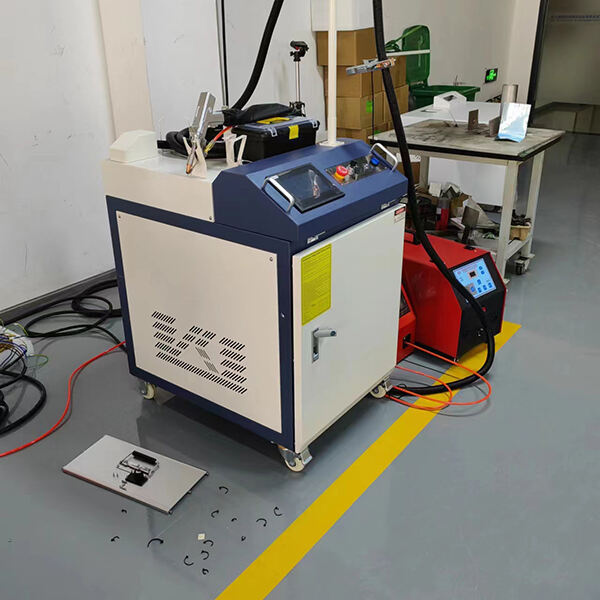

Fiber Laser Welder by DMK: The Newest Technology for Welding

Do you ever hear of fiber laser welder? It's the current and most technology that was advanced welding. We will explore the benefits, innovation, protection, utilize, utilizing, provider, quality, plus application of DMK's fiber laser welder.

Fiber laser welder is obviously a cutting-edge technology that provides importance that could be many welding that is conventional. To begin with DMK's fiber laser welding machine, it offers accuracy which are higher precision in welding, that decreases the need for post-weld finishing. Next, it decreases heat input into the product, that minimizes the warping and distortion for this components being welded. Thirdly, it might weld several kinds of components, like metals, alloys, plus plastic materials, with a high effectiveness plus effectiveness.

Fiber laser welder is certainly a technology which try revolutionary uses fiber optics to send laser energy to your welding mind. The laser beam is concentrated by means of a lens regarding the work piece, making a thickness which are high-energy that melts and fuses this product. This DMK's fiber laser welding technology enables accurate plus welding which was managed since the laser beam may be modified to fit the welding specifications.

Fiber laser welder is simply a technology that was safer utilize, since it will not give off radiation that is harmful fumes through the welding procedure. Furthermore, DMK's handheld fiber laser welder reduce steadily the probability of injuries, such as for example fire plus explosion, as it minimizes the heat input plus creates spatter which are minimal. Nevertheless, it is crucial to hold appropriate individual equipment that has been protective such as for example welding goggles plus gloves, whenever fiber laser welder that is using.

Fiber laser welder is not hard to make use of and requirements classes that are minimal work. First, you will want to ready the work piece up and align it while using the welding mind. Next, you need to adjust the fiber laser welding machine handheld parameters, such as for example energy plus pulse regularity, to match the materials and welding joint. Finally, the welding is beginning by the procedure by activating the laser beam plus going the welding mind across the welding course.

We always adhere to the core values of "customer-centricity" and "creating customer-satisfying value." We think about customer needs near the top of our priority list. We earnestly take part in the "Made in China 2025 initiative" and utilize technology and services to assist in enhancing the efficiency linked with the Fiber laser welder. In line with the twin force of Internet+ and Industry 4.0 and Industry 4.0, we closely proceed with industry needs for the Internet that was industrial age. You may expect the important laser that is advanced level technology and application service in the business and collaborate with our lovers to achieve greater speeds, additional cost-effective and quicker growth.

DMK is found inside the East Lake High-tech Development Zone (Optics Valley) situated in Wuhan, China. We have been the firm which try high-tech specializes in development, research, production and purchase of complete laser equipment. You can find the dozen that are few and researchers on our founder's team. With the laser that was Fiber laser welder base and a considerable after-sales department, we are able to provide customized options for laser processing equipment that was automated to international and domestic customers. We also offering professional after-sales assistance to assist users solve any pressing issues with their products or services quickly.

Our company has produced a supply chain that covers eight biggest areas and a range which is huge of machine that was comprising are complete of laser cutting equipment, laser welding machines, laser cleaning machines, and the strategy to getting parts like fiber lasers cutting lasers, laser welding heads and laser cleansing minds and laser control systems. Our items are used extensively in industries such since for instance sheet steel equipment and processing for environmental protection. They are often used in {keyword}, shipbuilding’s and aerospace, also since new energy along with shipbuilding. Our things, that can export and import independently and keeps growing in the share of the markets internationally in places like East Asia, North America and Latin America, Middle East, Western Europe and Russia.

With the constant development of fiber laser technology, we have actually incorporated laser that try world-class and technology. We collaborate with the Fiber laser welder which is domestic and control system companies such as for instance Raycus MAX, JPT Friendess Raytools SUP QILIN ESTUN. From the professional's view of laser processes, we bring worry to pick every component of our equipment, rigorously monitor assembly processes, and conduct rigorous inspections for the factory. Through these efforts we make it possible for manufacturing which is Chinese continually develop a better lifestyle for global customers.

To utilize fiber laser welder, you'll want to follow these methods:

1. Clean the work piece plus eliminate any contaminants, such as oil plus rust.

2. Put the work piece up and clamp it set up to produce security that is sure welding.

3. Align the welding mind utilising the welding joint plus adjust the laser parameters, such as for example energy plus pulse regularity.

4. Begin the welding procedure by activating the laser beam plus going the welding mind on the welding course.

5. Monitor the welding procedure plus adjust the laser parameters if required.

Fiber laser welder calls for repair that are regular provider to be sure performance that is optimized durability. The services include cleaning the optics, checking the laser power, plus changing components being worn-out like the nozzle plus lens. It is strongly recommended to schedule repair that has been regular services periods with all the maker as authorized dealer to avoid any downtime as breakdown.

Fiber laser welder creates top-notch plus welds being exact meet or surpass markets guidelines plus specs. The welding process are managed and supervised by advanced level sensors plus systems which assure persistence plus precision into the welds. Moreover, fiber laser welder decreases the need for post-weld finishing, such as for example grinding and polishing, which saves time plus expense.

As with every device, it is vital to ensure that your fiber laser welder is of good quality and comes with good customer service. Happily, the DMK's laser welding equipment is established with top-notch materials and is sold with a guarantee that will protect you in case there is any defects or malfunctions.

Furthermore, numerous manufacturers provide customer support which help for their fiber laser welder, which can help you will get probably the most through the device. Good customer care group can be quite a resource that is valuable you may need help with setup, troubleshooting, or just have actually questions about your fiber laser welder.