In fields such as industrial production, cultural relic protection, and equipment remanufacturing, contaminants like rust, oxide scales, and oil stains on metal surfaces directly affect product quality and service life. Traditional cleaning methods such as mechanical grinding and chemical cleaning suffer from low efficiency, environmental pollution, and easy substrate damage. Laser cleaning technology for metal surfaces, with its advantages of non-contact processing, environmental friendliness, high efficiency, and precision, has become a popular application direction in the laser industry. It achieves rapid stripping of contaminants through physical and chemical interactions between laser energy and pollutants, without damaging the metal substrate while meeting high cleanliness requirements, providing a new solution for metal surface treatment.

Laser Cleaning Principle: Energy-Driven "Contaminant Stripping Technology"

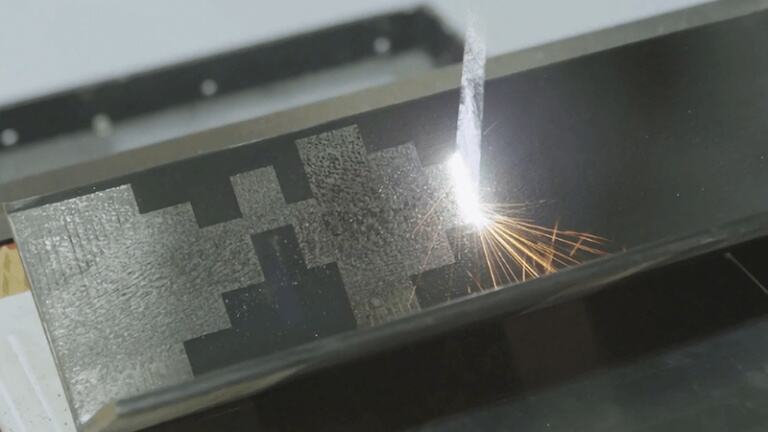

The core principle of laser cleaning for metal surfaces is to utilize the high-energy characteristics of lasers to break the bonding force between contaminants and the metal surface through physical and chemical effects such as thermal effects and shock wave effects, enabling contaminants to detach from the substrate. When laser irradiates the metal surface, contaminants absorb laser energy, instantly reach the melting or vaporization temperature, and detach after expansion, combustion, and decomposition; the high-intensity shock wave generated by pulsed lasers causes high-frequency vibration of contaminants, further accelerating their stripping. Due to the high reflectivity of metal substrates to lasers, there is no damage after cleaning, achieving "non-destructive cleaning".

Laser cleaning is mainly divided into dry cleaning and wet cleaning. Dry cleaning directly acts on contaminants through laser radiation, featuring simple operation and no secondary pollution, suitable for cleaning most metal surfaces; wet cleaning applies liquid medium to the metal surface before laser irradiation, which can improve cleaning efficiency, suitable for metals with severe pollution or special materials. In addition, under special working conditions, inert gases or special chemical reagents can be combined to further optimize cleaning effects and expand application scope.

Core Advantages: Why Replace Traditional Cleaning Technologies?

Compared with traditional cleaning methods, laser cleaning of metal surfaces has significant advantages. Firstly, it is environmentally friendly. The entire process requires no chemical reagents or abrasive materials, produces no wastewater or waste residue, and achieves cleaning only through the reaction between laser and contaminants, complying with the environmental requirements of modern industry. Secondly, it is non-destructive and efficient. Laser is a non-contact processing method that does not cause mechanical damage to the metal substrate. With fast cleaning speed, it can quickly remove micron-level and submicron-level contaminants, with efficiency far exceeding manual grinding and chemical cleaning. Thirdly, it is precise and controllable. By adjusting parameters such as laser power and pulse frequency, it can adapt to different metal materials and contaminant types, achieving precise cleaning from fine stains on precision components to thick rust layers on large equipment.

In practical applications, these advantages are particularly prominent. For example, the titanium nitride film on the surface of engine turbine blades is difficult to strip by traditional methods and is easy to damage the blades, while a 10W fiber laser can clean it efficiently; the dirt in the small holes of filters in the chemical and pharmaceutical industries has high traditional cleaning costs and poor effects, while laser pulse cleaning can complete the cleaning at low cost and without damage. In addition, laser cleaning can realize automatic operation, adapting to the high-efficiency operation needs of industrial production lines and reducing labor costs.

Application Scenarios: Multi-Field Coverage from Industrial Production to Cultural Relic Protection

The application scenarios of laser cleaning for metal surfaces are constantly expanding, having penetrated into multiple fields such as industrial production, cultural relic protection, and equipment remanufacturing. In industrial production, it can be used for derusting, degreasing, and oxide scale removal of metal components, laying a good foundation for subsequent processing such as welding and coating; in the field of equipment remanufacturing, it can renovate the surface of waste metal equipment, restore its performance, and realize resource recycling; in the field of cultural relic protection, aiming at the rust and dirt of metal cultural relics, the non-contact characteristic of laser cleaning can avoid damage to the cultural relic structure, achieving "non-destructive cleaning and restoration".

In addition, laser cleaning is also suitable for special scenarios such as precision cleaning of metal products in the microelectronics industry and surface decontamination of nuclear power equipment. For example, in the protection of metal cultural relics, lasers can accurately remove surface rust without moving the cultural relics, retaining the original structure of the cultural relics; in filter cleaning, it can efficiently clean contaminants in small holes without damaging the filter material, greatly reducing cleaning costs.

Technological Upgrades: Innovative Solutions to Address Pain Points

To further improve cleaning effects and expand application scope, laser cleaning technology for metal surfaces is constantly being upgraded and optimized. Aiming at the secondary pollution caused by the diffusion of contaminant particles during cleaning, a transparent film can be covered on the metal surface to make the detached contaminants adhere to the film, realizing the isolation between the clean area and the contaminated area, especially suitable for the cleaning of special scenarios such as nuclear power equipment.

At the same time, optimizing the laser incidence method can also improve cleaning efficiency. Changing the traditional vertical incidence to inclined incidence allows the thermoelastic stress formed by laser radiation to directly act on the contact surface between contaminants and metals, accelerating contaminant stripping, and the radiation area is about 10 times larger than that of vertical incidence, further improving cleaning speed. In addition, by accurately adjusting parameters such as laser power density and pulse width, the impact of thermal effects on the metal substrate can be avoided. For example, when cleaning steel plate rust, controlling the laser pulse power density at 180MW/m² can replace the thermal stress effect with the gasification effect, achieving non-destructive cleaning.