When it comes to 3D printing, you may have seen plastic toys or resin figurines, but did you know that even titanium alloy components for aerospace and customized dental implants in the medical field can now be printed in one go with "lasers"? Behind...

Contact Us

When it comes to 3D printing, you may have seen plastic toys or resin figurines, but did you know that even titanium alloy components for aerospace and customized dental implants in the medical field can now be printed in one go with "lasers"? Behind this lies the core power of high-power fiber lasers. Why can they become the "core engine" of metal 3D printing? And how do they balance high power and high precision? Today, let's explore the integrated world of fiber lasers and 3D printing, breaking down the key technologies.

I. Fiber Laser + 3D Printing: Redefining Metal Part Manufacturing

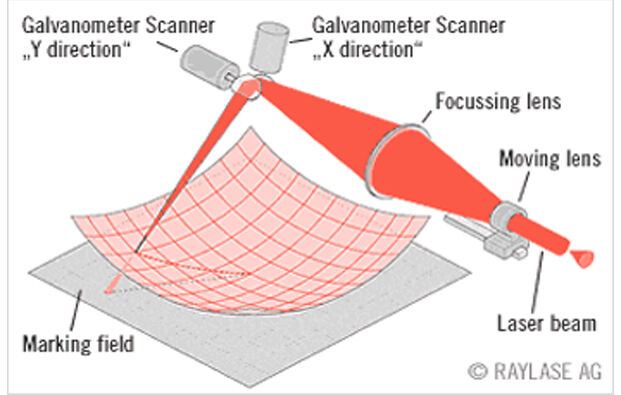

Traditional metal processing relies on molds and cutting. Complex structures often require multiple assembly steps, which are time-consuming and result in significant material waste (material utilization in traditional cutting is less than 30%). Fiber laser 3D printing (represented by Selective Laser Melting, SLM) completely subverts this model-it uses metal powder as raw material, and a high-power fiber laser melts the powder layer by layer along a preset path. After cooling, the layers stack into a three-dimensional part. The entire process requires no molds, similar to "drawing with light on metal powder, laying new powder after each layer, and stacking up to form the finished product."

The advantages of this technology are supported by high-power fiber lasers: they output laser beams of extremely high quality, with small divergence angles and uniform spots (minimum spot size up to 0.1mm), enabling precise reproduction of fine part structures, such as complex flow channels in turbine blades or precision teeth in gears. Meanwhile, their power is controllable over a wide range (from hundreds of watts to several kilowatts), capable of handling metal sheets as thin as 0.1mm and melting stainless steel plates as thick as 50mm. More importantly, fiber lasers have an electro-optical conversion efficiency of 25%-30%, with heat dissipation far exceeding traditional YAG lasers. Even long printing sessions won't affect precision due to overheating, making them ideal for aerospace, medical, and other fields with strict part quality requirements.

II. From Lab to Industry: Real-World Applications of Fiber Laser 3D Printing

Today, fiber laser 3D printing has moved from technical concept to multiple high-end fields, solving challenges that traditional processing could not overcome, and emerging as a "new tool" for high-end manufacturing.

In aerospace, Beihang University used fiber laser 3D printing to produce large titanium alloy main load-bearing components for aircraft, reducing part weight by 30% while increasing strength by 15%. Northwestern Polytechnical University even printed the central wing flange for China's C919 large aircraft, breaking foreign technological monopolies and freeing Chinese aviation manufacturing from reliance on imported molds.

In healthcare, customized dental implants and artificial joints can be "manufactured on demand" via fiber laser 3D printing. Based on a patient's CT data, the laser precisely controls the melting range of titanium alloy powder, ensuring the implant fits perfectly with the alveolar bone, reducing surgical risks and shortening treatment cycles (traditional custom implants take 1 month, while laser 3D printing takes only 3 days).

In automotive manufacturing, traditional processes cannot create complex internal structures for engine cylinder head cooling channels, but fiber laser 3D printing forms them in one go, improving cooling efficiency by 20%, reducing part weight, and helping vehicles achieve lightweight design to lower energy consumption.

III. Future Outlook: Fiber Laser 3D Printing Will Grow Even "Stronger"

Currently, high-power fiber lasers can achieve 2kW continuous output from a single fiber, and multi-fiber bundling technology can exceed 10kW. Future upgrades will focus on two directions:

On one hand, higher precision-combined with photonic crystal fiber technology, laser spots can be further reduced to 0.05mm, enabling printing of micro-scale parts like vascular stents to meet more refined medical needs.

On the other hand, lower costs-with technological breakthroughs in domestic double-clad fibers and semiconductor pump sources, fiber laser manufacturing costs are declining. They are expected to enter more small and medium-sized manufacturers, shifting metal 3D printing from "high-end customization" to "mass production," such as rapid manufacturing and repair of auto parts and molds.

From large aerospace components to tiny medical implants, high-power fiber lasers are redefining how metal parts are manufactured. They not only make processing complex structures more efficient and precise but also drive manufacturing toward "green and customized" development. In the future, we can expect more "fiber laser-printed" metal parts in daily life-customized automotive brake pads, household hardware, and even personalized metal jewelry.