Conformal Cooling Channels in Molds: Challenges and SLM's Breakthrough When it comes to mold manufacturing, "conformal cooling channels" are key to improving efficiency and product quality – they can precisely control temperature by conforming ...

Contact Us

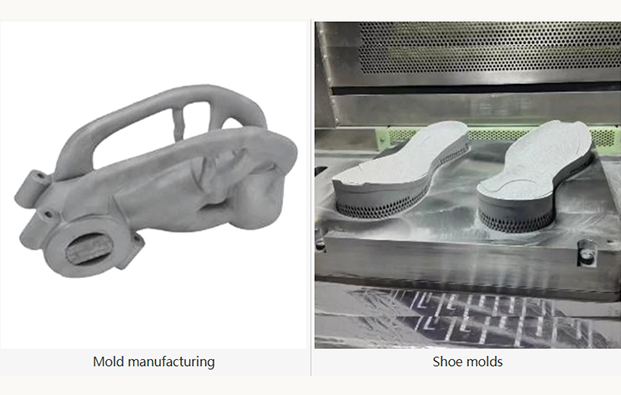

When it comes to mold manufacturing, "conformal cooling channels" are key to improving efficiency and product quality – they can precisely control temperature by conforming to the mold shape, reducing plastic part warpage. However, traditional processing technologies struggle to achieve integrated forming of complex cooling channels, a challenge that SLM 3D laser printers have successfully overcome.

The core of SLM (Selective Laser Melting) technology is using lasers to layer-by-layer melt and solidify metal powder, stacking up three-dimensional parts like "building blocks." In manufacturing molds with conformal cooling channels, its advantages are prominent: there's no need to split mold inserts, it can directly print structures with internal complex cooling channels, and the density can reach over 99.5% with mechanical properties superior to conventional processes.

However, printing qualified cooling channel inserts with SLM requires three steps: first, pre-forming preparation, which includes designing 3D models, adding supports (to prevent printing deformation), and determining process parameters (such as laser power and scanning speed); second, SLM forming, where the equipment melts metal powder (commonly S136 mold steel powder) according to a set path under inert gas protection, layer by layer; finally, post-processing, which involves cleaning residual powder, sandblasting to improve surface finish, and heat treatment if necessary to eliminate internal stress.

There are also considerations in printing methods: full printing is suitable for inserts with thin bases, offering uniform overall heating and low cracking risk but with higher material costs; graft printing builds key features on prefabricated blanks, which is more cost-effective but requires matching between the base and printed materials to avoid interface cracking. In practical applications, engineers choose based on insert size and cost requirements – for example, a mold insert for an oven component achieved precise cooling channel formation through full printing, and the plastic part's dimensional accuracy fully met standards after test molding.

Today, SLM 3D laser printers have become "game-changers" in complex mold manufacturing: they break the structural limitations of traditional processing, turning conformal cooling channel designs from blueprints into practical components; they shorten mold development cycles, reduce enterprise production costs, and help elevate plastic part quality to new heights. As processes continue to optimize, SLM 3D laser printers will undoubtedly release greater potential and create more value in mold manufacturing and even more high-end manufacturing fields, becoming a vital force driving industrial upgrading!