- Página Inicial

- Produtos

- Sobre Nós

- Vídeos

- Aplicação

- Notícias

- Central de Ajuda

- Contacte-nos

Lidera a Atualização do Processamento de Placas Extra Grossas. Placas grossas e extra grossas são amplamente utilizadas em máquinas industriais, pontes, engenharia marítima e fabricação de componentes estruturais pesados. A qualidade do corte afeta diretamente o desempenho estrutural do conjunto...

Contacte-nos

Lidera a Atualização do Processamento de Placas Extra Grossas

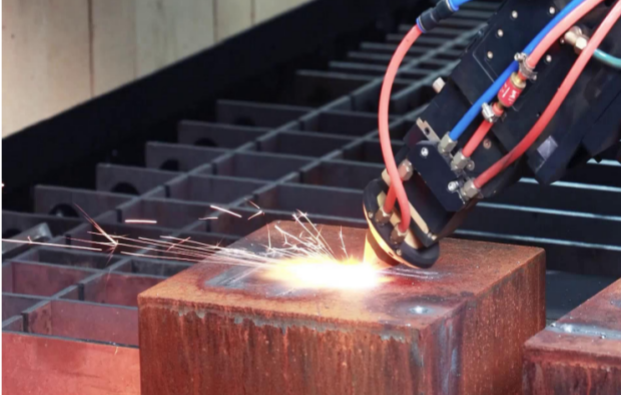

Chapas grossas e extra-grossas são amplamente utilizadas em máquinas industriais, pontes, engenharia marítima e na fabricação de componentes estruturais pesados. A qualidade do corte afeta diretamente o desempenho estrutural de toda a máquina. O corte tradicional por chama é ineficiente e de baixa precisão, o corte por plasma apresenta fendas largas e zonas afetadas pelo calor extensas, enquanto o corte a laser único em chapas grossas é propenso à formação de sopros e acúmulo de escória, limitando a espessura e estabilidade do processo. A indústria necessita urgentemente de um novo processo de corte para chapas grossas que integre alta eficiência, alta precisão e baixo custo.

Corte Híbrido Laser-Chama: A Nova Tecnologia Principal para Corte de Chapas Grossas

Laser da DMK - a solução de corte híbrida combina a alta densidade de energia dos lasers com a forte capacidade de limpeza de escória das chamas, resolvendo dois grandes desafios no processamento de chapas grossas: "formação difícil do furo inicial" e "acúmulo de calor nos furos". Por exemplo, a perfuração de aço carbono de 100 mm leva apenas cerca de 8 segundos com o método híbrido, enquanto o corte tradicional a chama exige um longo tempo de pré-aquecimento, alcançando uma melhoria significativa na eficiência.

O modo híbrido pode cortar chapas extra-grossas até 200 mm, superando em muito o limite de 60 mm do corte a laser convencional, permitindo uma capacidade de processamento completa, desde chapas finas até chapas extra-grossas.

Melhoria Significativa na Eficiência de Corte de Chapas Grossas

Equipada com a cabeça de corte DMK BLTFX0 e sistema de controle 9100, a solução mantém alta velocidade de corte na faixa de espessura de 20–160 mm. Em comparação com os métodos híbridos de corte de concorrentes e métodos tradicionais a chama, a velocidade é geralmente aumentada em 30%–100%. Por exemplo:

Ambos são superiores às velocidades de processamento de equipamentos tradicionais. O sistema oferece funções como ignição automática, remoção automática de escória de perfuração e ajuste inteligente de parâmetros, reduzindo a intervenção manual e alcançando uma qualidade de processamento mais estável e um ritmo de corte mais rápido.

Equilíbrio timo entre Qualidade e Precisão no Corte de Chapas Grossas

Para resolver problemas comuns no corte de chapas grossas, como deformação, desvio de perpendicularidade e porosidade, o sistema possui múltiplas funções inteligentes de compensação:

Em termos de corte em bisel, o sistema suporta processamento de bisel ±45° V, X, Y e K, permitindo a conformação de biséis em um único passo. Isso reduz significativamente os processos de preparação pré-soldagem e melhora a eficiência de montagem dos componentes estruturais.

Otimização de Escaneamento e Aproveitamento de Material no Processamento de Chapas Grossas

As sobras de chapas grossas possuem formas complexas, o que dificulta a medição manual e resulta em baixa taxa de aproveitamento. Dmk's A tecnologia de escaneamento Sky Eye pode identificar automaticamente os contornos de sobras irregulares. Combinada com a função de aninhamento automático com um clique, aumenta a taxa de aproveitamento de sobras em mais de 175%, reduzindo efetivamente os custos de material.

No processamento de chanfro secundário, o sistema de digitalização pode realizar automaticamente posicionamento aproximado, digitalização precisa e compensação dimensional, alcançando uma precisão de posicionamento de ±0,3 mm. Isso melhora significativamente a qualidade do chanfro em componentes estruturais de chapas grossas e a precisão das juntas de soldagem.

Equilíbrio entre Custo e Eficiência no Corte de Chapas Grossas

A solução híbrida de corte da DMK pode atender simultaneamente às necessidades de corte a ar de alta velocidade para chapas médias e finas e ao processamento de alta qualidade de chapas grossas/extra-grossas. Um único conjunto de equipamentos substitui múltiplos processos e máquinas, reduzindo os custos de investimento e manutenção dos equipamentos. Além disso:

Essas vantagens conjuntamente reduzem o custo total de toda a cadeia de processamento.

Dmk's a tecnologia de corte híbrido laser-chama resolve efetivamente os problemas de "baixa eficiência, baixa precisão, formação fácil de poros e grande deformação" no processamento tradicional de chapas grossas, permitindo o corte eficiente e estável de materiais com espessuras variando de 1 a 200 mm. Com vantagens como compensação inteligente, perfuração rápida, chanfragem de alta qualidade e aproveitamento elevado no alojamento das peças, esta solução tornou-se a tendência técnica central no campo do processamento de chapas grossas e extra-grossas.