- Главная страница

- Продукция

- О Нас

- Видео

- Применение

- Новости

- Центр Поддержки

- Свяжитесь с нами

Введение От электромобилей до самолетов следующего поколения, мировая индустрия производства переживает масштабные изменения. В центре этих изменений стоит потребность в более легких, прочных и устойчивых материалах. Среди наиболее...

Свяжитесь с нами

От электромобилей до самолетов следующего поколения, мировая индустрия производства переживает масштабные изменения. В центре этих изменений стоит потребность в более легких, прочных и устойчивых материалах . Среди наиболее перспективных инноваций — Термопласты, армированные непрерывными волокнами (CFRTP) — материал, который сочетает лёгкость, высокая производительность, прочность и перерабатываемость переопределить будущее высокотехнологичного производства

Благодаря своим исключительным механическим свойствам и растущему числу применений, КФТР занимает позицию, позволяющую открыть рынок стоимостью в сотни миллиардов , преобразуя такие отрасли, как аэрокосмическая промышленность, автомобилестроение, электроника и другие. Вопрос уже не в том, сумеет ли iF КФТР стать доминирующим, а в том, насколько быстро .

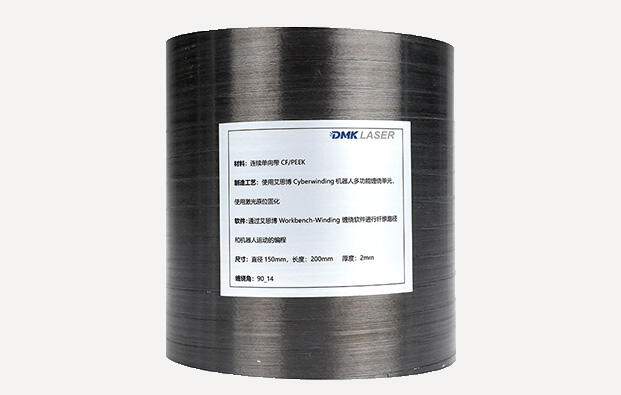

Непрерывно-волокнистый термопластик это композитный материал, включающий непрерывные волокна, как правило, углеродные, и термопластичную смолу в качестве матрицы. Это уникальное сочетание обеспечивает идеальный баланс между прочность и гибкость , при этом решая ключевые вопросы устойчивого развития благодаря возможности переработки.

В отличие от термореактивных композитов, CFRTP можно повторно нагревать и придавать ему новую форму, что позволяет производителям сокращать отходы и повышать эффективность производства. Его адаптивность и потенциал сокращения затрат делают его прорывным решением для массового производства в отраслях, где важны высокие эксплуатационные характеристики и устойчивое развитие.

Почему мировые производители выбирают КФТР ?Ответ кроется в его многоуровневых преимуществах по сравнению с традиционными металлами и пластиками:

Сверхлегкий и невероятно прочный

CFRTP весит на 40% меньше, чем алюминий, и на 80% меньше, чем сталь , но при этом обладает прочностью до четырех раз превышающей прочность алюминия на единицу массы .

Сопротивление коррозии и усталости

В отличие от металлов, CFRTP не ржавеет и не подвергается коррозии, сохраняя целостность конструкции при экстремальных нагрузках и многократном воздействии напряжений.

Термальная стабильность

Температурный коэффициент расширения составляет примерно в 10 раз меньше, чем у стали , что обеспечивает размерную стабильность CFRTP в условиях высокой температуры.

Устойчивое развитие

Его возможность вторичной переработки способствует глобальным целям по производству экологичной продукции, а также короткие циклы формования повышают скорость производства и экономическую эффективность.

Преимущества СFRTP открывают инновации в различных отраслях:

Аэрокосмическая промышленность: Более легкие компоненты самолетов уменьшают расход топлива и выбросы углерода.

Автомобильная промышленность: Важно для электромобилей, чтобы увеличить запас хода батареи и улучшить безопасность при столкновениях.

Потребительская электроника: Повышает прочность и премиальный внешний вид для ноутбуков, смартфонов и носимых устройств.

Медицинские устройства: Обеспечивает прочность и биосовместимость для хирургических инструментов и протезов.

Спорт и отдых: Высокопроизводительные велосипеды, ракетки и снаряжение для активного отдыха зависят от СFRTP из-за соотношения прочности и веса.

Несмотря на свои перспективы, CFRTP сталкивается с рядом препятствий на пути к массовому внедрению:

Высокая стоимость материалов:

Премиальные термопластичные смолы, такие как ПИК дорогостоящие и находятся под контролем небольшого числа глобальных поставщиков.

Сложные производственные процессы:

Узкие допуски по температуре и давлению затрудняют обработку CFRTP без использования передовых систем.

Инвестиции в оборудование:

Большинство производственных технологий находятся под контролем европейских и американских компаний, что увеличивает начальные затраты на установку.

Несмотря на эти трудности, рыночные перспективы для CFRTP никогда ранее не выглядели столь оптимистично. Несколько совпадающих факторов ускоряют внедрение:

Автомобильная электрификация и облегчение конструкции:

Производителям электромобилей требуются легкие решения для увеличения запаса хода и повышения эффективности — CFRTP идеально подходит для этого.

Технологические прорывы в автоматизации:

Инновации, такие как Автоматизированная укладка волокна (AFP) и 3D-печать для композитов сокращают производственные затраты.

Прогнозируемое снижение затрат:

С увеличением масштабов производства и ростом конкуренции ожидается, что стоимость CF/PEEK снизится до 500 юаней/кг в течение 3–5 лет , что сделает CFRTP экономически конкурентоспособным по сравнению с алюминием.

Экологические нормы:

Регуляторное давление в отношении устойчивых и перерабатываемых материалов дополнительно укрепляет стратегическое преимущество CFRTP.

Если эти тенденции сохранятся, ожидается, что CFRTP завоюет рынок на сотни миллиардов , в конечном итоге оспаривая алюминий и сталь как основной выбор для конструктивных компонентов.

| Свойство | КФТР | Алюминий | Сталь |

|---|---|---|---|

| Плотность (г/см³) | 1,5 – 2,0 | ~2.7 | ~7.8 |

| Удельная прочность | Очень высокий | Умеренный | Низкий |

| Стойкость к коррозии | Отличный | Умеренный | Бедная |

| Тепловое расширение | Очень низкий | Умеренный | Высокий |

| Возможность вторичной переработки | Да | Да | Да |

| Сопротивление усталости | Отличный | Хорошо | Умеренный |

CFRTP — это не просто еще один материал, это основа для следующей волны промышленных инноваций . Комбинируя легкий дизайн, превосходные механические свойства и возможность переработки , CFRTP решает ключевые задачи современного производства: эффективность, устойчивость и высокую производительность.

По мере снижения стоимости и развития производственных технологий переход на CFRTP будет ускоряться, открывая огромные возможности для тех, кто первым примет эту технологию. Для компаний, стремящихся оставаться конкурентоспособными в аэрокосмической, автомобильной, электронной промышленности и других отраслях, сейчас самое время инвестировать в решения на основе CFRTP .