In the entire chain of automotive manufacturing, information marking on components and whole vehicles is a key link in ensuring quality and tracing origins. Relying on its unique technical advantages, the fiber laser marking machine is gradual...

Contact Us

In the entire chain of automotive manufacturing, information marking on components and whole vehicles is a key link in ensuring quality and tracing origins. Relying on its unique technical advantages, the fiber laser marking machine is gradually replacing traditional marking methods and has become an important tool for achieving refined and intelligent management in the automotive industry.

Automotive Industry Applications: From Basic Marking to Intelligent Tracing

Laser marking is not a simple replacement for traditional methods such as casting, hot stamping, and flexible labels-while the latter can only present basic information like product names, serial numbers, production dates, and batches, laser marking further demonstrates irreplaceable core advantages on this basis. It adopts non-contact processing, without direct contact with parts. During processing, the local thermal effect on parts is minimal, and the marking line precision can reach the micrometer level, which will not affect the original precision and assembly tolerance of parts at all. Meanwhile, the marking process is clean and pollution-free, with no additional consumables required, significantly reducing the unit marking cost.

More importantly, laser marking can quickly generate a unique QR code for each part. This function has become a core link connecting "industrial production" and "information management", representing a breakthrough that traditional methods cannot achieve. In accordance with the relevant national requirements for automotive component coding and identification, vehicle recall systems, and new energy vehicle access management, automakers and suppliers must establish unique identification codes for component assemblies, build information databases supporting product tracing, and jointly establish traceability information management systems to achieve full-process control over vehicle configurations, factory inspection data, and other aspects.

QR codes perfectly meet this demand: they can be marked in an extremely small area (even 2×2mm on electronic devices) while carrying massive amounts of information such as text and images. Moreover, they can be quickly recognized by scanning equipment, which neither affects the production rhythm nor greatly reduces the error rate of manual data entry. In various links of automotive production, manufacturing, and marketing, QR codes are like the "electronic ID cards" of parts, enabling accurate and rapid information transmission.

|

|

Addressing the pain point where counterfeit and shoddy automotive parts disrupt the market order and harm consumers' interests, the "uniqueness" of laser marking plays a more important role. Some enterprises mark original parts with unique codes or encrypted QR codes, binding information such as document numbers, part names, part numbers, supplier names, marking times, marking machine numbers, and operator information to the marks. Users can easily verify authenticity through the enterprise's dedicated inquiry channels. This model not only realizes the full-life-cycle traceability of parts but also accelerates the feedback and handling efficiency of quality issues, effectively enhancing car owners' trust in the enterprise.

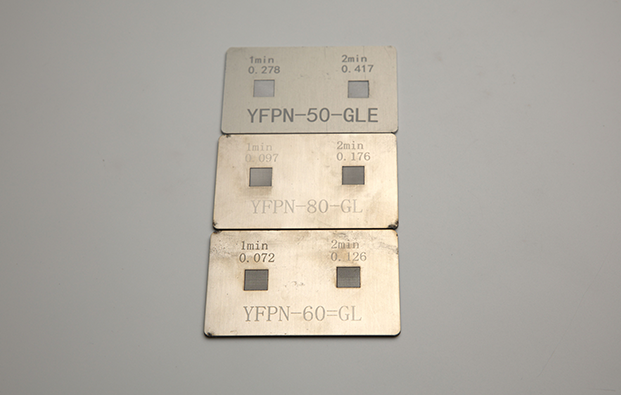

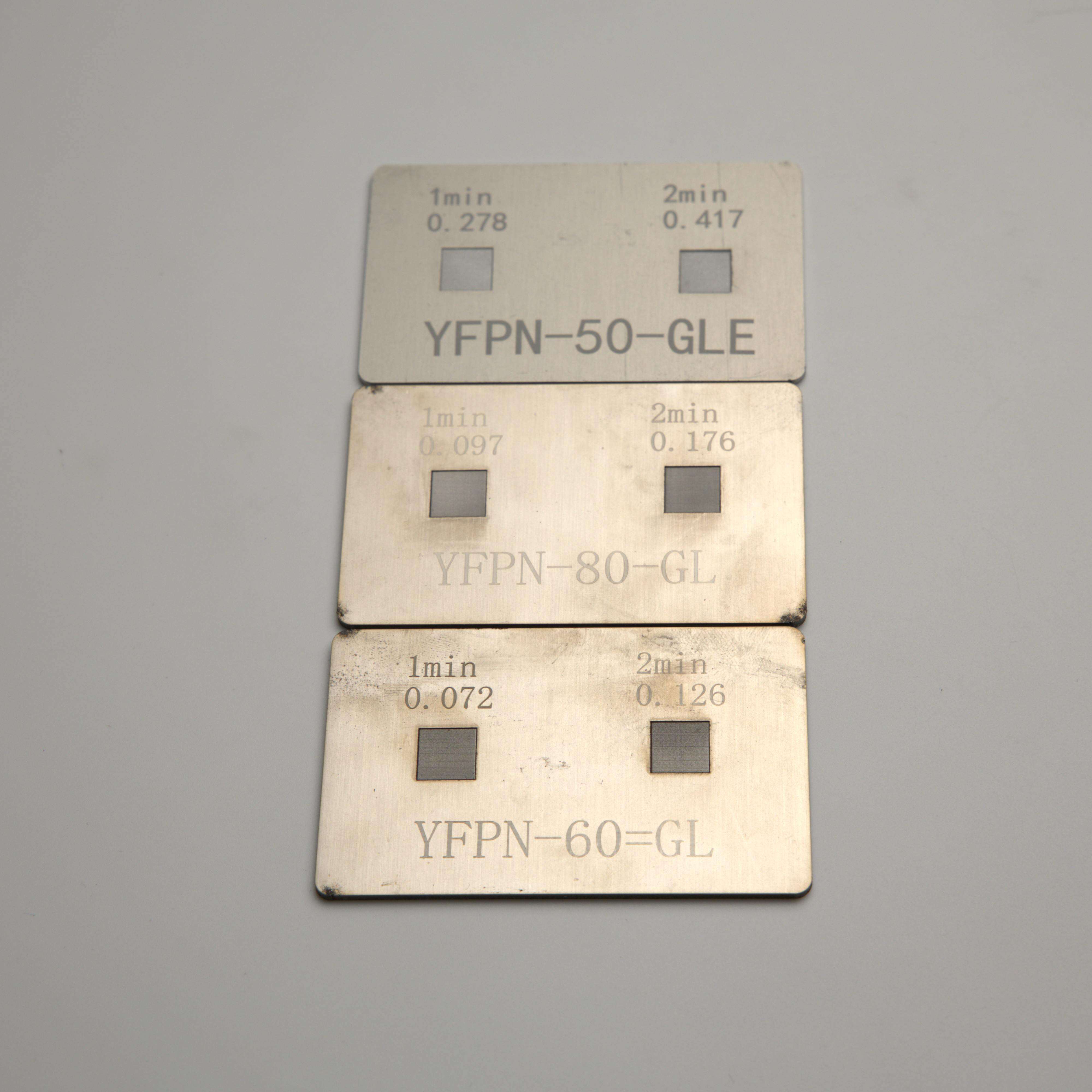

Parameter Settings: The "Core Code" for Material Adaptation

Numerous parameters affect the marking effect, such as settings for workspace, object properties, filling, text, and bitmap. The commonly used parameters are speed, power, and frequency, which need to be adjusted according to the material and surface treatment of the part being marked.

(1) Speed: Refers to the speed of the scanning galvanometer. The overall marking time is affected by speed parameters, marking depth, and marking area. With other factors unchanged, the faster the speed, the shorter the marking time, but the fewer times the same area is irradiated by the laser, resulting in a shallower mark. If the speed is too slow, the material ablated by the laser will accumulate on the part surface, affecting the marking depth. Therefore, to achieve deep marking, a method of marking multiple times at a low speed first and then once at a high speed can be adopted.

(2) Power: Refers to the percentage of the output power relative to the rated laser power, which can be adjusted between 0% and 100%. Higher power means greater output energy and more obvious ablation effect, and vice versa. The selection of power depends on the part material, surface treatment, and filling parameters. Long-term operation at high power will affect the service life of the laser.

(3) Frequency: Refers to the number of pulses per unit time. The higher the frequency, the denser the laser spots on the marking line, and the smoother the marking effect, and vice versa. The parameters need to be set differently according to different materials. The most commonly used frequency range is 20~100KHz. Low frequency exhibits a mechanical effect and works well on materials such as metals and silica gel; high frequency shows a burning effect and is more suitable for materials like plastics and PC.

Conclusion: The "Marking Cornerstone" of Intelligent Manufacturing

With the rapid development of information technology, the automotive manufacturing industry is accelerating its transformation from the traditional manufacturing model to the intelligent manufacturing model. In this process, as an important carrier integrating "industrialization + informatization", the fiber laser marking machine, through its precise and efficient marking functions, enables accurate, real-time, and scientific management of the entire process including production, storage, shipment, sales, and after-sales service. It not only meets the core needs of policy compliance and quality tracing but also becomes a key support for improving industry work efficiency and advancing the implementation of intelligent manufacturing.