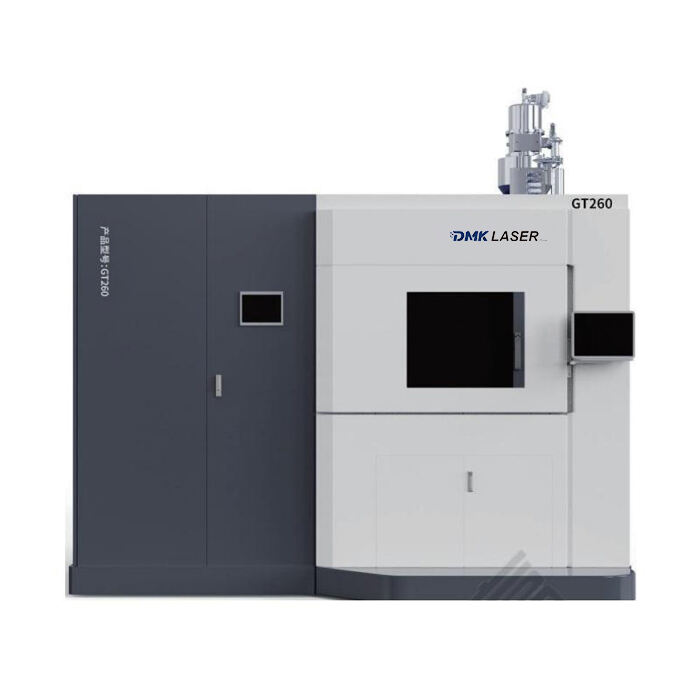

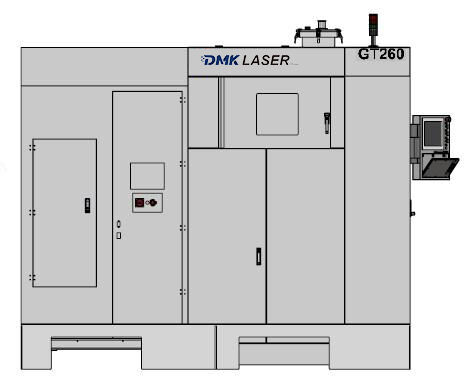

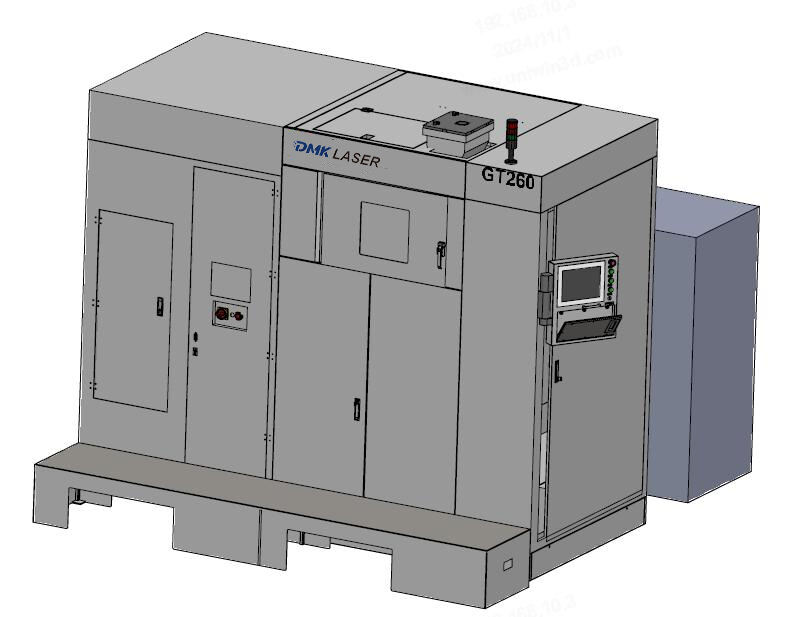

GT260 Metal 3D Printing Machine

Description

The GT260 Metal 3D Printer is an advanced metal additive manufacturing system based on powder bed fusion (PBF) technology. Utilizing high-performance metal powders and dual 500W lasers, it transforms 3D model data into high-precision parts through layer-by-layer laser sintering.

This system integrates digital manufacturing, materials engineering, and intelligent control technologies, making it an essential tool in modern smart manufacturing and digital economy development. It is widely used in industries requiring complex geometries, lightweight structures, and high material performance.

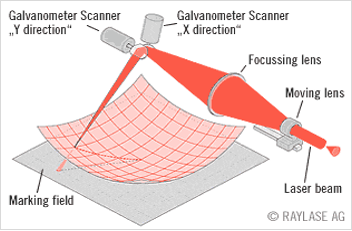

SLM optical system

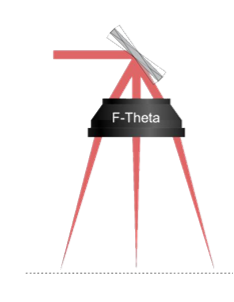

field mirror

The role of the 3D-printed field mirror is to transform curvature into flatness, converting a spherical surface into a flat surface as required by the device.

|

|

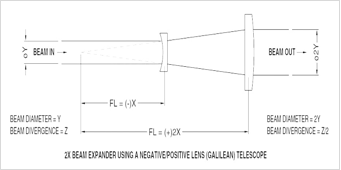

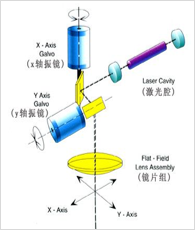

Beam expander /Scanner mirror

|

Beam expander |

Scanner mirror |

Key Features

Customizable Powder Coating System

Adaptable scraper material options based on different metal powders and part requirements.User-Friendly Interface

Intuitive, visual control system designed for easy operation and maintenance. Dual-filter system ensures process safety and environmental cleanliness.High Precision Forming

Proprietary optical path design and optimized airflow architecture ensure stable forming accuracy and superior part quality.Optimized Airflow & Debris Removal

Advanced fume and splatter control system maintains consistent build quality across the full print bed.Proprietary Process Software

In-house developed software intelligently optimizes scan paths to shorten production time.Open Material & Process System

Supports multi-material workflows with configurable process parameter packages.Full Build Log Recording

Automatically records detailed processing logs including layer count, part temperature, chamber pressure, oxygen levels, powder tank positions, and more—ensuring consistent, traceable quality control.

Core Advantages

High-Efficiency Dual Laser System: Increases build speed and supports complex part geometries.

Modular and Flexible Process Control: Compatible with various metal powders, including titanium alloys, stainless steel, cobalt-chrome, and more.

Industrial-Grade Design: Built for continuous production in demanding environments with a robust structural frame and stable printing performance.

Reliable and Repeatable: Automated data logging and precision components ensure consistency across batches.

Safe and Clean Operation: Dual filtration and inert gas protection (N₂/Ar) safeguard both operators and part quality.

Technical Specifications

| Parameter | Value |

|---|---|

| Device Size | 2200 × 1200 × 1850 mm |

| Max Build Volume | 250 × 250 × 300 mm |

| Forming Accuracy | ±0.05 mm |

| Powder Feeding Mode | Top/Bottom Powder Cylinder Feeding |

| Layer Thickness | 20–100 μm |

| Laser Power | 500W × 2 |

| Spot Diameter | 75 μm |

| Scanning Speed | 9 m/s |

| Forming Speed | 22–55 cm³/h |

| Oxygen Concentration | ≤100 ppm |

| Shielding Gas | Nitrogen (N₂) / Argon (Ar) |

| Power Consumption | 6 kW |

| Equipment Weight | 2100 kg |

| Software | Magics + BP, 3DXpert |

| Data Formats Supported | STL, OBL, STEP, etc. |

| Applicable Materials | Stainless steel, tool steel, cobalt-chrome alloy, superalloys, titanium alloys, aluminum alloys, and more |

The GT260 is suitable for both prototyping and direct part production in high-performance industries:

Aerospace & Defense: Structural and functional parts with lightweight and complex geometries.

Automotive: Customized components, lightweight structures, and rapid tooling.

Medical & Dental: Implants, surgical tools, and cobalt-chrome dental frameworks.

Mold & Die Making: Precision conformal cooling molds and inserts.

Consumer Electronics: Heat-dissipation components, brackets, and housings.

Education & R&D: Material and process development for academic institutions and innovation labs.

Case Showcase

|

Dentistry |

Medical |

|

Aviation Generators |

Mold Manufacturing |

|

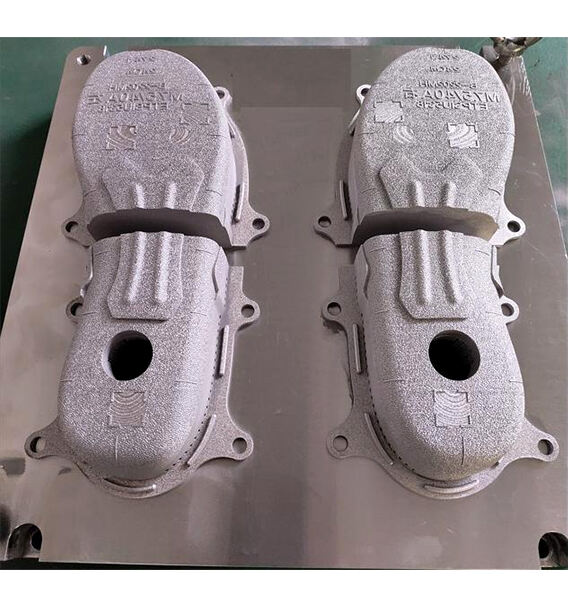

Shoe Molds |

Mold Manufacturing |

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR