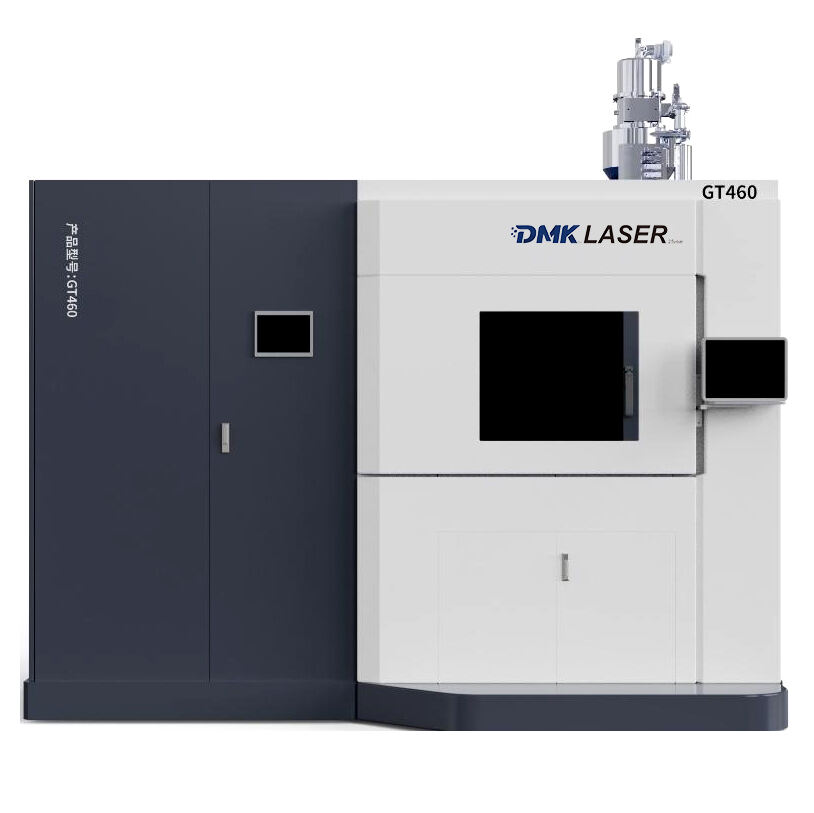

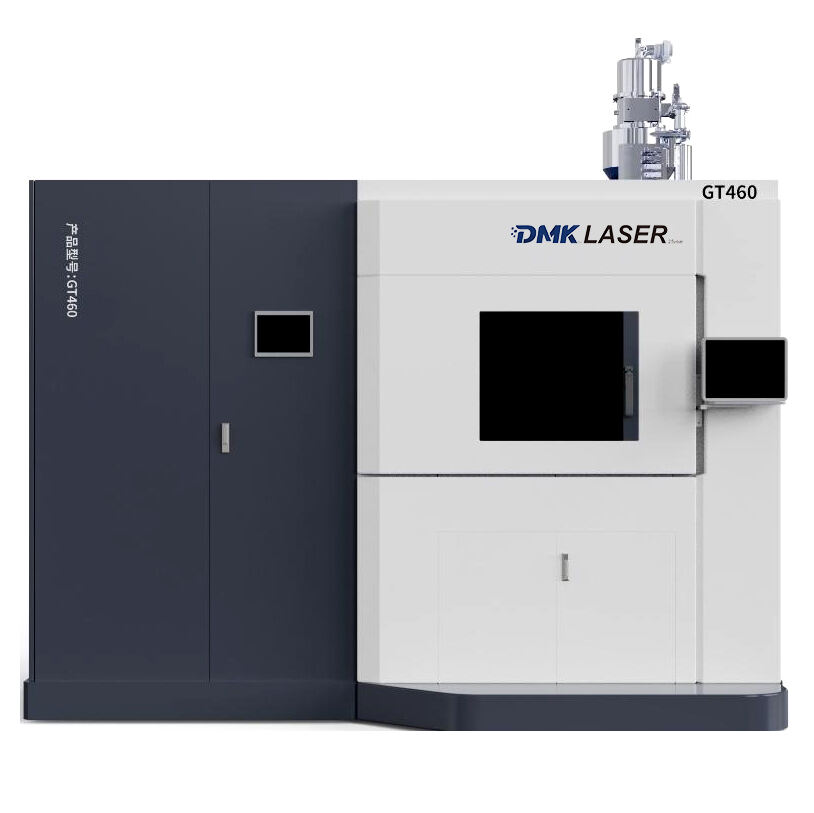

DMK GT460 Large-Format Industrial Metal 3D Printer

Description

The GT460 Large-Format Industrial Metal 3D Printer is a next-generation powder bed fusion solution designed to meet the needs of manufacturers requiring large build volumes, high-speed output, and multi-laser flexibility. It supports up to 8 high-power lasers (configurable) and offers superior powder handling with bi-directional recoating, delivering efficient and accurate part production.

Its open system supports a wide variety of high-performance metal alloys, making it ideal for industries such as aerospace, automotive, medical, energy, and tooling that demand speed, precision, and process transparency.

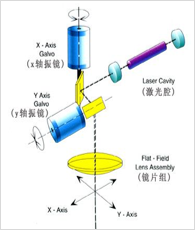

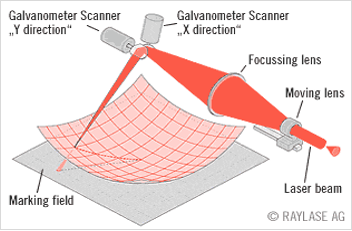

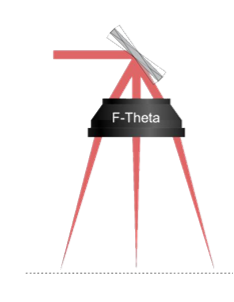

SLM optical system

field mirror

The role of the 3D-printed field mirror is to transform curvature into flatness, converting a spherical surface into a flat surface as required by the device.

|

|

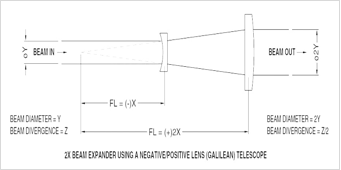

Beam expander /Scanner mirror

|

Beam expander |

Scanner mirror |

Highlights

High-Speed Multi-Laser Platform

Supports 4-laser and 6-laser setups, with 8-laser capability under development—ideal for large-volume, fast-track manufacturing.Efficient Dual-Direction Recoater

Reduces printing downtime and ensures uniform layer application across the entire platform.Operator-Centric Design

Easy-to-use control interface, streamlined maintenance access, and dual-filter safety features for enhanced usability and protection.Superior Surface Quality & Accuracy

Custom optical systems and airflow design deliver sharp detail and smooth finishes—even for dense or complex geometries.Alloy & Process Versatility

Open software platform allows the use of custom parameter sets for a wide range of materials and applications.Full Build Log Monitoring

Tracks oxygen levels, layer count, chamber pressure, powder carriage position, and more—ensuring repeatable quality for every part.

Specifications

| Parameter | Value |

|---|---|

| Machine Dimensions | 3900 mm × 1400 mm × 2850 mm |

| Build Size | 450 mm × 450 mm × 600 mm |

| Printing Accuracy | ±0.05 mm |

| Layer Thickness | 20–100 μm |

| Laser Spot Size | 75 μm |

| Laser Power | 500W × 4/6 (8-laser in development) |

| Max Scan Speed | ≤ 7 m/s |

| Build Speed | 22–55 cm³/h |

| Powder Feeding Mode | Top-Loading Powder Cylinder |

| In-Chamber Oxygen Level | ≤100 ppm |

| Shielding Gas | Nitrogen (N₂) / Argon (Ar) |

| Total Weight | 6800 kg |

| Power Requirement | 16 kW |

| Supported Software | Magics + BP, 3DXpert |

| Supported File Types | STL, OBL, STEP, etc. |

| Compatible Materials | Stainless steel, tool steel, cobalt-chrome, superalloys, titanium alloys, aluminum alloys |

Applications

Ideal For

Mass Production of Functional Metal Parts

Prototype to Production Workflows in Advanced Manufacturing

High-Precision Tooling Components and End-Use Products

Large-Volume Parts for Aerospace & Defense

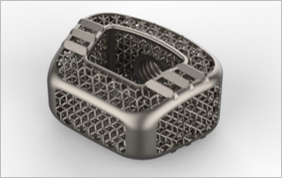

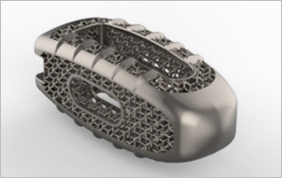

Customized Medical Implants with Biocompatibility Needs

Energy Sector Components Facing Extreme Operating Conditions

Titanium alloy porous intervertebral fusion cage | |

|

Cervical spine |

Lumbar spine |

| Aviation | |

|

Aviation bracket |

Fuel nozzle |

| Automotive Industry | |

|

Differential |

Car engine hood |

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR