Introduction: Why Surface Engineering Matters In demanding industries such as aerospace, petrochemicals, and marine engineering, over 80% of component failures are due to surface wear and corrosion. These failures not only reduce equipment service li...

Contact Us

In demanding industries such as aerospace, petrochemicals, and marine engineering, over 80% of component failures are due to surface wear and corrosion. These failures not only reduce equipment service life but also incur significant operational costs.

To counter these problems, various surface engineering techniques like electroplating, thermal spraying, vapor deposition, and laser cladding have been widely applied. Among them, Extreme High-Speed Laser Cladding (EHLA) stands out for its efficiency, precision, and eco-friendliness.

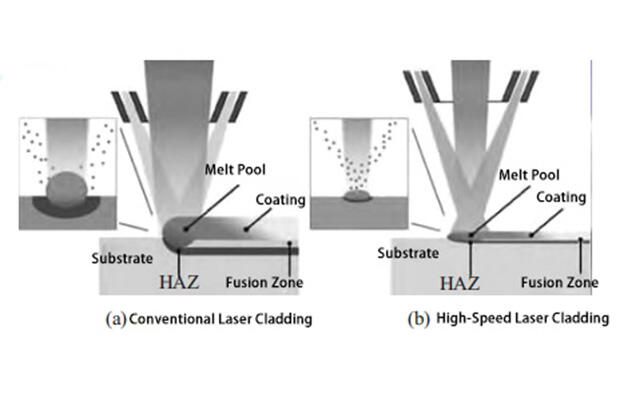

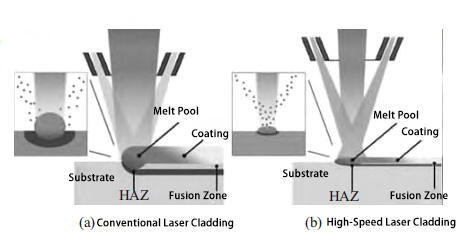

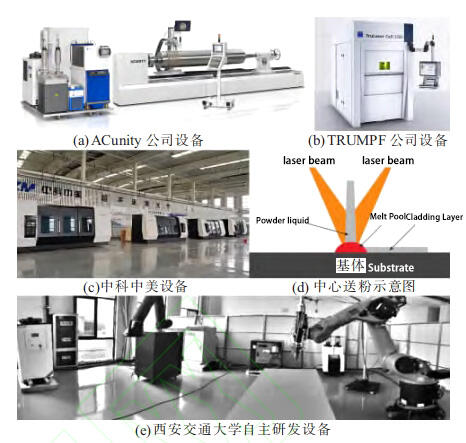

EHLA is an advancement over traditional laser cladding. It uses a high-power laser and coaxial powder feeding system to pre-melt coating material above the substrate, drastically increasing deposition speed while reducing thermal load and dilution.

Deposition speed: Up to 500 cm²/min, over 10x faster than traditional laser cladding

Surface quality: Ra < 10 μm, drastically reducing post-processing costs

Low dilution rate: <4%, preserving the performance of coating material

Fine microstructure: Faster cooling produces refined dendritic crystals

Minimal heat input: Ideal for thin-walled and large components

EHLA was pioneered by Germany's Fraunhofer Institute and later commercialized by companies like ACunity and TRUMPF.

In China, rapid progress has led to high-power cladding systems and optimized powder feeding heads, enabling up to 6 m²/h cladding efficiency for industrial use.

EHLA is compatible with a range of coating materials. Research primarily focuses on:

Iron-based alloys: Cost-effective, good wear/corrosion resistance.

Studies show significant grain refinement and property enhancement.

Cobalt-based alloys: Excellent high-temp wear resistance.

Fine microstructure achieved using EHLA shows potential for hydro turbines and molds.

Nickel-based alloys: Superior corrosion and oxidation resistance.

Ideal for applications in biomass boilers, where high-temperature stability is essential.

Amorphous alloys: EHLA enables >90% amorphous phase, solving prior brittleness and cracking issues.

High-entropy alloys: Improved service life with refined grains and stable phase formation at high scanning speeds.

Ceramic and composite coatings: Reinforced with WC, TiC, or CNTs for extreme wear and corrosion environments.

EHLA coatings have been successfully applied to:

Oilfield sucker rod couplings

Hydraulic supports in coal mining

Mold and roller protection

Boiler tube corrosion protection

Companies like Sinopec, China Coal Technology, and Yankuang Group have already integrated EHLA into production.

Despite rapid advances, EHLA still faces technical challenges:

Lack of dedicated powder systems: Most materials are adapted from thermal spray alloys.

Standardization: There's an urgent need for application-specific standards and performance benchmarks.

Hybrid processing: Combining EHLA with ultrasonic, electromagnetic, or mechanical post-treatment shows promise for improving coating quality.

Extreme High-Speed Laser Cladding is revolutionizing the field of surface engineering. With superior coating quality, high efficiency, and eco-friendly processing, EHLA stands as a strong candidate to replace conventional technologies like hard chrome plating. As material systems and equipment mature, EHLA will see broader adoption in industries where reliability under harsh conditions is critical.