Wire feed laser welding is a neat way to connect metal and it involves a special machine called a laser rust removal gun. This machine has the ability to make welding faster and more precise. Today we are going to find out about wire feed laser welding — what it is and how it work!

Wire feed laser weld is made by the laser beam, melts the metal parts into a whole. You know using some kind of insanely bright flashlight that melts two pieces of metal and makes them stick together! The machine also uses a thin wire that feeds into the laser beam to fill in the gaps between the metal pieces. This makes the weld stronger.

When to Use A Wire Feed Laser WelderThere are so many ways a Rust remover machine can be useful. One huge reason is the ability to weld extremely thin pieces of metal without warping them. So this is useful for things like electronics and jewelry where precision matters. They’re also incredibly fast workers and can help companies save time and money. And they produce less heat than other welding techniques, so the metal remains unscorched.

Wire Feed Laser Welder – Sound Difficult? It’s Not As Bad As You Think…Welding with a wire feed laser welder may seem difficult the first time you try, but it gets better with time. First, check the machine is correctly set up and the laser beam is correctly focused. You also have to feed the wire into the path of the laser beam properly and at an appropriate speed and direction in order to obtain a strong weld. It’s a good idea to practice on some scrap metal before you start with your final piece.

Numerous and people in different industries use wire feed laser welding. In the auto industry, it’s used to weld car parts together, including exhaust systems. In the airplane business, it both keeps airplane parts strong and light. And in medicine, it can pave the way for dependable medical devices. Regardless of the industry, the wire feed laser welding process always makes products better.

As with all machinery, wire feed laser welders require maintenance to perform their best. This involves the occasional cleaning, checking for and fixing anything that may be loose, and making sure all parts are in good condition. If you screw up — the laser beam doesn’t quite focus right, the wire isn’t feeding — don’t worry. Refer to the machine’s manual for assistance or consult a professional.

Our company comes with a supply that was entire, which includes eight biggest kinds of products and a variety which are huge of, like complete equipment that may become used for laser cutting, {keyword}, and laser cleaning, too equipment such as fiber lasers and laser minds. Our items are generally used in industries such as for example for example sheet metal processing and protection which is shipping that is ecological machinery which are agricultural, and the development of new power. Our goods, which could afford to export and import on their own and is growing in the share of markets which are areas that are global because East Asia, North America and Latin America, Middle East, Western Europe and Russia.

We constantly adhere to the core values of "customer-centricity" and "creating customer-satisfying value." We consider client needs as the concern that is main our selection of priorities. We earnestly take part in the "Made in China 2025 initiative" and utilize technology and services to help raise the laser markets in a means which are smart. Driven due to the dual forces regarding the Internet+ and Industry 4.0 We closely complement the needs connected with the Internet that is industrial era. We provide the essential laser that is wire feed laser welder in choice to application service when you are able to find along with get together with our partners to attain greater efficiency, speedier and faster development.

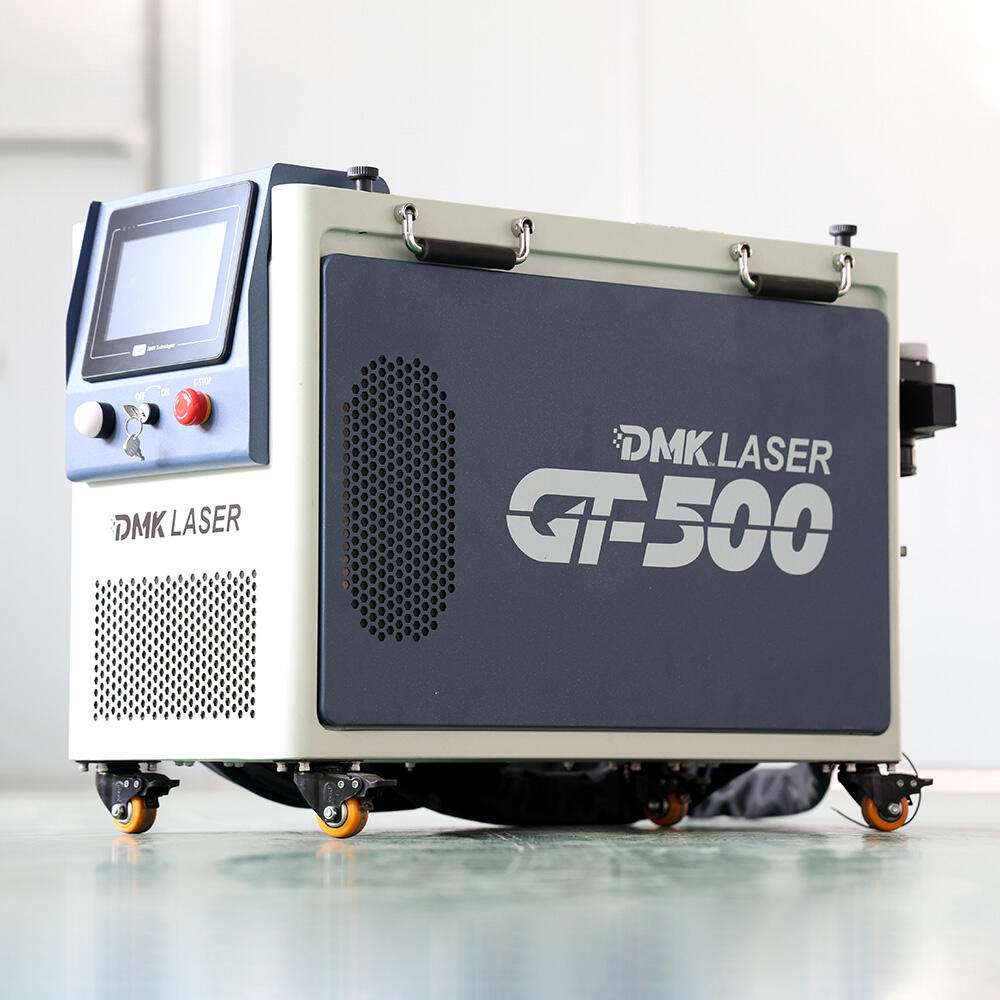

DMK is found within the East Lake High-tech Development Zone in Wuhan. We have been an enterprise which are technical in analysis, development and manufacturing of complete wire feed laser welder. We have a real quantity of scientists and postgraduates on our creator's team. We now have the state-of-the-art production facility for laser equipment and a group comprised of after-sales professionals whom can afford to offer custom solutions to customers in the international and market which is domestic. We furthermore offer expert help that was after-sales help clients solve any product-related problems promptly.

We have included the absolute most laser that is up-to-date into our processes. We work with wire feed laser welder which is domestic and control system providers like Raycus MAX, JPT Friendess Raytools SUP QILIN ESTUN. We find the elements which can be best our laser equipment, control assembly procedures, and conduct rigorous inspections regarding the factory. As a result, help us enable Chinese production to enhance the everyday lives constantly of most of our users round the world.