레이저 절단은 오랫동안 자동차 부품에서 항공 우주 부품에 이르기까지 산업 생산의 필수 요소로써 재료 처리가 정확하고 효율적으로 이루어졌습니다. 다양한 레이저 절단 기술 중, 섬유 레이저 절단 ra...

문의하기

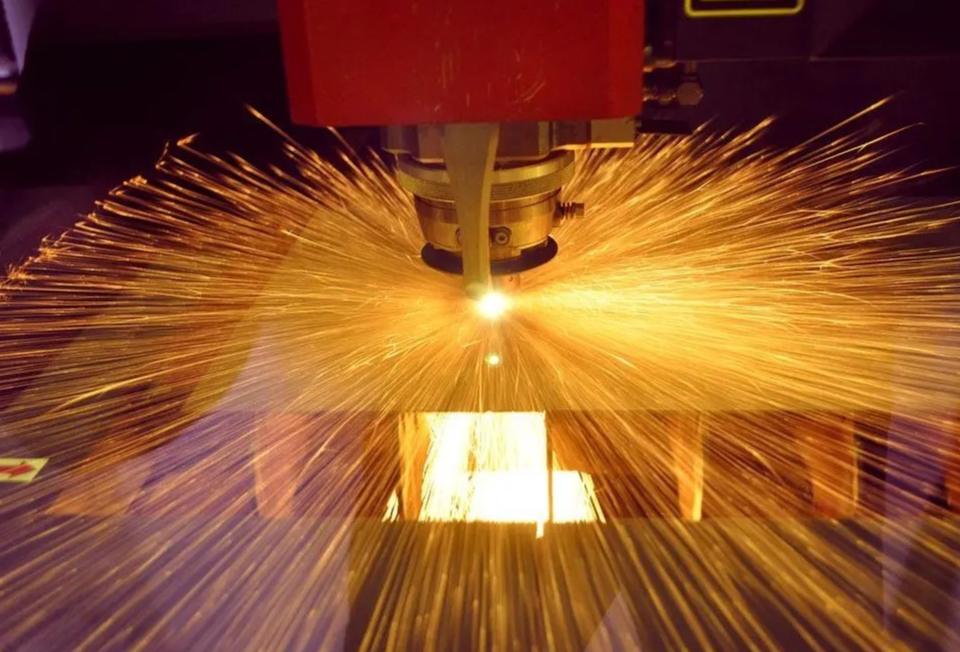

레이저 절단은 오랫동안 자동차 부품에서 항공 우주 부품에 이르기까지 산업 생산의 필수 요소로써 재료 처리가 정확하고 효율적으로 이루어졌습니다. 다양한 레이저 절단 기술 중, 섬유 레이저 절단은 뛰어난 장점으로 전통적인 CO2 레이저 절단을 빠르게 대체하고 있으며 정밀 가공 분야에서 게임 변경자로 부상하고 있습니다.

기존의 CO2 레이저 절단과 비교하면, 섬유 레이저 절단에는 뚜렷한 이점이 있습니다. 기술적으로, 이의 파장은 1064nm에 불과합니다. 이산화탄소 레이저의 10분의 1 정도입니다. 예를 들어, 저탄소 강철은 섬유 레이저 에너지의 35%를 흡수하고, CO2 레이저 에너지의 10%를 흡수합니다. 이것은 섬유 레이저가 알루미늄과 구리 같은 반사성이 높은 재료를 쉽게 잘라낼 수 있게 해줍니다. 우수한 빔 품질과 높은 절단 정확도로요.

효율 측면에서 파이버 레이저 절단은 기존 방식을 크게 앞선다. 얇은 스테인리스강 시트를 절단할 경우 CO₂ 레이저 절단보다 2배에서 3배 빠르다. 2kW의 파이버 레이저 절단 장비는 0.5mm 두께의 저탄소강을 분당 40미터 속도로 절단할 수 있다. 중간 두께의 재료의 경우 더 낮은 출력으로 동일한 절단 결과를 얻어 생산 효율을 크게 향상시킨다.

장비 자체도 기업들에게 매력적이다. 기존의 CO₂ 레이저 절단기는 크고 무거우며 빔 전달에 거울을 의존하기 때문에 대형 포맷 및 다차원 절단에 한계가 있다. 반면 파이버 레이저는 광섬유를 통해 에너지를 전달하므로 소형화된 설계로 공간을 절약할 수 있다. 임의의 형상, 파이프, 특수 프로파일까지 유연하게 절단이 가능하며 산업용 로봇과 결합하면 3D 절단이 가능해 다양한 복잡한 가공 요구 사항에 대응할 수 있다.

비용 장점이 인기를 더욱 높이는 요인으로 작용합니다. 파이버 레이저는 최대 30%에 이르는 전기-광학 변환 효율을 자랑하며, 이는 CO₂ 레이저보다 3배 이상 높아 전력 소비를 크게 줄입니다. 복잡한 광도파 시스템이 없기 때문에 외부 광학 경로는 무보수 설계이며, 평균 고장 간 시간(MTBF)은 10만 시간을 초과하고 소모품도 거의 필요하지 않습니다. 이는 기업의 운영 및 유지보수 비용 측면에서 상당한 장기적 절감 효과를 가져다줍니다.

오늘날, 섬유 레이저 절단 기술은 상당히 성숙해졌다. 연구자들은 두꺼운 판재 절단 품질 문제를 해결하기 위해 공정 매개변수를 최적화했으며, '스트리에이션 없는 절단'을 달성하여 표면 거칠기를 크게 줄였다. 정밀 가공 분야에서의 응용은 급속도로 확대되고 있으며, 의료 분야에서는 스테인리스강 혈관 스텐트를 제조하고, 0.02mm의 정밀도가 요구되는 정밀 기어를 생산하며, 항공우주 분야의 얇은 벽 부품에 대한 고정밀 요구 사항을 충족시키고 있다.

DMK는 항상 기술 트렌드의 선두에 서서, 제품 및 서비스에 광섬유 레이저 절단의 핵심 장점을 반영해 왔습니다. 효율적이고 정밀한 레이저 장비를 제공하든, 전문적인 가공 솔루션을 제공하든, DMK는 자체 기술 역량을 활용하여 다양한 산업 분야의 정밀 제조 능력을 향상시키는 데 기여하고 있습니다. 광섬유 레이저 절단의 실제 응용 사례를 탐색하거나 레이저 시스템과 관련된 요구 사항이 있으신 경우, 문의 메시지를 남겨 주시기 바랍니다. 함께 레이저 기술의 잠재력을 최대한 발휘해 봅시다!

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR