Industrial laser welding machines have the potential to do amazing wonders! They use intense beams of light to weld materials together, for example, bits of metal. These machines are quite necessary to produce a lot of the things we use in our everyday life. Today we find out how industrial laser welding machines work and advance the world of manufacturing.

Industrial laser welding systems really are like magic machines that can magically turn two little parts into one. A heavy laser melts the edges of the metal parts. The molten metal cools and hardens, fusing the two pieces tightly together. This is fast and precise, so the wells are consistent and clean.

Previously it would take a long time and a lot of work to melt metal pieces together. Workers applied torches or different tools to heat up the metal and fuse the pieces together. But today, with industrial laser welding machines, the job is easier and much faster. This enables manufacturers to make more of a product in less time, saving money and boosting productivity.

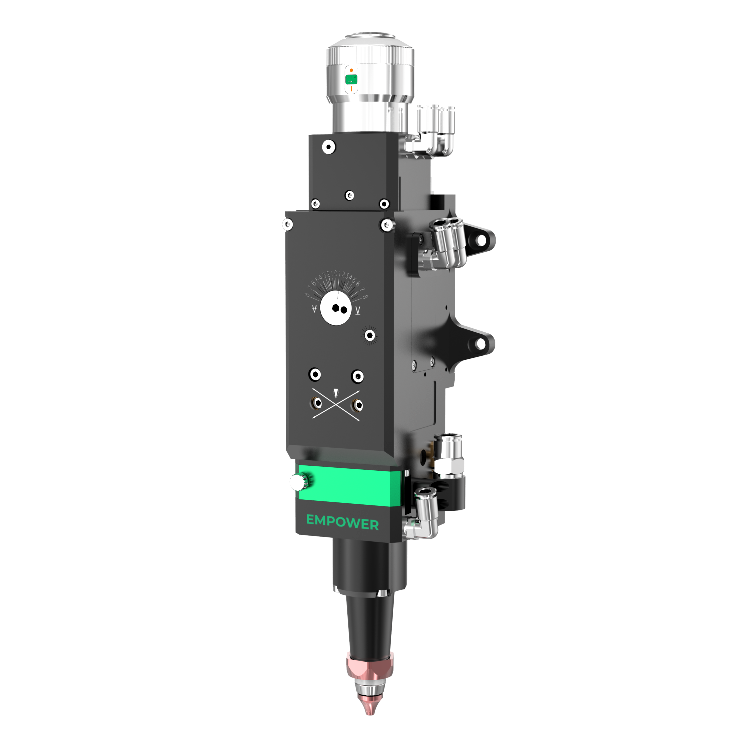

Industrial laser welding machines are capable of more than just welding pieces of metal together. They can even precision cut and shape metal components. This makes them so useful to so many industries, from cars to planes. These machines help produce many products we use every day, such as cars and electronics.

Industrial laser welding machines are revolutionizing the welding industry by doing everything faster, more precise and cheaper. They will also improve the quality of welds, so that fewer mistakes are made. It enables companies to deliver better products that are safer and more dependable. And that’s why these machines should be mission-critical for any company that wishes to keep pace in today’s accelerating world.

Industrial laser welding machines are stronger and better today due to newly developed technology. New machines can weld heavier materials and work faster than ever. And they’re simpler to use, too, with the kind of features that just make them easy to handle and keep. These enhancements are some of the reasons why laser welding makers are increasingly valuable for manufacturers around the world.

In the ongoing developing of fiber laser technology we've applied laser which is globally leading and technologies. We collaborate with the most effective laser that was domestic and device manufacturers like Raycus MAX, JPT Friendess Raytools SUP QILIN ESTUN. We very carefully select components we use for our laser equipment. We also control industrial laser welding machine and bring down inspections which can be thorough the factory. In this genuine way we allow Chinese manufacturing to continue to provide the better experience for global users.

Currently, our company has the supply chain encompassing 8 areas that are main a range that is big of these because the production that are complete of cutting machines, laser welding machines, laser cleansing machines, and the strategy of getting elements like fiber lasers, cutting lasers, laser welding minds, laser cleansing minds, also as laser control systems. Our products are commonly used in industries such as for instance sheet {keyword} processing and protection which is environmental vessels, agricultural machinery, aerospace, and the development of new energy. The Middle East, Western Europe and Russia with the capacity to import and export items that have accumulated a share that keeps growing of marketplace in international markets, such as for instance for instance East Asia, North America, Latin America.

DMK is found inside the East Lake High-tech Development Zone (Optics Valley) situated in Wuhan, China. We have been the firm which try high-tech specializes in development, research, production and purchase of complete laser equipment. You can find the dozen that are few and researchers on our founder's team. With the laser that was industrial laser welding machine base and a considerable after-sales department, we are able to provide customized options for laser processing equipment that was automated to international and domestic customers. We also offering professional after-sales assistance to assist users solve any pressing issues with their products or services quickly.

We constantly adhere to the core values of "customer-centricity" and "creating customer-satisfying benefits." We give consideration to consumer specifications towards the top of your number of priorities. We actively take part in the "Made in China 2025 initiative" and use technologies and services to upgrade the laser industry intelligently. Inspiring by the two forces of Internet+ and Industry 4.0 and Industry 4.0, we closely proceed with the needs that is due to the Internet which was industrial age. We provide the important advanced level industrial laser welding machine and application-related services in the business and collaborate with our supply chain to assist clients get faster, better, and additional growth which is effective.