For craftsmen, manufacturers, and business owners, choosing the right glass laser marking machine is key to unlocking the value of glass processing. A suitable device can transform ordinary glass into high-quality products with personalized designs or professional brand logos. However, the wrong choice may lead to poor results, material damage, or wasted investment. There is no absolutely "best" glass marking machine— the core is to find a model that fits your specific needs. This guide breaks down the core dimensions of selection, details the characteristics of different laser technologies, and helps you quickly lock in the optimal solution. Among them, dual-laser all-in-one machines, as multi-functional integrated solutions, are particularly suitable for beginners and scenarios with diverse needs.

I. Clarify Core Requirements: The First Step is "Knowing Yourself"

Before comparing equipment, it is necessary to sort out the core demands of the project and accurately position the needs from three dimensions: effect, material, and production capacity.

1. Define Expected Effects: Match Processing Methods as Needed

Different visual effects correspond to different laser technologies, which need to be planned in advance:

- Deep frosted/etched effect: For deep, delicate-to-touch frosted engravings, carbon dioxide (CO₂) lasers are the industry standard choice;

- Fine details/micro-markings: To create complex graphics, serial numbers, or intricate designs on crystal or coated glass, the "cold processing" precision of ultraviolet (UV) lasers is more suitable;

- High-contrast black markings: To leave permanent black marks, laser marking sprays (such as Cermark, Thermark) are required, which can be used with either CO₂ lasers or fiber lasers.

2. Adapt to Glass Materials: Different Materials Corresponding to Different Technologies

Differences in glass materials directly affect equipment compatibility, avoiding damage caused by material mismatch:

- Ordinary glass (soda-lime/borosilicate glass): It has good compatibility with CO₂ lasers, with stable processing effects and high cost-effectiveness;

- Special glass (crystal, coated, tempered, colored glass): The material is fragile or has a special surface, so mild and high-precision UV lasers must be used to prevent cracking, burning, and other issues.

3. Match Production and Business Needs

Make decisions based on budget, production capacity, and multi-functional needs:

- Budget considerations: CO₂ laser equipment usually has a lower initial purchase cost than UV laser systems, making it suitable for entry-level scenarios with limited budgets;

- Speed and output: For mass production, priority should be given to CO₂ lasers with faster processing speeds; although UV lasers have high precision, they are less efficient when processing complex workpieces, making them more suitable for small-batch fine processing;

- Multi-functional needs: If you plan to process multiple materials such as wood, acrylic, metal, and plastic at the same time, you need to choose equipment with multi-material compatibility to avoid repeated investment.

II. Analyze Laser Technology Types: Choosing the Right "Core Power" is Key

The laser light source is the core of the marking machine. Different technical types have significant differences in applicable scenarios, and accurate selection must be made according to needs:

1. CO₂ Laser Marking Machine: The "Cost-Effective Choice" for Ordinary Glass Processing

As a general-purpose mainstay for glass engraving, CO₂ lasers generate light with a wavelength of 10.6μm through gas tubes, which can be efficiently absorbed by glass, easily achieving deep frosted etching effects. It is suitable for engraving text, logos, and decorative patterns on ordinary glass, featuring cost-effectiveness and mature technology. However, in processing sensitive materials or ultra-fine details, the precision is slightly inferior to that of UV lasers.

2. UV Laser Marking Machine: The "Precision Master" for Fine Processing

Using short-wavelength UV light of 355 nanometers, it interacts with materials in a "cold processing" way, removing materials at the micro level with almost no thermal stress. It is particularly suitable for processing fragile glass, crystal products, and complex patterns, and can create smooth and delicate frosted surfaces, making it the first choice for precision micro-markings. The disadvantage is the high initial purchase cost and relatively slow processing speed.

3. Fiber Laser Marking Machine: A "Specialized Tool" for Special Coated Glass

Designed primarily for metal and plastic processing, lasers with a wavelength of 1.06μm usually penetrate bare glass directly and cannot achieve direct marking. It is only applicable to glass with special marking coatings and needs to be used with dedicated coatings, so its applicability in pure glass processing scenarios is limited.

4. Dual-Laser All-in-One Machine: An "Integrated Solution" for Multi-Functional Needs

Integrating CO₂ laser and UV laser into one machine, it achieves "one machine for multiple uses": CO₂ laser is responsible for deep etching and frosted effects on glass, UV laser handles fine patterns and special glass, and it is also compatible with multiple materials such as wood, metal, and plastic. With a compact and portable design and user-friendly software, its cost and occupied space are much lower than the sum of two dedicated devices, making it particularly suitable for start-ups, small workshops, or projects with diverse needs.

III. Evaluate Equipment Performance and Configuration: Details Determine User Experience

In addition to the core laser technology, the performance parameters and configuration of the equipment also affect the processing effect and stability. The following dimensions need to be focused on:

1. Marking Area and Precision

The size of the workbench must be able to accommodate the largest processed workpiece to avoid limiting production due to size constraints; resolution (in DPI) directly determines the clarity of details, and high-resolution equipment is required for fine processing scenarios.

2. Software and Usability

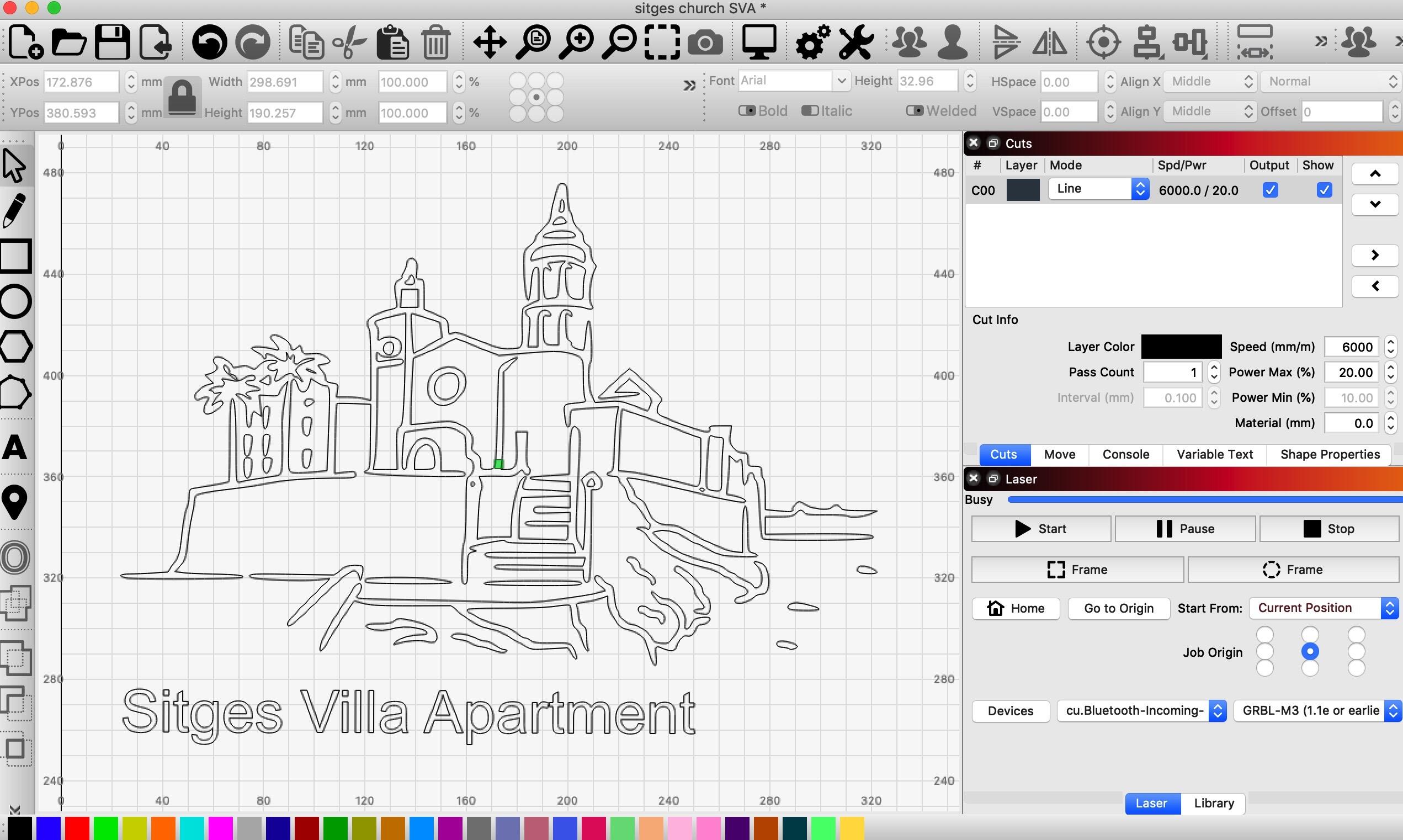

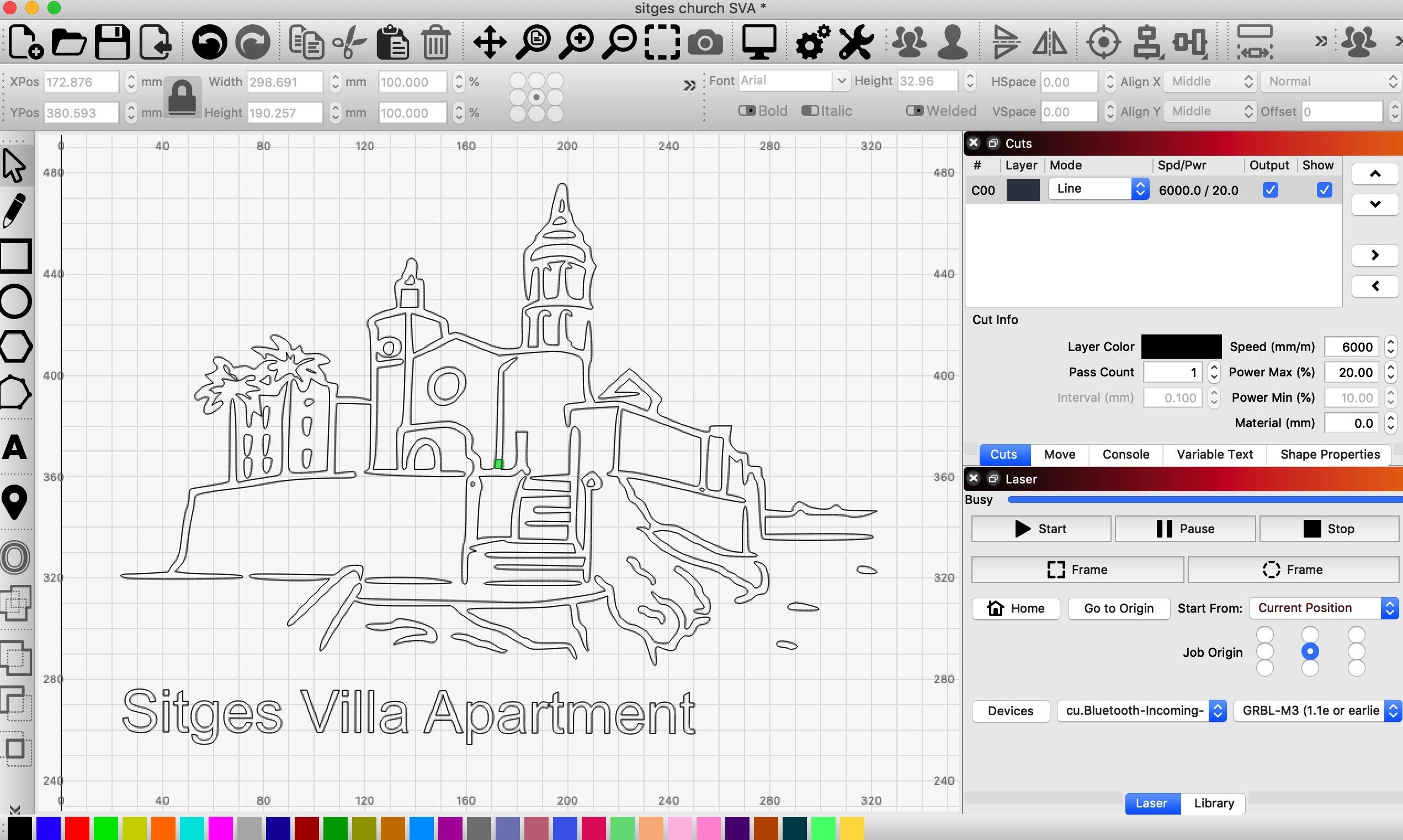

User-friendly software (such as LightBurn, EzCad2 compatible software) can simplify the processes of design import and parameter debugging, lowering the operation threshold, especially suitable for beginners.

3. Cooling System

The cooling method (air cooling or water cooling) affects the stability and service life of the equipment during long-term operation. For high-frequency and long-time processing, a water cooling system with better heat dissipation effect should be selected; for small-batch processing, a portable air-cooled equipment can be chosen.

4. Safety and Compliance

The equipment must be equipped with safety functions such as a closed workspace, protective observation window, and emergency stop button, and comply with relevant international safety certification standards to ensure the safety of operators.

IV. Quick Selection Path: Match the Right Equipment According to Needs

According to core needs and business scenarios, the suitable equipment type can be quickly locked:

1. Need: Processing Multiple Materials (Glass + Wood/Metal/Plastic, etc.)

- Application scenario: Small workshops, e-commerce sellers who need to customize multi-material products;

- Recommended type: Dual-laser all-in-one machine;

- Core advantages: Integrates two laser technologies, compatible with multi-material processing, saves space and cost, and meets the needs of diverse projects.

2. Need: Glass Surface Decoration, Small-Batch Production

- Application scenario: Hobbyists, entrepreneurs, small craft stores with limited budget and space;

- Recommended type: Portable entry-level CO₂ laser marking machine;

- Core advantages: High cost-effectiveness, compact size, can achieve glass frosted effects and basic pattern engraving, suitable for entry-level and light-duty applications.

3. Need: Professional-Grade Glass Customization and Processing

- Application scenario: Professional customization workshops focusing on mid-to-high-end projects (trophies, gifts, art glass), emphasizing quality and details;

- Recommended type: High-end desktop CO₂ laser marking machine;

- Core advantages: Large working area, high precision, stable performance, can handle complex designs, and ensure professional-level processing effects.

4. Need: Non-Destructive Marking of Precision Components (Electronic, Medical, etc.)

- Application scenario: Processing ultra-thin and fragile glass (mobile phone covers, optical lenses, medical devices) requiring micron-level precision;

- Recommended type: High-precision UV laser marking machine;

- Core advantages: "Cold processing" reduces thermal impact, achieves stress-free and crack-free fine marking, meeting the requirements of the precision industry.

5. Need: High-Speed Marking for Automated Production Lines

- Application scenario: Large manufacturers needing mass marking (batch numbers, dates) on glass containers in beverage, pharmaceutical, and cosmetic filling lines;

- Recommended type: Industrial-grade high-speed laser marking machine;

- Core advantages: High protection level, fast marking speed, strong reliability, suitable for 24/7 continuous operation, and can be integrated into automated production lines.

Conclusion

The core of selecting a glass laser marking machine is "adaptation" rather than "pursuing high prices": dual-laser all-in-one machines excel in multi-functional integration, UV lasers win in precision and non-destructiveness, and CO₂ lasers are superior in cost-effectiveness and efficiency. Your specific needs, material types, and production capacity together determine the final optimal solution. Before selection, it is recommended to request sample testing of actual materials to intuitively verify the equipment's processing effect. If you need to further understand equipment parameter comparisons or obtain customized selection suggestions,

you can contact a professional team immediately to start an efficient and precise glass processing journey.