DMK SLM 200W 500W GT260 Metaal 3D-printsysteem

Productomschrijving

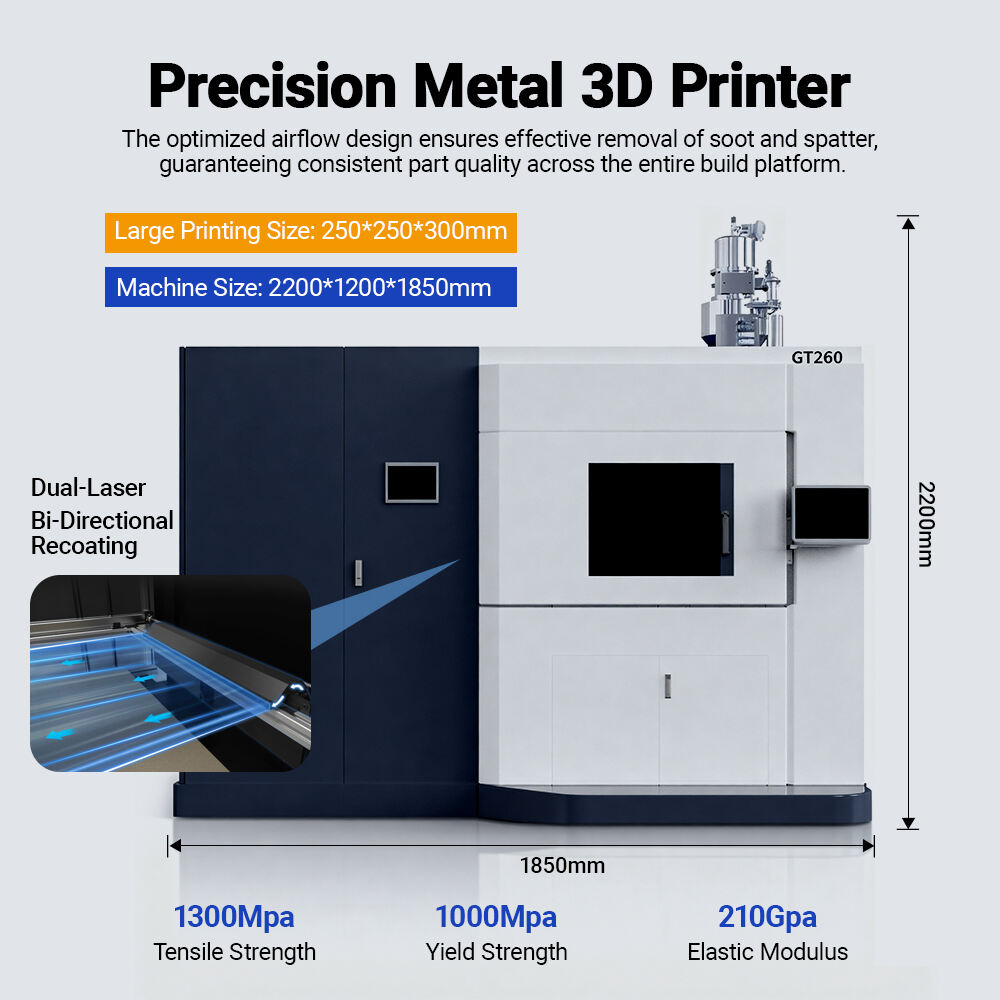

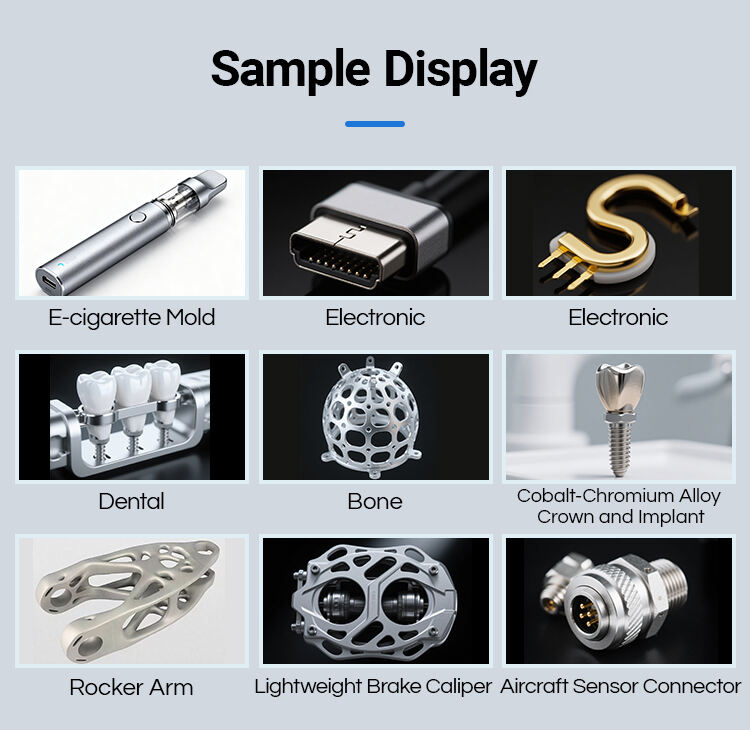

De GT260 Metaal 3D-printsysteem is een hoogwaardige additieve productieoplossing op basis van powder bed fusion (PBF) technologie. Door gebruik te maken van fijne metalen poeders en geavanceerde lasersystemen, zet het digitale 3D-modelgegevens om in hoogwaardige metalen onderdelen door materiaal selectief laag voor laag te smelten. De GT260 combineert digitale productie, geavanceerde materialen en intelligente software, waardoor het een essentieel hulpmiddel is voor moderne industrieën die Industry 4.0 omarmen.

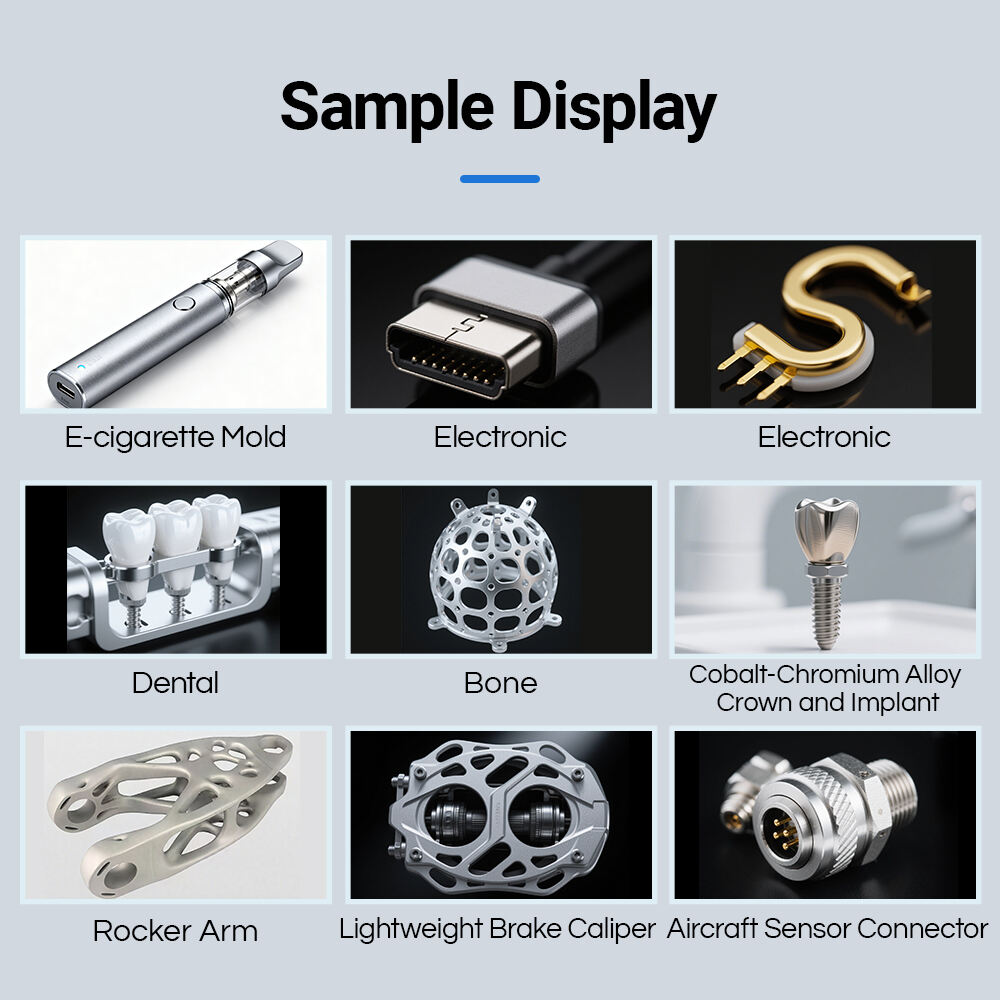

Gebaseerd op moderne CAD/CAM-, CNC- en laserbewerkingstechnologieën is de GT260 ideaal voor de productie van complexe geometrieën, functionele onderdelen en prototypen in sectoren zoals lucht- en ruimtevaart, automobiel, medisch, tandheelkundig, sieraden, onderwijs , en meer.

Productparameters

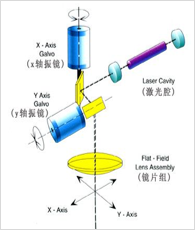

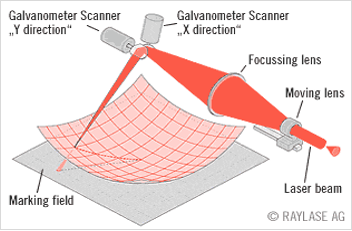

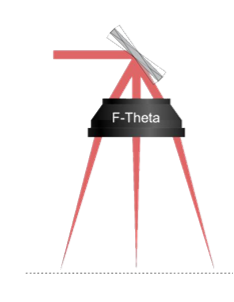

SLM-optisch systeem

veldspiegel

De rol van de 3D-geprinte veldspiegel is om kromming om te zetten in platheid, waarbij een bolvormig oppervlak wordt omgezet in een plat oppervlak zoals vereist door het apparaat.

|

|

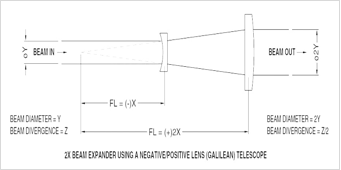

Bundelverbreder / Scanspiegel

|

Bundelverbreder |

Scanspiegel |

Andere gegevens

Ondersteuning van meerdere materialen

Compatibel met roestvrij staal, gereedschapsstaal, kobalt-chroom, hittebestendige legeringen, titaan en aluminiumlegeringen.

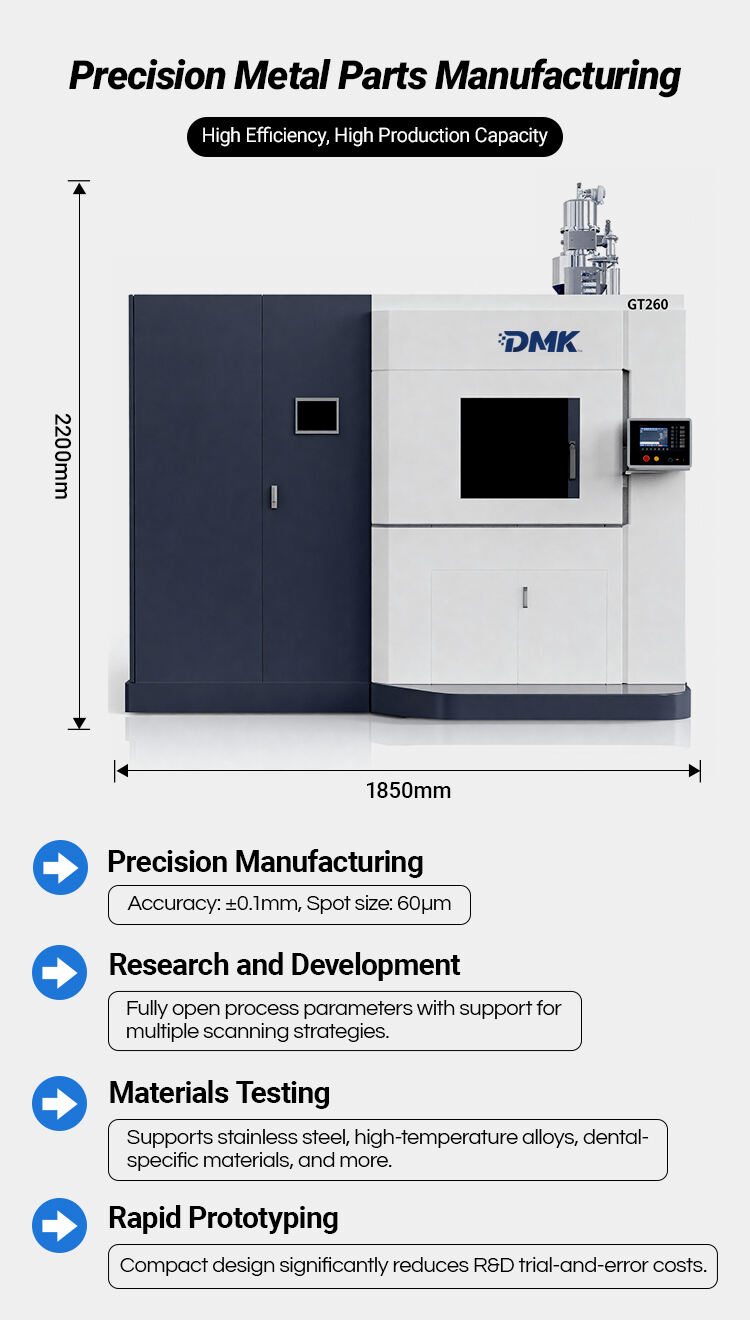

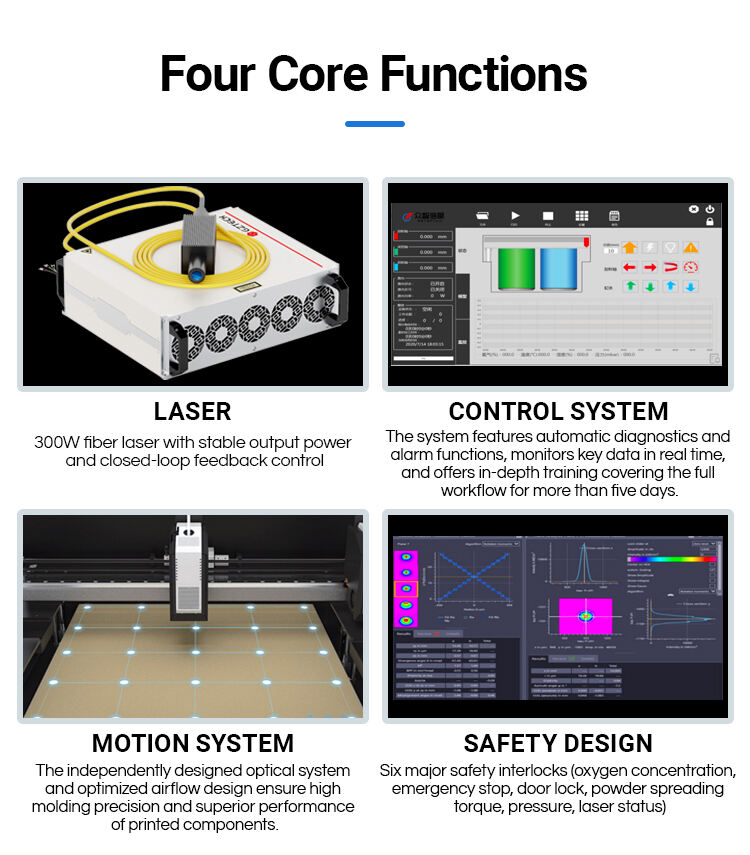

Hoge precisiedruk

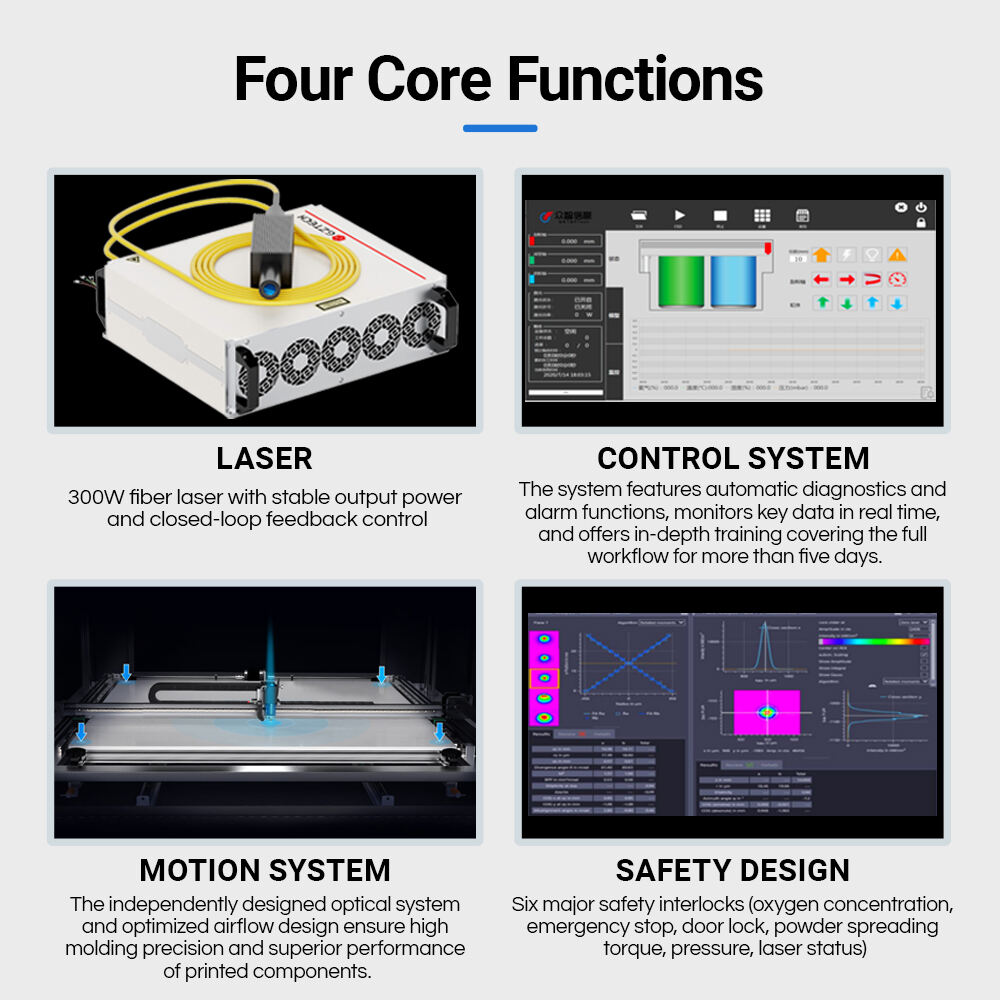

Beschikt over een zelfstandig ontwikkeld optisch padsysteem en een geoptimaliseerd luchtvloedontwerp om hoge nauwkeurigheid en prestaties van onderdelen te garanderen.

Efficiënte Materialenafhandeling

Past een poedercilindersysteem toe voor een vlotte materiaaltoevoer en consistente laagopbouw.

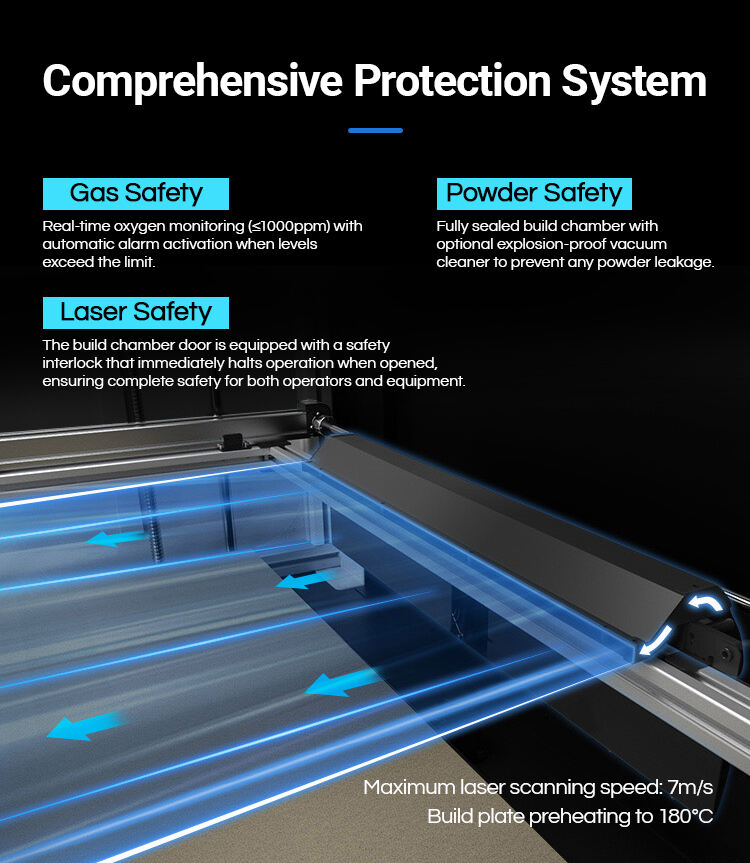

Geoptimaliseerde luchtvloei & stofafvoer

Ontworpen voor schone werking met een dubbel filtersysteem en effectieve rook- en spattersafvoer, zelfs tijdens het printen van volledige oppervlakken.

Open materiaalsysteem

Ondersteunt een breed scala aan materialen en staat configuratie toe van aangepaste procesparameterpakketten.

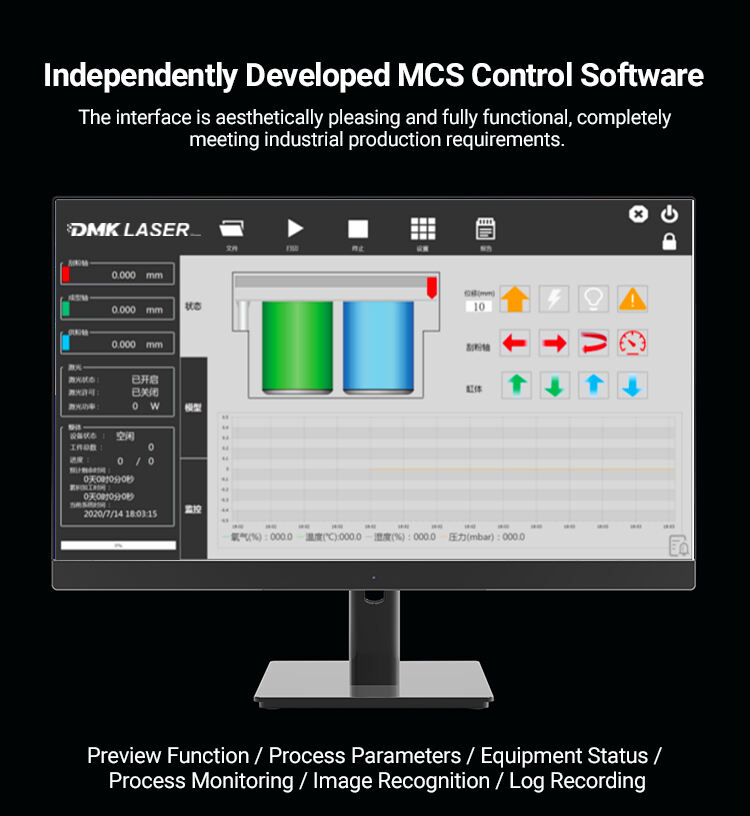

Intelligente Procesbewaking

Registreert automatisch gedetailleerde logboeken tijdens het gehele printproces, inclusief aantal lagen, onderdeeltemperatuur, kamerdruk, zuurstofconcentratie en meer – voor traceerbaarheid en consistente onderdelenkwaliteit.

Gebruiksvriendelijke Interface

Intuïtief gevisualiseerd bediensysteem met mensgerichte ontwerpfilosofie voor gebruiksgemak en onderhoud.

Geavanceerde slicingsoftware

Uitgerust met Magics + BP en 3DXpert, waardoor flexibele datatoevoer en efficiënte baanplanning mogelijk zijn.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR