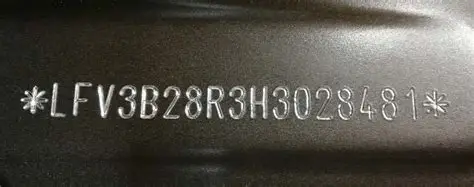

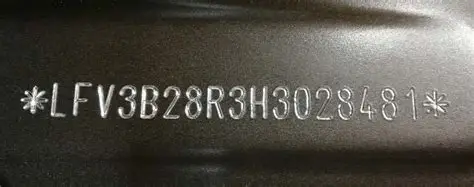

In automotive manufacturing, the VIN (Vehicle Identification Number) serves as the vehicle's "ID card," carrying key functions such as vehicle traceability, quality control, and anti-counterfeiting. According to national standards, the VIN must be engraved on key structural components of the white body, meeting requirements of a character height of no less than 7mm, a depth of no less than 0.3mm, clarity, durability, and non-replaceability. Traditional mechanical marking processes suffer from low efficiency, high noise, and limited adaptability.

Laser marking, with its advantages of non-contact processing, high precision, and high stability, has become the mainstream technology for VIN engraving on automotive white bodies, providing core support for efficient production and precise traceability in the automotive industry.

Laser Marking: The "Non-Contact Engraver" for Automotive VIN Codes

Laser marking is a technology that uses high-energy laser beams to locally irradiate metal surfaces, evaporating surface materials to expose underlying layers or triggering chemical color changes to form permanent marks. Unlike mechanical marking methods such as pneumatic scribing, dot-matrix, and embossing, laser marking is a non-contact process that requires no direct contact between the marking needle and the body sheet metal. This avoids structural damage to the vehicle body caused by mechanical forces and can adapt to various body component materials—whether ordinary carbon steel or hot-formed steel with a yield strength exceeding 1300MPa, laser marking can stably achieve the required depth and clear characters.

In automotive white body production lines, laser marking equipment typically consists of a laser generator, beam expander (configured as needed), and galvanometer system. Combined with automated control systems, it can quickly adapt to production needs of multiple vehicle models and marking positions. The marking process produces no mechanical noise, completing engraving only through high-speed laser beam scanning. It not only meets the high-efficiency requirements of welding production lines but also ensures the consistency and aesthetics of VIN codes, solving the pain point of traditional mechanical marking struggling to balance speed and quality.

Core Technical Differences: Choosing Between Front-Focus and Rear-Focus Galvanometers

The effectiveness of laser marking for VIN engraving depends critically on the focusing method of the galvanometer system, mainly divided into front-focus and rear-focus galvanometer types, each with distinct advantages and suitable for different production scenarios.

Front-focus galvanometer systems use a long-focal-length dynamic focusing device to focus the laser beam before it enters the XY galvanometers. This ensures a consistent distance from every point on the workpiece plane to the focusing lens, with all focused light spots accurately landing on the same plane. The marking effect is optimal, with clear characters and uniform depth, fully meeting the strict standards for VIN codes. In contrast, rear-focus galvanometer systems focus the laser beam through a lens after it is scanned by the galvanometers. This method features simple control software, low cost, and fast marking speed, but due to the fixed distance between the lens and the workpiece, the spot size varies across the scanning plane—smaller in the center and larger around the edges—potentially causing pincushion or barrel distortion. It is suitable for scenarios with slightly lower marking precision requirements. In automotive white body production, front-focus galvanometer systems are preferred by mainstream automakers for their precision advantages.

Process Advantages: Why It’s the First Choice for the Automotive Industry

Laser marking stands out in automotive VIN engraving due to multiple advantages adapting to industrial production. Firstly, it offers wide adaptability, handling both ordinary carbon steel and high-hardness hot-formed steel—while mechanical marking often struggles with insufficient engraving depth and needle wear when processing high-strength steel. Secondly, it balances efficiency and quality: by optimizing laser power (commonly 150-200W) and marking parameters, a 19-digit VIN can be engraved in 30-60 seconds. For improved aesthetic quality, multi-pass high-speed scanning can further enhance character clarity and avoid slag residue. Thirdly, it delivers strong stability: laser marking has no mechanically worn parts, resulting in low maintenance costs and suitability for long-term continuous operation on automotive production lines. Meanwhile, non-contact processing reduces the risk of secondary damage, ensuring the integrity of the vehicle body structure.

Additionally, laser marking offers exceptional flexibility. Through software programming, it can quickly switch VIN marking schemes for different vehicle models without changing molds or fixtures, significantly reducing production line changeover time and perfectly matching the mixed-model production needs of modern automotive manufacturing.

Application Considerations: Balancing Safety and Efficiency

Despite its significant advantages, laser marking in automotive white body applications requires attention to two core points. Firstly, safety protection: during marking, the ablation of oil films on body sheet metal and metal evaporation generate smoke and dust, while intense laser radiation may harm operators' eyesight. Therefore, complete ventilation and exhaust systems and light radiation protection equipment must be installed to ensure a safe production environment. Secondly, parameter optimization: there is a certain inverse relationship between laser marking efficiency and quality—reducing laser beam speed and marking passes improves efficiency but may leave slag on character edges; multi-pass high-speed scanning ensures aesthetics but takes longer (approximately 4-6 minutes). In practical production, a balance must be struck based on production line rhythm.

As the automotive industry continues to raise requirements for production efficiency and traceability precision, laser marking technology is evolving toward faster speeds, higher precision, and smarter adaptability. It not only serves as the core technology for VIN engraving but also plays a crucial role in marking and traceability of automotive components and electronic parts, driving the intelligent upgrading of the manufacturing industry.