Robot laser welding is revolutionizing how things are made in our world today. At DMK, we can't wait to show you how this incredible technology is driving manufacturing forward. Let’s take a look at the fascinating universe of Robotic Laser Equipment!

No big surprise; precise robotic laser welding is that good. With painstaking accuracy but without a tremor or an emotion, a robot can now weld more precisely than ever, using a laser as the flame. This ensures each weld is strong and reliable, saving you the work of fixing mistakes later.

Robotic laser welding is redefining how things are made, by making manufacturing faster and more cost-effective. Robots can make factories more efficient by speeding production of goods. This technology is enabling better designs and new things that we couldn’t do with the old welding technology.

It’s a bright future for welding with robotic laser technology. With this technology, we will witness faster, more accurate and versatile welding, as this technology improves further. Robots weld an array of materials and thicknesses, too, making them an attractive option for manufacturers looking to sock it to the competition. The future is now for welding, and it’s looking bright, with robots and lasers!

Robotic laser welding systems are a wise investment for manufacturers. They save money, work faster, weld better. These systems are capable of performing a wide range of welding tasks, and so can be reconfigured for different production needs. Robot laser welding system investing is not a bad decision and we can get good returns for long time.

One great advantage of robotic laser technology is that it creates stronger welds than traditional welding. Robotic systems form strong and reliable welds by using a laser to heat and join metals. These sound welds are critical for items that are designed to be durable and work well. Manufacturers can create welds that they can be proud of that are better looking, and better differentiate them from their competition through robotic laser technology.

We constantly adhere to the core values of "customer-centricity" and "creating customer-satisfying benefits." With customer requirements in the concern that is first we implement the "Made in China 2025" initiative and use technologies and services to assist in the smart upgrade of the laser production. In line with the force that is dual the Internet+ and Industry 4.0, we closely align with criteria about the robotic laser welding. We provide the laser intelligence technology which try newest in choice to application service since you can to find, and perform with our lovers to achieve greater, faster and more useful growth.

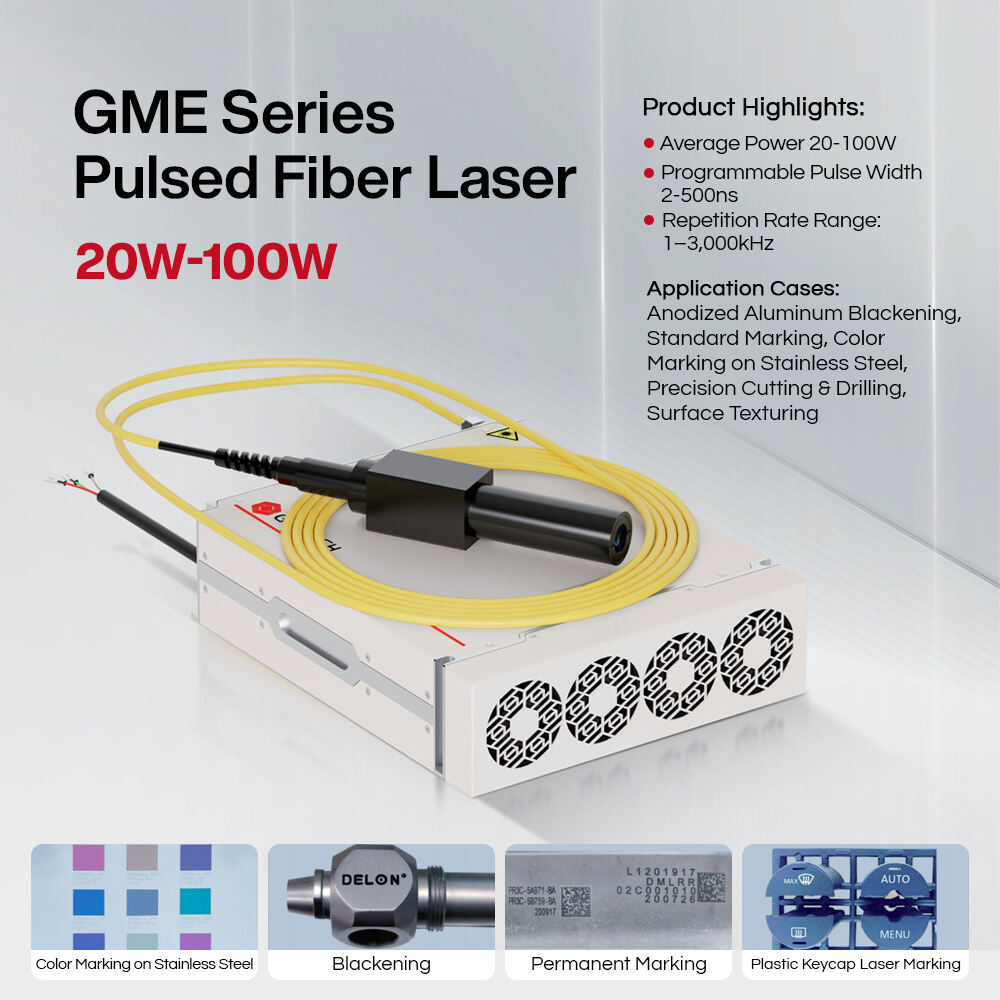

Our company has a supply chain which include 8 biggest categories of products too as the selection that was big of things like complete machines which may be used for laser cutting, laser welding and laser cleaning, in selection to components such as for example dietary fiber lasers and laser minds. Our products are generally used in industries such since for instance sheet metal processing equipment for environmental protection, delivery, agricultural equipment aerospace, and {keyword} that is also new. Our merchandise, that may manage to import and export independently, have share which keeps growing of world marketplace throughout regions such because East Asia, North America and Latin America, Middle East, Western Europe and Russia.

Due to the fact world continues to advance in robotic laser welding technology, we've included laser which is world-class and procedures. In collaboration with top suppliers in the US of lasers and control systems, such since Raycus, MAX, JPT, Friendess, Raytools, SUP, QILIN, and ESTUN We are dedicated to provide affordable laser cutting to our customers, welding, cleaning, cladding, and marking tools. From the professional's attitude, in laser procedures, we carefully choose each element of our equipment, rigorously monitor assembly processes, and conduct rigorous inspections of the factory. With these efforts we can allow Chinese manufacturing to continue to give a better experience for global consumers.

DMK is situated inside the East Lake High-tech Development Zone in Wuhan. We're the firm which are highly-tech concentrates on research, developing and production of complete sets of robotic laser welding. We have true range postgraduates and scientists in our creator's group. We have production which was modern for lasers and a group comprised of after-sales specialists whom can afford to provide custom solutions to customers in the market in both nations. We offer professional after-sales services to solve any problems being product-related.