In today's fast-paced home and commercial furniture industries, product quality and visual appeal are key. Stainless steel cabinets, especially those made from SUS304, are prized for their durability and sleek appearance. However, the welding process...

Contact Us

In today's fast-paced home and commercial furniture industries, product quality and visual appeal are key. Stainless steel cabinets, especially those made from SUS304, are prized for their durability and sleek appearance. However, the welding process used in assembling these cabinets plays a vital role in the final product’s performance and finish.

Traditional welding often struggles with deformation, uneven seams, and inefficiency. That’s where multi-wavelength composite laser welding comes in — a powerful new solution that enhances precision and weld quality while minimizing damage and visual defects.

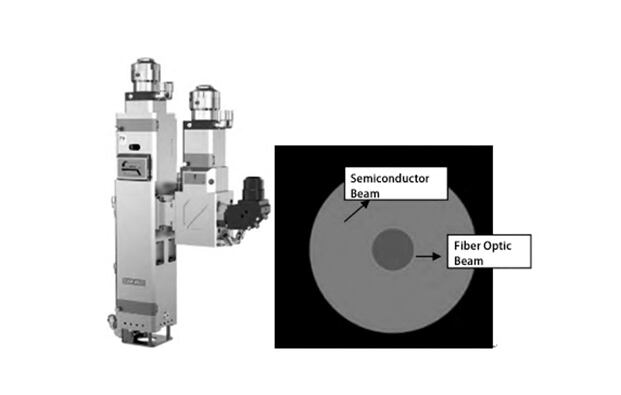

Laser welding, known for its high energy density and minimal thermal deformation, is already a popular choice in metalworking. This study explores a novel approach: combining 915nm semiconductor lasers and 1070nm fiber lasers to weld stainless steel cabinets. The results are promising — deeper, wider, cleaner welds and improved mechanical strength.

By using both a semiconductor and fiber laser simultaneously, the welding process promotes a more stable and dynamic molten pool. This dual-laser approach:

Increases fluidity

Promotes the rise of trapped bubbles

Improves seam formation

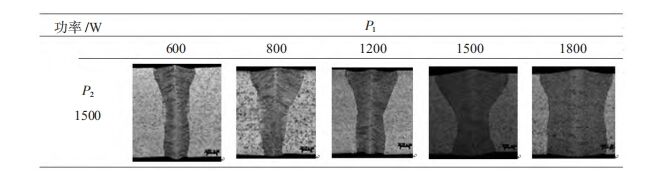

Compared to using a single laser source, the composite beam produces welds that are:

Deeper and wider

More stable with less spatter

Visually cleaner

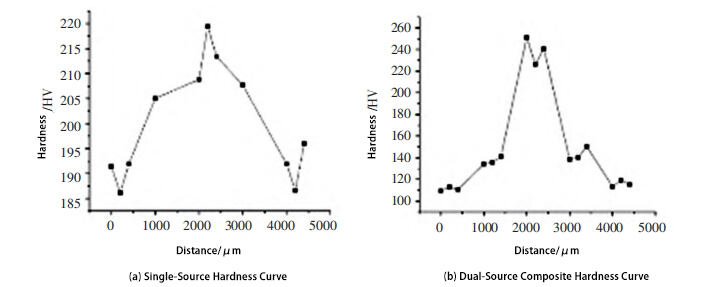

Using a Vickers microhardness tester, the study found:

Single-source weld hardness: ~208 HV

Dual-source weld hardness: ~253 HV

That’s a >20% increase in hardness, indicating stronger, more durable weld joints.

SUS304 stainless steel (0.5–1.5mm thick) is widely used in:

Kitchen cabinets

Bathroom vanities

Commercial shelving

Traditional welding may lead to:

Warping from high heat

Rough or uneven joints

Slower assembly speeds

Multi-wavelength laser welding solves these issues with:

✅ Faster operation

✅ Minimal deformation

✅ Seamless aesthetic joints

✅ Higher product reliability

Multi-wavelength composite welding represents a significant leap forward in metal fabrication, particularly for stainless steel furniture and cabinetry. By leveraging the strengths of both semiconductor and fiber lasers, manufacturers can:

Improve weld quality

Increase structural strength

Reduce post-processing

Enhance overall production efficiency