When 3D printing is mentioned, plastic toys and resin models may come to mind first. But did you know that there is a type of laser 3D printing technology capable of directly "printing" metal parts such as titanium alloys and stainless stee...

Contact Us

When 3D printing is mentioned, plastic toys and resin models may come to mind first. But did you know that there is a type of laser 3D printing technology capable of directly "printing" metal parts such as titanium alloys and stainless steel, and even complex load-bearing components for the aerospace field? This is the Selective Laser Melting (SLM) 3D printing technology. What enables this technology to overcome the challenges of metal processing? And why has it become a "new tool" for high-end manufacturing? Today, we will break down the technical details behind it.

Selective Laser Melting (SLM) 3D Printing: Creating Metal Parts via "Laser-Melted Powder"

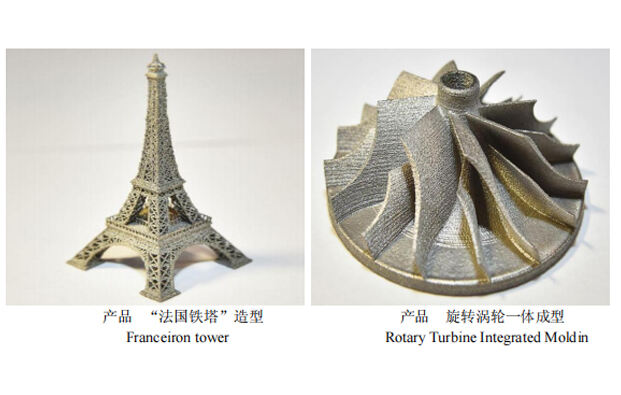

Unlike the common Fused Deposition Modeling (FDM) 3D printing, SLM 3D printing uses metal powder as raw material. A high-energy laser beam melts the powder layer by layer according to a preset path, and the melted powder cools and stacks to form a three-dimensional part. The entire process is like "drawing" on metal powder with a laser-after finishing one layer, a new layer of powder is spread, and layers are stacked to form the final product. It enables the integrated forming of complex structures without the need for molds, making it particularly suitable for special-shaped parts and hollow parts that are difficult to process with traditional cutting methods.

Uncovering the "Heart" of the Equipment: Core Structures That Determine Printing Precision

To achieve high-precision printing of metal parts, the core structures of the equipment are indispensable. According to research by the team led by Zhu Tianguang from Shenyang Ligong University, a professional SLM 3D printing equipment for metals mainly relies on three "key components" to ensure its performance:

Metal parts are "grown" layer by layer. After printing each layer, the workbench needs to drop precisely by the thickness of one layer (usually 0.02-0.1mm), which requires a precision Z-axis lifting mechanism for control. The research adopts a combined design of "servo motor + ball screw + linear guide rail". The motor is of the Delta ECMA-CA06 model, the screw has a diameter of 16mm, and the guide rail is of the SSR20XV type. This design can achieve a repeat positioning accuracy of ±0.001mm-equivalent to 1/60 of the diameter of a human hair-ensuring minimal error in layer stacking and preventing "step lines" on the parts.

Metal powder is prone to oxidation by oxygen in the air when melted at high temperatures, leading to pores and cracks in the parts. The inert gas protection chamber of the equipment first evacuates the air (to a vacuum degree of below 100Pa) and then fills it with inert gas such as argon. Through a cyclic purification system, the oxygen content is controlled within 100ppm (equivalent to only 0.1 liters of oxygen in 1 cubic meter of air), ensuring that the metal does not oxidize during melting and improving the mechanical strength of the parts.

The laser beam relies entirely on the optical galvanometer system to control its path for melting the powder. The system consists of two high-speed scanning galvanometers (X/Y axes). The motor drives the reflectors to deflect rapidly, allowing the laser beam to move on the powder surface like a "brush" at a scanning speed of several meters per second. Equipped with a fiber laser (which has high energy density and good heat dissipation), it can precisely control the spot size (minimum up to 0.1mm), easily realizing the printing of fine structures such as gear teeth and turbine blade flow channels.

From Laboratory to Factory: How Widely Is SLM Technology Applied in Practice?

Today, SLM 3D printing technology has moved from the laboratory to actual production and been applied in multiple high-end fields:

Aerospace Field: Northwestern Polytechnical University used SLM technology to manufacture the central wing flange of China's domestic large aircraft C919, reducing the part weight by 30% while increasing its strength by 15%. Beihang University (Beijing University of Aeronautics and Astronautics) even used it to print large titanium alloy main load-bearing components for aircraft, breaking the monopoly of foreign technology.

Medical Field: Customized dental implants and artificial joints can be "printed on demand" via SLM technology, fitting the patient's bone structure and reducing surgical risks. Titanium alloy plates used in orthopedic surgeries can also be designed with hollow structures through SLM, reducing the physical burden on patients.

Automotive Manufacturing Field: The team from Shanghai Jiao Tong University applied SLM technology to the research and development of auto parts, such as the cooling flow channels of engine cylinder heads. Traditional processes cannot form complex internal structures, but SLM can achieve one-time forming, improving the engine heat dissipation efficiency by more than 20%.

A Promising Future: What Bottlenecks Can SLM Technology Break Through Next?

With the advancement of Industry 4.0, SLM technology will also integrate with AI and digital twins. For example, AI can be used to optimize the laser scanning path and reduce internal stress of parts; digital twin technology can simulate the printing process and identify defects in advance. In the future, we may see more "customized metal parts" enter our lives-even your car brake pads and the faucet in your home may be "laser-printed"!