- Strona Główna

- Produkty

- O Nas

- Wideo

- Aplikacja

- Aktualności

- Centrum Pomocy

- Skontaktuj się z nami

Gdy mówimy o spawaniu metali, wielu ludzi nadal wyobraża sobie sceny iskier latających podczas spawania elektrycznego. Powoduje ono nie tylko znaczną deformację elementów i chropowate złącza spawane, ale także nie radzi sobie z potrzebami przetwarzania precyzyjnych komponentów. Jednakże...

Skontaktuj się z nami

Gdy mówimy o spawaniu metali, wielu ludzi nadal wyobraża sobie sceny iskier latających podczas spawania elektrycznego. Powoduje ono nie tylko znaczną deformację elementów i chropowate złącza spawane, ale także nie radzi sobie z potrzebami przetwarzania precyzyjnych komponentów. Jednakże obecnie, technologia spawania laserowego dawno stało się kluczowym procesem w dziedzinach takich jak motoryzacja, medycyna i lotnictwo, dzięki swoim zaletom takim jak „precyzyjna kontrola temperatury, wysoka wydajność i niewielkie uszkodzenia”. W jaki sposób dokładnie pokonuje ono wąskie gardła tradycyjnego spawania? Jaki rodzaj sprzęt do spawania laserowego należy wybrać dla różnych scenariuszy? Dziś pomożemy Ci zrozumieć „kluczową logikę” spawania laserowego i przygotujemy poradnik doboru urządzeń odpowiednich do różnych potrzeb.

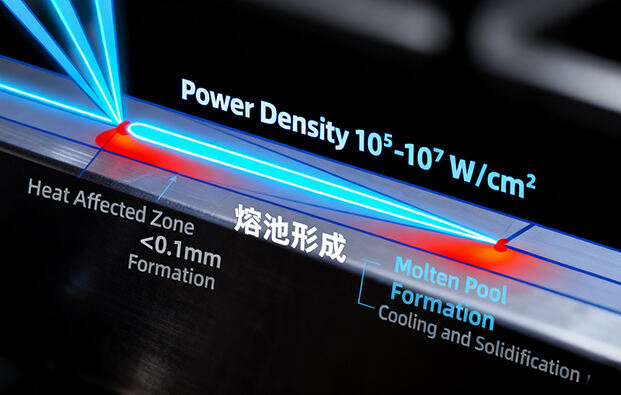

Główną zasadą działania spawanie laserowe właściwie nie jest skomplikowane. Mówiąc prosto, wykorzystuje ono wiązkę laserową o dużej gęstości mocy (gęstość mocy może wynosić nawet 10⁵∼10⁷ W/cm²) jako źródło ciepła. Ta wiązka laserowa jest skupiana na powierzchni metalu, nagrzewając lokalnie obszar do stanu stopionego i tworząc kałużę spawalniczą. Gdy wiązka laserowa przesunie się dalej, kałuża szybko ostyga i krzepnie, umożliwiając połączenie dwóch kawałków metalu w trwałe wiązanie metalurgiczne.

W porównaniu z tradycyjnym spawaniem łukowym i spawaniem gazowym jego zalety są wyraźnie widoczne. Strefa wpływu ciepła jest bardzo mała, a odkształcenie elementu może być kontrolowane na poziomie 0,1 mm, co czyni je szczególnie odpowiednim do zastosowań wymagających wysokiej precyzji. Wydajność spawania jest 3–5 razy większa niż w tradycyjnych procesach. Na przykład przy spawaniu stali nierdzewnej o grubości 2 mm laserem o mocy 2 kW prędkość spawania może osiągnąć 3,5 m/min. Nawet trudno spawalne materiały, takie jak stopy tytanu, stopy aluminium czy superstopy, mogą być łatwo przetwarzane metodą spawania laserowego. Umożliwia ono nawet niezawodne łączenie metali różnorodnych, takich jak miedź–stal czy aluminium–stal, co jest kluczową przyczyną szybkiego przeboju tej technologii na rynku wytwarzania wysokiej klasy.

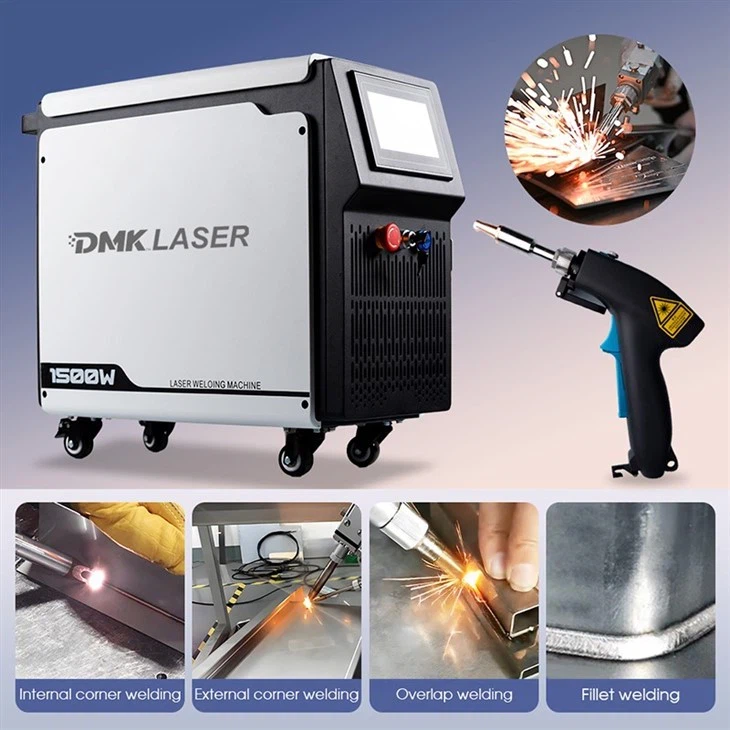

Spawanie laserowe nie jest rozwiązaniem uniwersalnym sprzęt do spawania laserowego jest bardzo odpowiedni do różnych zastosowań. Wybór odpowiedniego wyposażenia nie tylko zapewnia jakość, ale także pozwala uniknąć marnotrawstwa kosztów. Obecnie w przemyśle powszechnie stosuje się trzy główne typy laserów: Laserów CO2 Laserów stałych YAG , oraz lasery włókniste .

Urządzenia do spawania laserowego CO2 skupia się na spawaniu blach średnich i grubych. Posiada długość fali wyjściowej 10,6 μm oraz moc dochodzącą do 20 kW. W przypadku elementów konstrukcyjnych ze stali węglowej i nierdzewnej o grubości 3–20 mm stosowanych w budowie statków i maszyn budowlanych umożliwia jednoprzebiegowe spawanie pełnopenetracyjne, przy współczynniku głębokości do szerokości szwu wynoszącym 5:1. przemysłowy aparat do spawania laserowego CO2 który sprzedajemy, wyposażony w stół CNC, może obsługiwać duże przedmioty o wymiarach 6 m × 2,5 m i umożliwia monitorowanie pozycji plamki w czasie rzeczywistym, co czyni go idealnym rozwiązaniem do seryjnej produkcji ram samochodowych i zbiorników pod ciśnieniem.

Urządzenie do spawania laserowego YAG o stanie stałym jest "ekspertem" w dziedzinie precyzyjnych małych elementów. Dzięki długości fali 1,06 μm, która może być przesyłana przez włókna optyczne, może spawać stalowe druty o średnicy 0,1 mm, a dokładność miejsca spawania może osiągnąć ±0,01 mm. Nasz przenośny zgrzewarka laserowa YAG ma niewielkie rozmiary, nadaje się do konserwacji urządzeń medycznych i naprawy komponentów elektronicznych, a nawet do obsługi małych końcówek na płytach głównych telefonów komórkowych.

Urządzenia do spawania laserowego wątkowego dobrze radzi sobie z materiałami o wysokiej refleksyjności, takimi jak stopy aluminium i miedzi. Posiada wysoką jakość wiązki (czynnik M2 bliski 1). Podczas spawania stopów aluminium o grubości 3 mm nie powstają pustki. W połączeniu z robotem może realizować spawanie 3D. Nasz system spawalniczy z wysoką mocą światła laserowego od 1 do 6 kW jest już szeroko stosowany w linii produkcyjnej podłużnic baterii pojazdów nowej energii, cechuje się wysoką wydajnością i niskim współczynnikiem braku.

Obecnie spawanie laserowe od dawna stało się częścią naszego życia i jest wspierane przez odpowiednie sprzęt do spawania laserowego w tle. W produkcji samochodów, blachy karoseryjne ze stali nierdzewnej i wysokowytrzymałej stali ocynkowanej wykorzystują urządzenia do spawania laserowego CO2, aby osiągnąć dużą wytrzymałość i lekką konstrukcję. W medycynie, powłoki tytanowe implantów zębowych i rozruszników serca muszą być wykonywane przy użyciu Urządzeń do spawania laserowego YAG aby zapewnić „brak odkształceń i brak zanieczyszczeń”. W przemyśle lotniczym, centralny kołnierz dużego samolotu C919 oraz łopatki turbin silników lotniczych opierają się na wysokomocnych urządzeniach do spawania włóknem laserowym, aby zagwarantować niezawodność w warunkach wysokiego ciśnienia i temperatury.

Podczas doboru wyposażenia nie ma potrzeby ślepego dążenia do wysokiej mocy. Kluczowe są trzy aspekty: dopasowanie mocy do grubości materiału (1–2 kW dla cienkich płyt, 3–6 kW dla płyt średnich i grubych oraz powyżej 10 kW dla bardzo grubych płyt), dopasowanie jakości wiązki do wymagań dokładności (M2<1,5 dla precyzyjnych elementów i M2<3 dla zwykłych części) oraz dopasowanie konfiguracji automatyzacji do trybu produkcji (kompletne zestawy CNC do masowej produkcji i przenośne urządzenia do napraw w małej serii). Na przykład, dwukilowatowy włóknowy laser do spawania nadaje się do produkcji stali nierdzewnej naczyń kuchennych, podczas gdy sześciokilowatowy system spawalniczy z laserem włóknowym z platformą CNC 3D jest odpowiedni do produkcji elementów lotniczych i kosmicznych.

Dzięki modernizacji technologicznej, spawanie laserowe nadal rozwija się w kierunku większej inteligentności i wydajności. „Spawanie hybrydowe laserowo-łukowe” pozwala zwiększyć głębokość wnikania wiązki i zmniejsza wymagania montażowe. Urządzenia z „wizyjnym monitorowaniem AI” mogą dostosowywać parametry w czasie rzeczywistym i ograniczać konieczność ingerencji człowieka. W przyszłości, w miarę jak koszt sprzęt do spawania laserowego stopniowo będzie obniżany, nie tylko będzie się pogłębiać jego obecność w branży zaawansowanej produkcji, ale również przeniknie do większej liczby małych i średnich przedsiębiorstw, całkowicie zmieniając ekstensywne metody tradycyjnego spawania. Jeśli nadal wahasz się przy wyborze urządzenia, skontaktuj się z nami. Możemy stworzyć spersonalizowane rozwiązanie w zakresie spawania laserowego, oferując pełen wsparcie – od doboru sprzętu po szkolenia serwisowe – pomagając Ci rozwiązać problemy produkcyjne i poprawić konkurencyjność produktu odpowiednim wyposażeniem.