And joining things one to another by running a fiber laser across some material is a really cool way to do it. It’s like waving a magic wand that transforms metal pieces into one! So, in this post, let’s take a closer look at how fiber laser welding operates — and why it’s so awesome.

Fiber laser cleaning machine: Really, really precise. It fuses together the smallest bits of metal effortlessly. The laser beam is a kind of intense light that melts the metal just enough to form a strong bond. This that we can create very intricate designs and tiny parts that we don’t have to worry about breaking. We can build things with fiber laser welding that are not only pretty, but strong.

One of the great things about fiber laser welding is how fast it is! This is what allows us to make things faster than with old welding methods. It also produces less heat, which prevents the metal from warping or damaging during welding. Plus, fiber laser welding is highly efficient, meaning we can save time and energy and still get an excellent result. You really do get the best of both worlds!

Fiber laser rust removal machine is revolutionizing the way things are being made. It enables us to design new and interesting products that we wouldn’t have been able to manufacture before. Now we can do things faster and better than ever with its speed and accuracy. This is good news: We can meet the increasing demand for goods while also ensuring their quality. We can investigate new dimensions in manufacturing with fiber laser welding.

Another advantage of fiber laser welding is that it can be used with a wide range of materials. Metal, plastic, even ceramic: Fiber laser welding can weld them together to perfection. That means we can do many different kinds of projects without having to switch welding types.” It’s like a specialty welding tool who gets to do every job!

Fiber lasers welding make our work more efficient and productive. We can complete jobs quicker and with better outcomes by having this advanced technology at our fingertips. This gives us the ability to accept more projects and meet deadlines without sacrificing quality. With fiber optic laser welding, we can work smarter, not harder – something that everyone can appreciate!

We always adhere to the core values of "customer-centricity" and "creating customer-satisfying value." We think about customer needs near the top of our priority list. We earnestly take part in the "Made in China 2025 initiative" and utilize technology and services to assist in enhancing the efficiency linked with the Fiber laser welding. In line with the twin force of Internet+ and Industry 4.0 and Industry 4.0, we closely proceed with industry needs for the Internet that was industrial age. You may expect the important laser that is advanced level technology and application service in the business and collaborate with our lovers to achieve greater speeds, additional cost-effective and quicker growth.

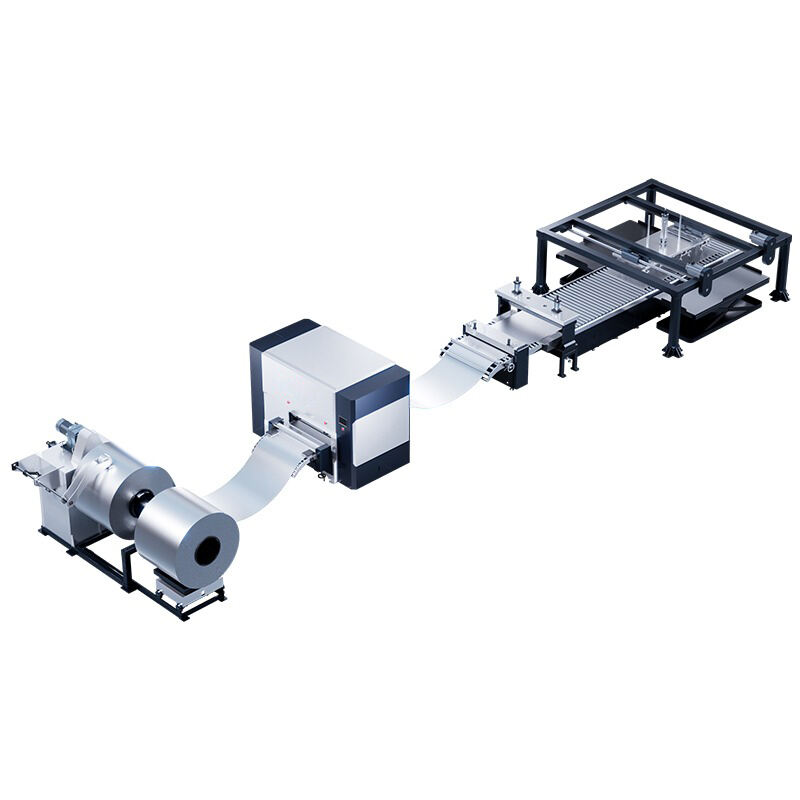

Our company possesses an offer that was considerable which comprises 8 biggest types of products and the selection which is big of, such because complete machines for laser cutting, laser welding, and laser cleansing. We furthermore have actually equipment like fiber lasers and laser minds. Our things are widely used in industries like sheet metal processing because well since equipment for ecological protection. Additionally, they find use in the industries of {keyword}, shipbuilding’s and aerospace, together with new shipbuilding and power. Our products, which may import and export independently and are growing in the share of this marketplace internationally in regions like East Asia, North America and Latin America, Middle East, Western Europe and Russia.

DMK try situated in the East Lake High-Tech Development Zone (Optics Valley) positioned in Wuhan, China. Our company is a company that are highly-tech are expert in research, development, and manufacturing of complete sets of laser equipment. We now have a few dozen postgraduates and researchers in our creator's team. With our contemporary manufacturing center for laser equipment, along with a skilled staff that is after-sales can afford to provide custom solutions for Fiber laser welding processing equipment to domestic and worldwide users. We offer the professional service which was after-sales resolve any product-related problems quickly.

With the constant development of fiber laser technology, we have included Fiber laser welding that is world-class and procedures. We partner with a few of the most reputable laser that are domestic and control system vendors like Raycus MAX, JPT Friendess Raytools SUP QILIN ESTUN. From the professional's view of laser processes, we carefully select every component of our equipment, strictly control construction processes, and conduct thorough inspections of the factory. We assist Chinese manufacturers to create better life for the world's consumers by this work.