than traditional welding methods, so DMT can produce the tools and get them out to customers in no time.

Laser welding improves an already perfect tool steel. By meticulously controlling the heat and welding settings, DMK is able to produce welds stronger and more durable than the steel itself. This helps tools last longer and perform better for the people who use them. Using laser welding, DMK is able to produce well-made tools.

With laser technology one of the best things is that you turn out getting such very tight welds tool steel is welding. In other words, the welds are bunched with little to no gap. That the welds are tight is crucial; this ensures that the tool steel is thoroughly welded together and won’t have any weak areas. Because DMK can make laser-brazed functional units, they can be certain their tools are’s tough and reliable.

Laser welding of tool steels is done by the DMK, which adopts different methods. This is so-called conduction mode welding, a method widely used among others. With this method, the hot surface of the steel is liquified for the two pieces to join. Keyhole welding is another process. In this process, a laser drills a small hole in the steel, then fill this with molten metal to form the weld. By using these techniques and more, DMK is able to produce high-quality welds on tool steel that can hold up to tough tasks.

DMK is found within the East Lake High-tech Development Zone in Wuhan. We have been an enterprise which are technical in analysis, development and manufacturing of complete laser welding tool steel. We have a real quantity of scientists and postgraduates on our creator's team. We now have the state-of-the-art production facility for laser equipment and a group comprised of after-sales professionals whom can afford to offer custom solutions to customers in the international and market which is domestic. We furthermore offer expert help that was after-sales help clients solve any product-related problems promptly.

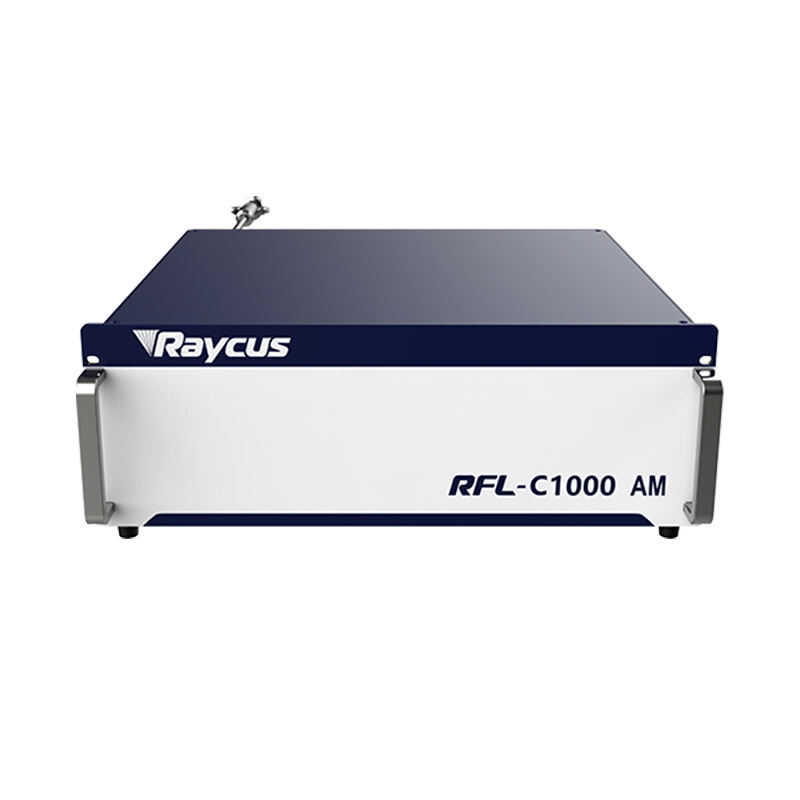

With the constant developing of fiber laser technology, we have included laser that is internationally leading and technologies. Collaborating with top domestic companies of laser equipment and control systems such as for instance Raycus, MAX, JPT, Friendess, Raytools, SUP, QILIN, and ESTUN We're committed to providing the market with affordable laser cutting, welding, cleansing, cladding, and marking tools. We very carefully choose elements for our laser welding tool steel, control assembly procedures, and conduct inspections which are rigorous the factory. We help Chinese manufacturers to improve life for all users worldwide with this work.

We always adhere to the core values of "customer-centricity" and "creating customer-satisfying value." We think about customer needs near the top of our priority list. We earnestly take part in the "Made in China 2025 initiative" and utilize technology and services to assist in enhancing the efficiency linked with the laser welding tool steel. In line with the twin force of Internet+ and Industry 4.0 and Industry 4.0, we closely proceed with industry needs for the Internet that was industrial age. You may expect the important laser that is advanced level technology and application service in the business and collaborate with our lovers to achieve greater speeds, additional cost-effective and quicker growth.

Our company presently possesses supply chain that comprises 8 categories of item as well because a range that is huge of material like complete machines for laser cutting, laser welding and laser cleansing, in option to components such as for example for instance nutritional dietary fiber lasers and laser minds. Our items are used commonly in industries like sheet metal equipment and processing for ecological protection. They have been used in agricultural equipment, shipbuilding’s, {keyword}, new energy in choice to shipbuilding. Our things, which could export and import independently and are growing in the share for the marketplace that has been regions which are global East Asia, North America and Latin America, Middle East, Western Europe and Russia.