OK, so welding from this angle with an Industrial laser cleaning machine is pretty cool, and pretty special. Ever wonder how cars, airplanes, and even your favorite toys are built just right? A key, of course, to making such things is to use an industrial laser welder. Now, let’s take a closer look at how these incredible machines operate and what they can do!

First, let’s clarify what we mean by precision welding. Precision welding is when you weld two metal pieces together with a lot of care and finesse. It’s like a puzzle, except that all the pieces need to fit perfectly. An industrial laser welder is a machine that does this precision welding by using a special type of light called a laser. It’s as if you are using an extra-powerful flashlight and shining it on a piece of metal to melt it and stick it back together in precisely the right place.

Technologically advanced laser welding: The more we can do with laser welding, the quicker and better we can make things. These machines allow companies to produce goods rapidly and with high precision. By doing so much more quickly than anyone could by hand, industrial laser welders save a lot of time. This allows companies to produce more stuff, more quickly — great if you have to keep pace with the high demand for various types of things.

Now, what are the applications of industrial laser welders. These amazing contraptions can be used in all kinds of places, to make cars and airplanes to electronic devices and medical equipment. They can even weld extremely small components that are too small for human hands to handle. In factories, industrial laser welders are a type of superhero that companies use to make all sorts of stuff quickly and precisely.

Yet another advantage which comes with utilizing an industrial laser kick the bucket welder is smooth welding. When two metal parts are welded together, the join is sometimes almost invisible. This allows the end product to resemble something made from a single piece of metal, with no seam or rough edge to be found. It's amazing! Seamless welds are some of the most perfect welds you can produce and sometimes you can’t even tell where one piece ends and the other begins. Industry laser welders can bring this to your enterprise.

Finally, strong welds are important for making certain products are durable and will have a long-lasting life. When metal is welded by a laser, the connection is extremely strong. This translates to end products produced using the industrial laser welders will have a lower risk of breaking or falling apart, even under severe conditions. This solid weld quality means whatever you’re making will last and work well for years to come.

We have integrated the laser technology that is latest into our processes. In collaboration with top suppliers in the US of lasers and control systems such since Raycus, MAX, JPT, Friendess, Raytools, SUP, QILIN, and ESTUN We are committed to supply the market with low-cost laser cutting, welding, cleaning, cladding, and marking equipment. We choose very carefully the elements which get into our laser equipment, manage assembly procedures, and conduct factory which is rigorous. Using this method, we permit industrial laser welder to supply a best constantly enjoy for each of our customers across the world.

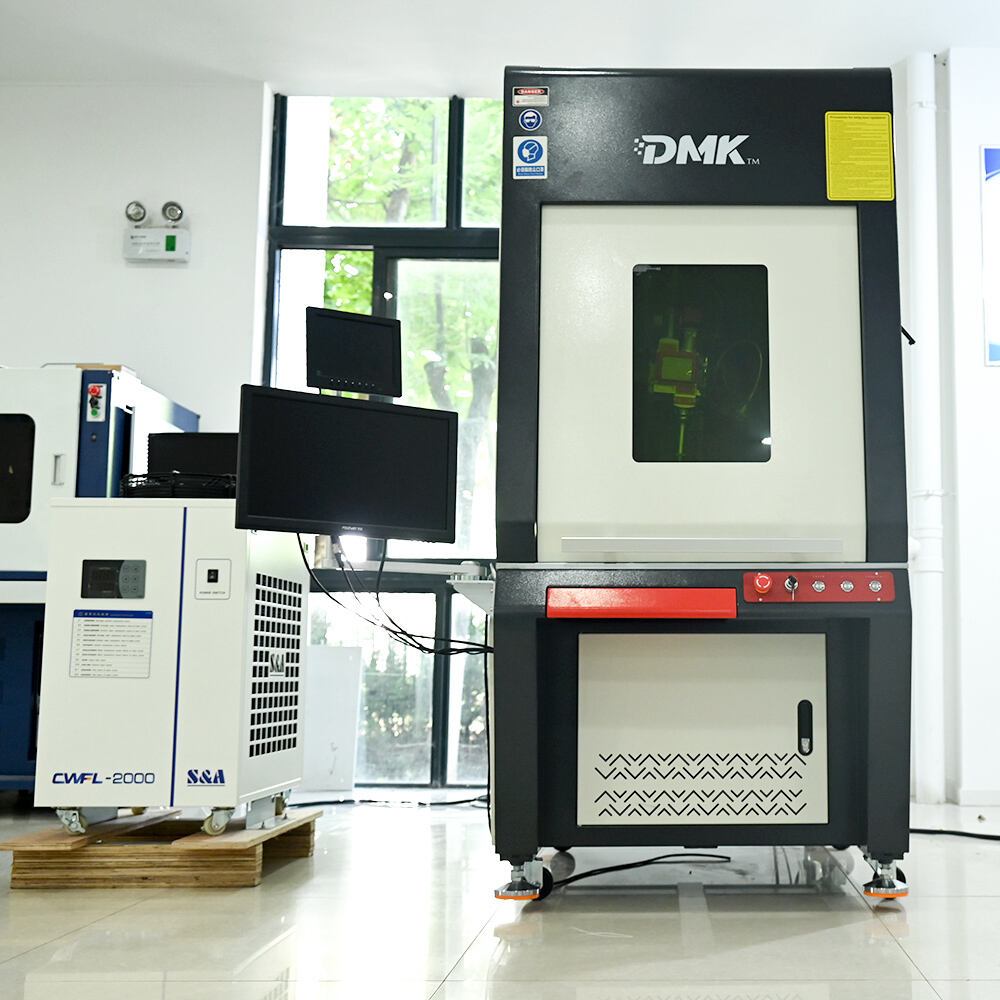

DMK is situated inside the East Lake High-tech Development Zone (Optics Valley) in Wuhan, China. Our company is the company which try high-tech specializes in developing, research, manufacturing and distribution of complete laser equipment. The creator's group was comprised of postgraduate degree holders and we now have an organization comprised of greater than a dozen researchers which can be technical. With the manufacturing center that is current for laser equipment, in addition to a comprehensive after-sales team that may provide custom solutions for laser processing equipment that try automated to worldwide and domestic customers. We also offer professional after-sales support to help users resolve any pressing dilemmas with their products or industrial laser welder.

Presently, our company has generated a supply chain which covers eight biggest areas and lots of products that add complete machine production of laser machines that is cutting laser machines which is welding cleansing machines and the supply of elements fiber which are including cutting minds for lasers, laser welding minds since laser cleaning head and laser control systems. Our products are commonly used in industries such as for instance for example sheet metal processing and protection that are {keyword} which is agricultural shipbuilding, aerospace, and energy that will be additionally new. The Middle East, Western Europe, and Russia with the capability to export and import goods minus restriction our merchandise have won more market share in international areas like East Asia, North America, Latin America.

We always adhere to the core values of "customer-centricity" and "creating customer-satisfying benefits." We place customer needs near the most notable of our concern list. We actively take part in the "Made in China 2025" initiative" utilizing technologies and services to enhance the effectiveness associated with the laser business. Inspiring by the two forces for the Internet+ and Industry 4.0 We closely complement the market needs that are the result which is direct industrial online years. You can expect the important industrial laser welder and application services in industry, and get together with our lovers to achieve greater quality, faster and more growth which was cost-effective.