I. Problem Identification: The Conflict Between Wear-Corrosion Resistance Needs and Traditional Technologies In fields such as aerospace and petrochemical engineering, corrosion and wear account for 80% of total component failures, leading to equipme...

Contact Us

In fields such as aerospace and petrochemical engineering, corrosion and wear account for 80% of total component failures, leading to equipment downtime and increased costs. Traditional protective technologies have obvious limitations: hard chrome plating pollutes the environment; thermal spraying coatings have poor bonding strength; physical vapor deposition is inefficient; and traditional laser cladding easily causes component deformation. Therefore, the green and efficient preparation of high wear-corrosion resistant protective coatings has become an urgent problem to be solved in the industry.

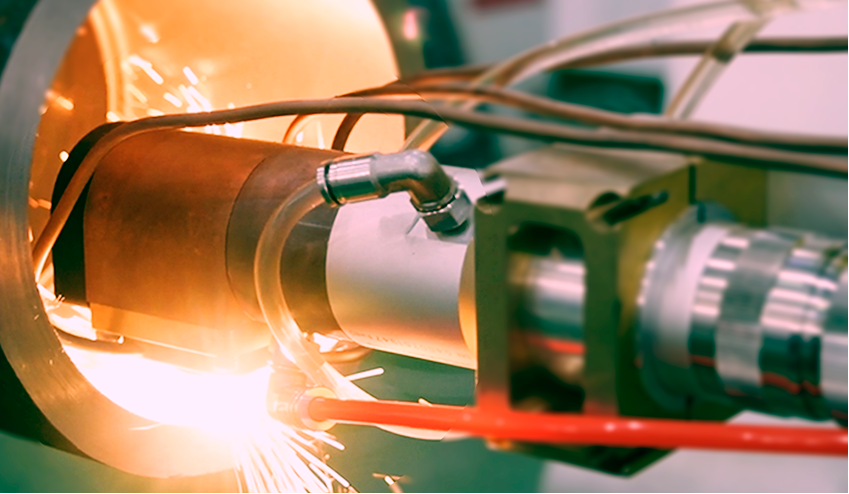

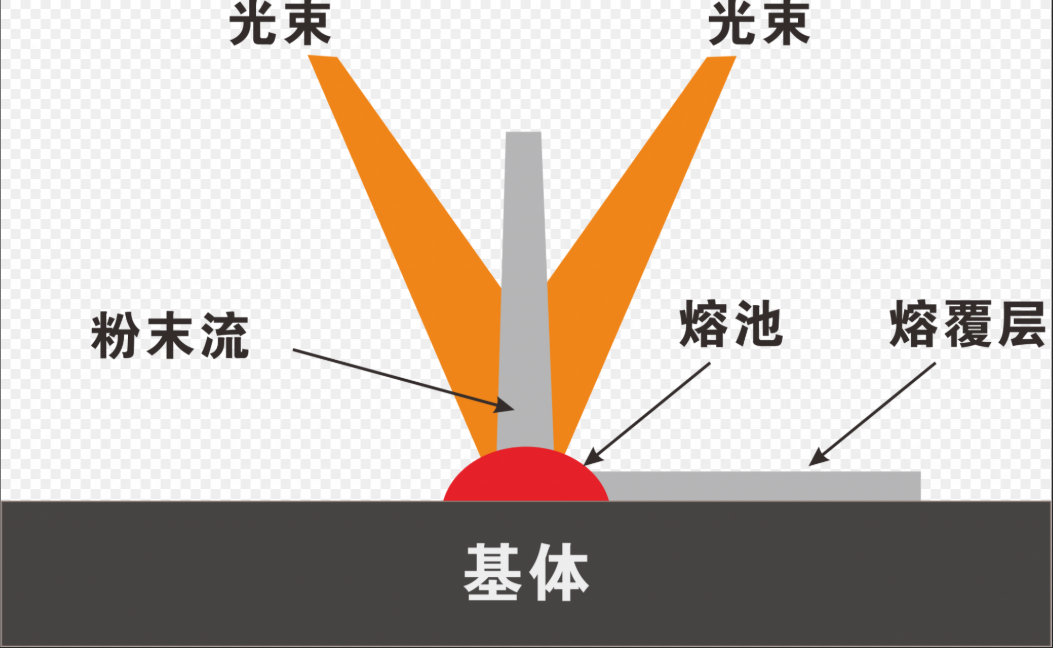

Ultra-High-Speed Laser Cladding Technology (EHLA) is optimized from traditional laser cladding,

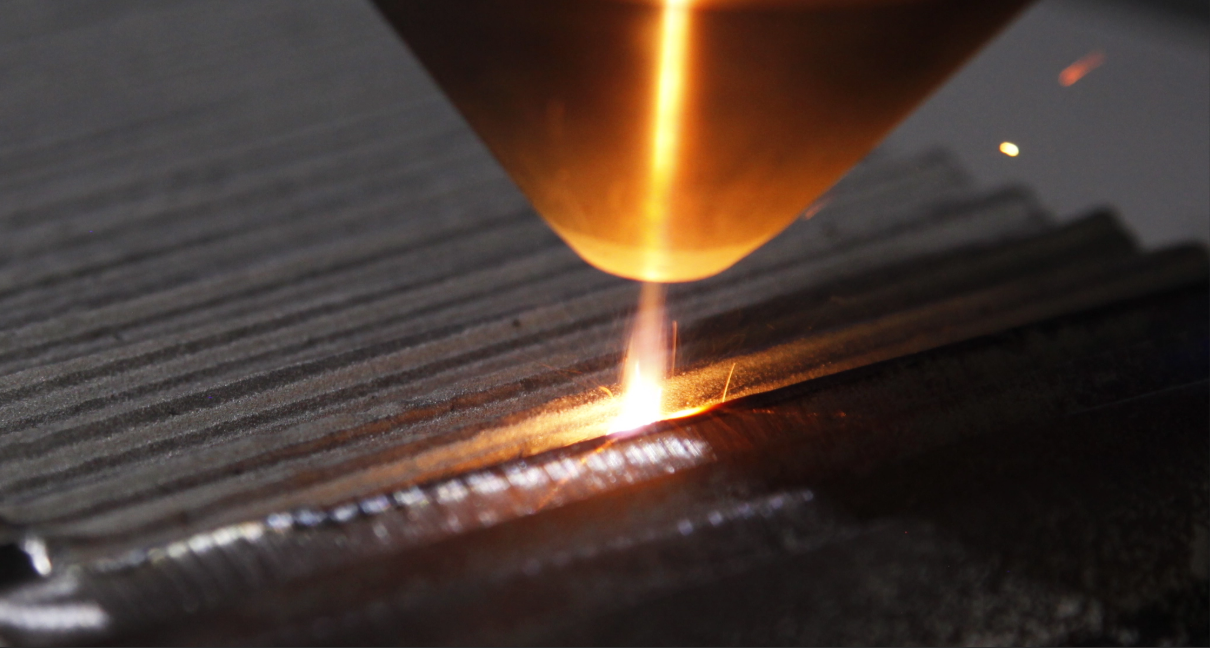

achieving efficient energy distribution by regulating the interaction position of laser, powder and substrate. The focal point of its laser and powder beam is above the substrate, so the powder melts before reaching the substrate. Combined with coaxial powder feeding, the cladding linear speed reaches 500 m/min, which is 10 times more efficient than traditional technology.

In terms of energy distribution, 80% of the laser energy is used to melt the powder, and only 20% to heat the substrate, bringing three advantages: the coating dilution rate is less than 4%; low heat input to the substrate prevents deformation; the cooling rate of 1.08×10⁵ K/s refines grains (the dendrite size of iron-based coatings is only 0.9 μm). In addition, the coating roughness (Ra) is less than 10 μm with low defect rate. In terms of equipment, Germany’s ACunity and TRUMPF, as well as China’s Xi’an Zhongke Zhongmei and Xi’an Jiaotong University, have made breakthroughs, laying the foundation for industrialization.

EHLA’s application relies on adaptive coatings, divided into traditional alloys and new materials:

Among traditional alloy coatings, iron-based alloys match steel substrates and are used in mining and petroleum equipment (e.g., Shandong Energy’s hydraulic prop coatings); cobalt-based alloys are high-temperature resistant, applied in casting rolls and turbine blades; nickel-based alloys resist high-temperature corrosion, suitable for biomass boiler pipes.

New material coatings expand application boundaries: iron-based amorphous coatings (96% amorphous content) are used in precision machinery; high-entropy alloy coatings (e.g., FeCoNiCrMn) with no cracks apply to aero-engines; composite coatings (e.g., WC-reinforced) with toughness and hardness are used in mining machinery; ZrB₂-SiC ceramic coatings fit high-temperature bearings.

EHLA needs to overcome two bottlenecks: first, build a standardization system, develop special coating materials, and establish process databases and quality standards; second, integrate auxiliary technologies, introduce ultrasonic/electromagnetic fields to regulate molten pools, promote post-processing technologies, and develop AI visual monitoring systems to improve automation.

With the decline in equipment costs, EHLA is expected to penetrate small and medium-sized enterprises, replace traditional processes, become a mainstream surface engineering technology, provide green and efficient solutions for industrial component protection, and boost the high-quality development of the manufacturing industry.