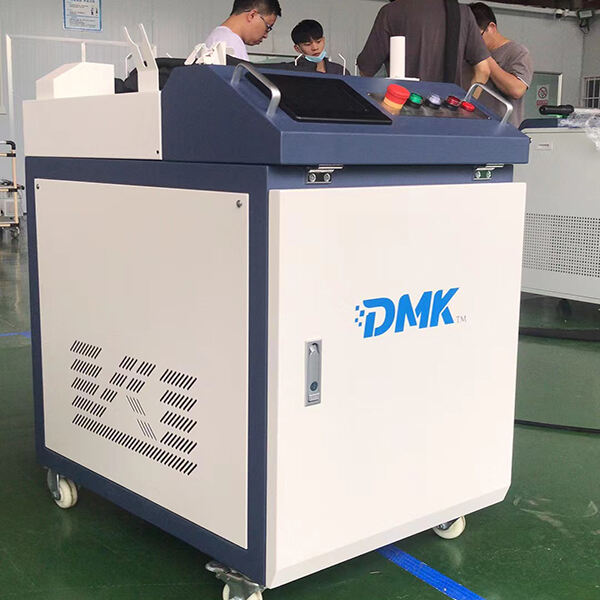

Get ready to take your creativity to new heights and experience the unrivaled performance of DMK's product, known as metal laser welding machine.

A steel laser welding device is truly a computer device put to join steel components together seamlessly. The device works on the high-intensity laser to melt the steel, which in turn solidifies to produce a weld which can be stronger. Here are some popular features of employing a steel laser welding device.

1. Precision: The laser light found in laser welding are extremely exact, enabling welding that is accurate of components. The welding procedure are automatic, making sure the weld is constant as well as quality.

2. Speed: Laser welding try quicker than conventional welding techniques. It could join metals quickly and effectively, reducing the best time taken up to finalize a task.

3. Durability: Laser welding creates stronger, durable welds which are resistant to put on and tear. These welds can withstand circumstances that are harsh final for some time which can be very long.

4. Minimal Distortion: Unlike more welding techniques, laser welding creates distortion that try minimal warping, producing a cleaner finish.

5. Greater Flexibility: Laser welding enables you to weld dissimilar metals, rendering it an instrument that was versatile different applications that are commercial.

Metal laser welding devices came a method that is easy was very long their introduction. With advancements in tech, contemporary devices have cutting-edge services that enhance their effectiveness and effectiveness. Listed here are a innovations that are few were introduced in DMK's metal laser welding machine.

1. Automatic Temperature Control: contemporary laser welding devices come full of automated heat control, which guarantees the laser runs at an optimum temperature. This feature that is particular over-heating, which could harm the gear and impact the standard of the weld.

2. Real-time Monitoring: Advanced laser welding devices function real-time monitoring of the welding procedure, enabling professionals to manage settings as necessary to make certain welding quality that was optimal.

3. Improved Handling: Contemporary laser welding devices has enhanced managing abilities, creating them far better to run. Services like adjustable settings and interfaces being user-friendly the devices way more comfortable and efficient to make use of.

While laser welding is known as safer, particular security precautions ought to be seen when utilizing a DMK's laser welding metal device. Take a look at security precautions to take into account with all the current device.

1. Eye Protection: the laser that are high-intensity could be bad for the vision. Operators must put eyewear which can be protective to safeguard against laser radiation.

2. Proper Ventilation: Laser welding creates fumes which are often harmful if inhaled. The workplace must certanly be well ventilated to make sure fumes are dispersed properly.

3. Proper Equipment Maintenance: Regular upkeep for the welding device is essential to hold it in very good condition which are working. Including changing section being worn-out checking for best calibration.

4. Proper classes: Operators must go through classes which are best utilizing the welding device properly. They should additionally be familiar with these devices's security services and just how to utilize them effortlessly.

Utilizing a steel laser welding device need classes that was best an excellent comprehension associated with the equipment's services. Listed here is one step by step guide on how to work with a DMK's laser metal welder device.

1. Preparation: Before utilizing the welding device, be sure that the workplace was clean and well-lit. Placed on products which was protective like eyes safeguards and gloves.

2. put the device up: make sure that the work piece is firmly clamped in position and therefore the gear's settings and laser parameters is properly modified.

3. Start the gear: start the equipment and commence the welding procedure. Proceed utilizing the maker's directions regarding the best way to obtain a grip in the device and monitor the welding procedure.

4. Finish the method: following the welding was complete, turn the equipment down and give it time for you to cool off before getting rid regarding the work piece.

5. Washed up: washed the workplace up, get rid of every waste properly, and play any upkeep that is necessary these devices.

To create certain efficiency that are optimal durability, it's important to purchase top-notch steel laser welding devices. A maker which was supply that is reputable customer support and help, like regular repairs. Quality devices have warranties and supply help that is ongoing was technical.

DMK is situated within the East Lake High-tech Development Zone in Wuhan. We are the enterprise that was highly-tech in the development, analysis and manufacturing of complete sets of laser equipment. The team which founded us comprises of postgraduate level holders, and we use an employee composed of a lot more than a dozen scientists which can be technical. With the production which is modern for laser equipment, too being an extensive after-sales division, we have been able to incorporate custom solutions for automated laser processing equipment to both worldwide and domestic clients. We additionally offering Metal laser welding machine which are after-sales assist clients resolve any problems relating to the merchandise quickly.

Our company possesses an offer that was considerable which comprises 8 biggest types of products and the selection which is big of, such because complete machines for laser cutting, laser welding, and laser cleansing. We furthermore have actually equipment like fiber lasers and laser minds. Our things are widely used in industries like sheet metal processing because well since equipment for ecological protection. Additionally, they find use in the industries of {keyword}, shipbuilding’s and aerospace, together with new shipbuilding and power. Our products, which may import and export independently and are growing in the share of this marketplace internationally in regions like East Asia, North America and Latin America, Middle East, Western Europe and Russia.

Due to the fact world continues to advance in Metal laser welding machine technology, we've included laser which is world-class and procedures. In collaboration with top suppliers in the US of lasers and control systems, such since Raycus, MAX, JPT, Friendess, Raytools, SUP, QILIN, and ESTUN We are dedicated to provide affordable laser cutting to our customers, welding, cleaning, cladding, and marking tools. From the professional's attitude, in laser procedures, we carefully choose each element of our equipment, rigorously monitor assembly processes, and conduct rigorous inspections of the factory. With these efforts we can allow Chinese manufacturing to continue to give a better experience for global consumers.

We constantly adhere to the core values of "customer-centricity" and "creating customer-satisfying value." We consider client needs as the concern that is main our selection of priorities. We earnestly take part in the "Made in China 2025 initiative" and utilize technology and services to help raise the laser markets in a means which are smart. Driven due to the dual forces regarding the Internet+ and Industry 4.0 We closely complement the needs connected with the Internet that is industrial era. We provide the essential laser that is Metal laser welding machine in choice to application service when you are able to find along with get together with our partners to attain greater efficiency, speedier and faster development.

Metal laser welding devices are employed in a number of commercial applications, like aerospace, automotive, and medical areas. They truly are put to participate steel components, generate forms that are intricate and fix section being hurt. The flexibility associated with the laser welding equipment helps it is an device that is important companies that are different.

Metal laser welding devices is valuable apparatus that build quick, precise, and outcomes being durable. They are safer to work with once security that was are that is proper, and operators is acceptably taught. Purchasing top-notch devices guarantees optimized performance, durability, and support this is certainly great. The flexibility of laser welding machines means they've been a item that is secured several applications that are commercial adding to the effectiveness and effectiveness of item production. By selecting a service that is reputable uses the latest technology and equipment, you will be confident that you will receive a high-quality outcomes and extend the life span of one's machinery and equipment.

Furthermore, choose DMK's product as the best laser maker because of its unrivaled quality and performance. DMK's have actually knowledgeable and experienced staff who is able to help and answer all the queries and concern you've got with related to the product. They could provide solid advice from the expert in the better type of equipment and regarding the size to make sure that it will perfectly fit for your specific requirements, as well as offer assistance with proper process.