DCL-1500W/2000W-A Hoogvermogen luchtkoelde continue laserreinigingsmachine - 1500W/2000W instelbaar + meerdere scanpatronen + 10 m glasvezel + 65 kg draagbaar - Voor reiniging in lucht- en ruimtevaart/spoorvervoer/industriële zware vervuiling

Productomschrijving

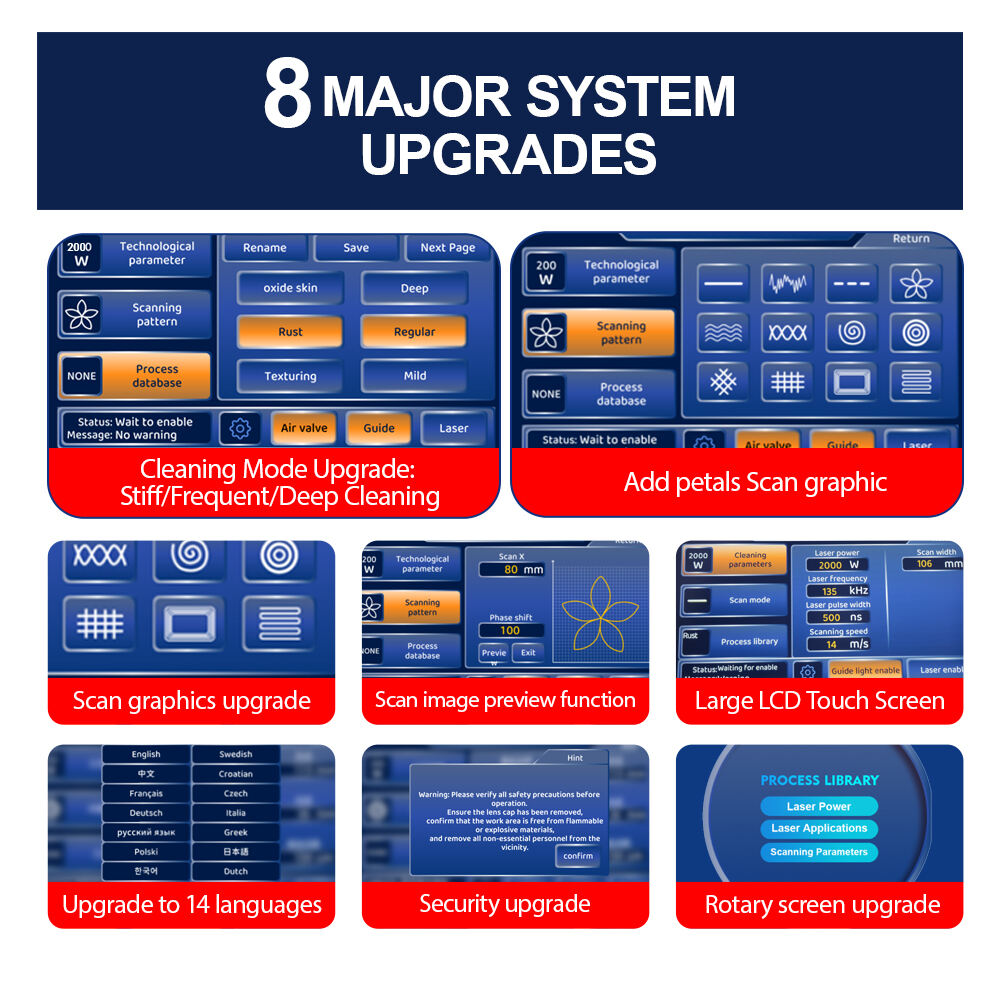

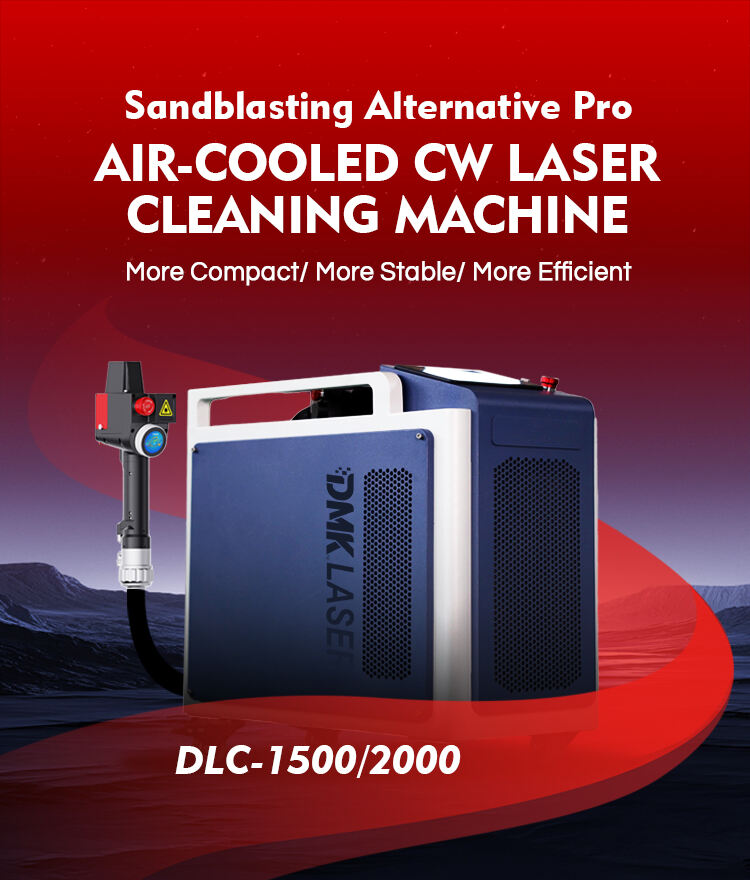

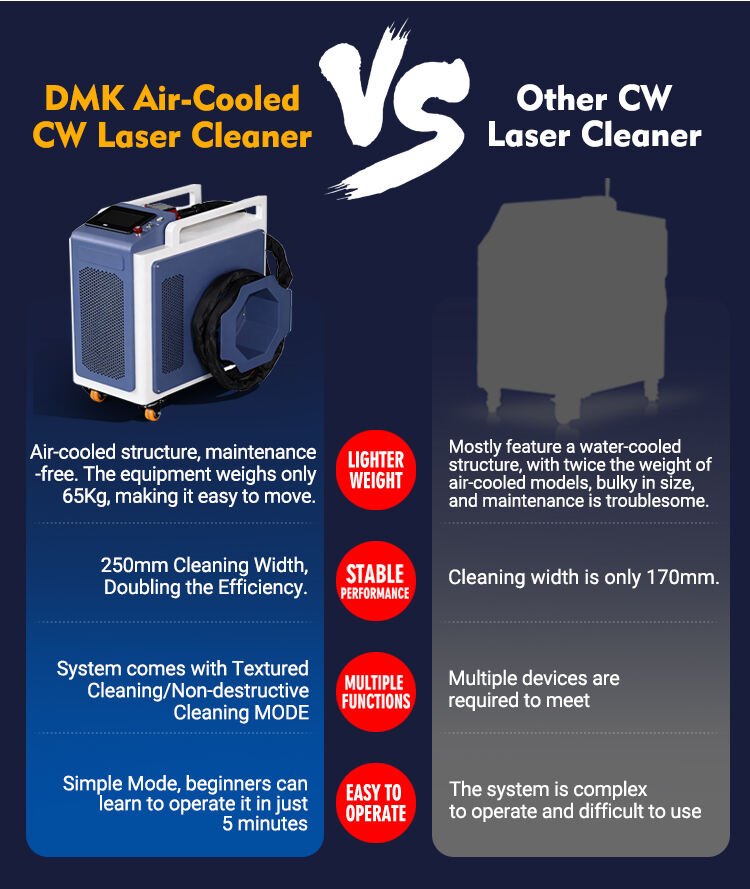

DCL-1500W/2000W-A is een professionele hoogvermogen luchtgekoelde continue laser Reinigingsmachine ontworpen voor industriële toepassingen met zware vervuiling. Met gebruikmaking van een continu vezellaser van een gerenommeerd binnenlands bedrijf, een hoogwaardig scansysteem, een hoogwaardig precisiesturingssysteem en een voeding van een wereldwijd bekend merk, is de machine stabiel en betrouwbaar met uitstekende prestaties, hoge efficiëntie en een uitstekende prijs-kwaliteitverhouding.

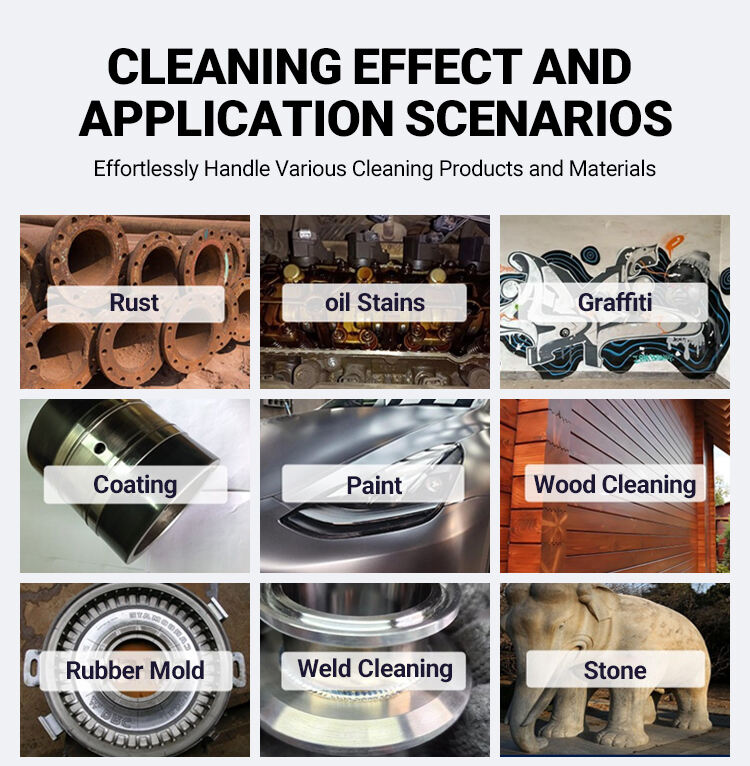

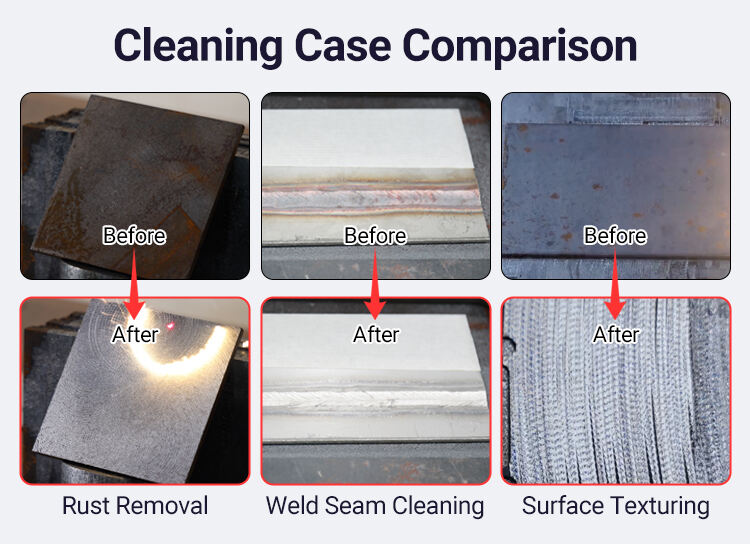

Deze apparatuur kan op efficiënte wijze roest, verf, olievlekken van metalen en gedeeltelijk niet-metalen oppervlakken verwijderen, evenals zwarte as, koolstofafzettingen en olieverontreiniging op componentoppervlakken na laswerkzaamheden. In vergelijking met traditionele reinigingsmethoden biedt deze industriële laserreinigingsapparatuur duidelijke voordelen: contactloze reiniging zonder het substraat te beschadigen, milieuvriendelijk zonder secundaire vervuiling, micronnauwkeurige precisiebesturing (in dikterichting), geen verbruiksmaterialen tijdens gebruik (alleen stroomverbruik) en een hoge mate van toepasbaarheid.

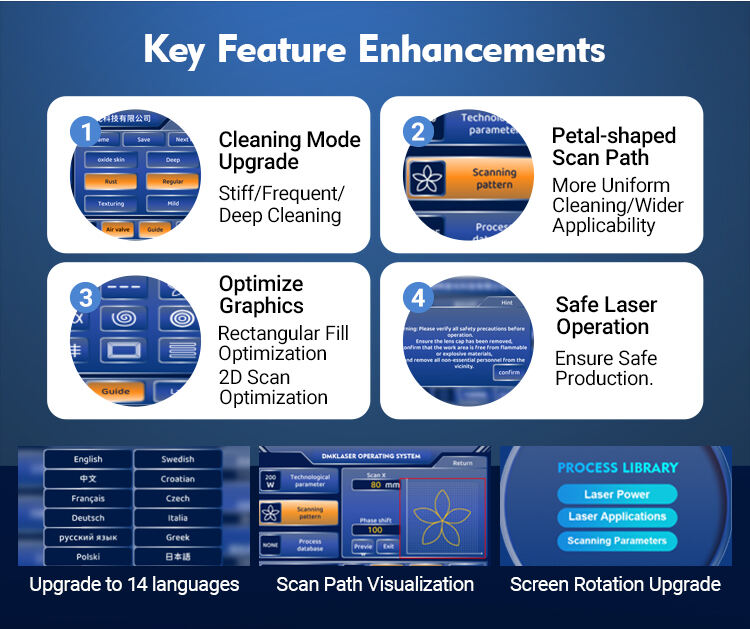

Met een netto gewicht van 65 kg en universele wielen is het gemakkelijk te verplaatsen. Het handbediende reinigingshoofd weegt slechts 1,8 kg, waardoor het gebruik licht en handig is. Voorzien van meerdere scanpatronen kan het zich aanpassen aan complexe werkomstandigheden en de reinigingswerking garanderen. Door het luchtkoelontwerp en de 10 meter lange vezel wordt het toepassingsbereik uitgebreid, geschikt voor zowel handbediening als integratie in geautomatiseerde systemen. Het wordt veel gebruikt in de lucht- en ruimtevaart, railvervoer, automobielindustrie, scheepsbouw, matrijzenbewerking en andere sectoren, met name geschikt voor industriële zware vervuilingreiniging en reiniging van complexe werkstukken.

Productparameters

| Parameter Categorie | Specifieke parameters |

|---|---|

| Optische kenmerkparameters | - Gemiddeld laser vermogen: 1500W/2000W - Centrale golflengte: 1080 nm - Vermogensregelbereik: 10%~100% instelbaar - Laserpulsfrequentie: 0 kHz~5 kHz instelbaar - Laserlijnbreedte: 5 mm~300 mm (F400); 5 mm~400 mm (F600); 5 mm~500 mm (F800) - Vezellengte: 10 m - Minimale buigradius van de glasvezel: 200 mm - Koelmodus: Luchtkoeling - Polariseringsrichting: Willekeurig - Geleide laserfunctie: Beschikbaar - Anti-hyperreflexie: Beschikbaar - Veldspiegelmodel: F400/F600/F800 (optioneel) - Instabiliteit van laseruitgang: <5% |

| Algemene kenmerkende parameters | - Netto gewicht: 65 kg - Gewicht reinigingskop: 1,8 kg - Afmetingen krat: L715 mm × B520 mm × H744 mm (afhankelijk van de daadwerkelijke levering) - Bedieningswijze: Handbediend - Voedingsspanning: AC 220±10% V - Netfrequentie: 50 Hz - Bedrijfstemperatuurbereik: 0 ℃ ~ 40 ℃ - Opbergtemperatuurbereik: -10 ℃ ~ 60 ℃ - Stroomverbruik @25 ℃: <8 kW (DCL-1500 W); <10 kW (DCL-2000 W) - Aanvoerluchtdruk: ≥0,6 MPa (olievrije en watervrije schone perslucht) |

Andere gegevens

1. Configuratie

| Configuratietype | Details |

|---|---|

| Standaardconfiguratie | - Reinigingshoofdapparaat: 7-inch beeldscherm, B-serie reinigingskop, 10 m bedieningskabel, laserindicator rood licht, extern bedieningsinterface - Laserbeschermbril: 1 paar (voldoet aan EU EN207:2009/AC2011 & CE-certificering, beschermingsband 190~400 nm & 800~1100 nm) - Vervangbare beschermrand: 5 stuks - Gebruiksaanwijzing: 1 exemplaar - Garantie: 1 jaar |

2. Veiligheid & Bediening

- De uitrusting is een laserproduct van klasse IV. Direct, verstrooid of indirect contact met de laser kan huidverbranding veroorzaken en blijvend oogletsel tot gevolg hebben. Bedieners moeten tijdens het gebruik altijd de meegeleverde laserbeschermbril dragen.

- Noodstopknoppen: Twee rode paddenstoelvormige knoppen, respectievelijk geplaatst aan de rechterkant van het bedieningsgebied van het chassis en op de reinigingskop. Druk onmiddellijk op de knop bij anomalieën, en draai deze rechtsom om te resetten.

- Bedieningsstappen: Stroom inschakelen → Voer wachtwoord "3214" in om te ontgrendelen → Pas procesparameters aan (laser vermogen, frequentie, scansnelheid, enz.) → Selecteer scanpatroon → Activeer de laser om te beginnen met reinigen.

- Belangrijke voorzorgsmaatregelen: Zorg ervoor dat de buigradius van de glasvezel >200 mm is; houd een ventilatieafstand van 10 cm rondom het apparaat; plaats geen ontvlambare of explosieve materialen in de buurt; dek de laseruitgang met een beschermkap wanneer deze niet in gebruik is.

3. Onderhoud & Probleemoplossing

| Dagelijks onderhoud | Gemeenschappelijke probleemoplossing |

|---|---|

| - Reinig de lens van het reinigingshoofd regelmatig met speciale gereedschappen om stofverontreiniging te voorkomen. | - Geen stroom aanwezig: Controleer of de noodstopknop is gereset, de stroomaansluiting en de stand van de stroomonderbreker. |

| - Controleer de glasvezel- en bedieningskabel op slijtage of breuk vóór elk gebruik. | - Geen rood licht: Verwijder de beschermkap van de veldspiegel; controleer of de lens van het reinigingshoofd kapot is. |

| - Houd het apparaat schoon en droog, vermijd contact met water of corrosieve stoffen. | - Geen laseruitgang: Controleer of de voeding, de sleutelschakelaar en de laserschakelaar zijn ingeschakeld; controleer of de focuspositie is verschoven. |

| - Het apparaat moet worden onderhouden door gekwalificeerd personeel; demonteer het niet zelf. | - Zwakke laseruitgang: Reinig de veldspiegel; stel de focuspositie af op het juiste bereik. |

Monsterscherm

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR