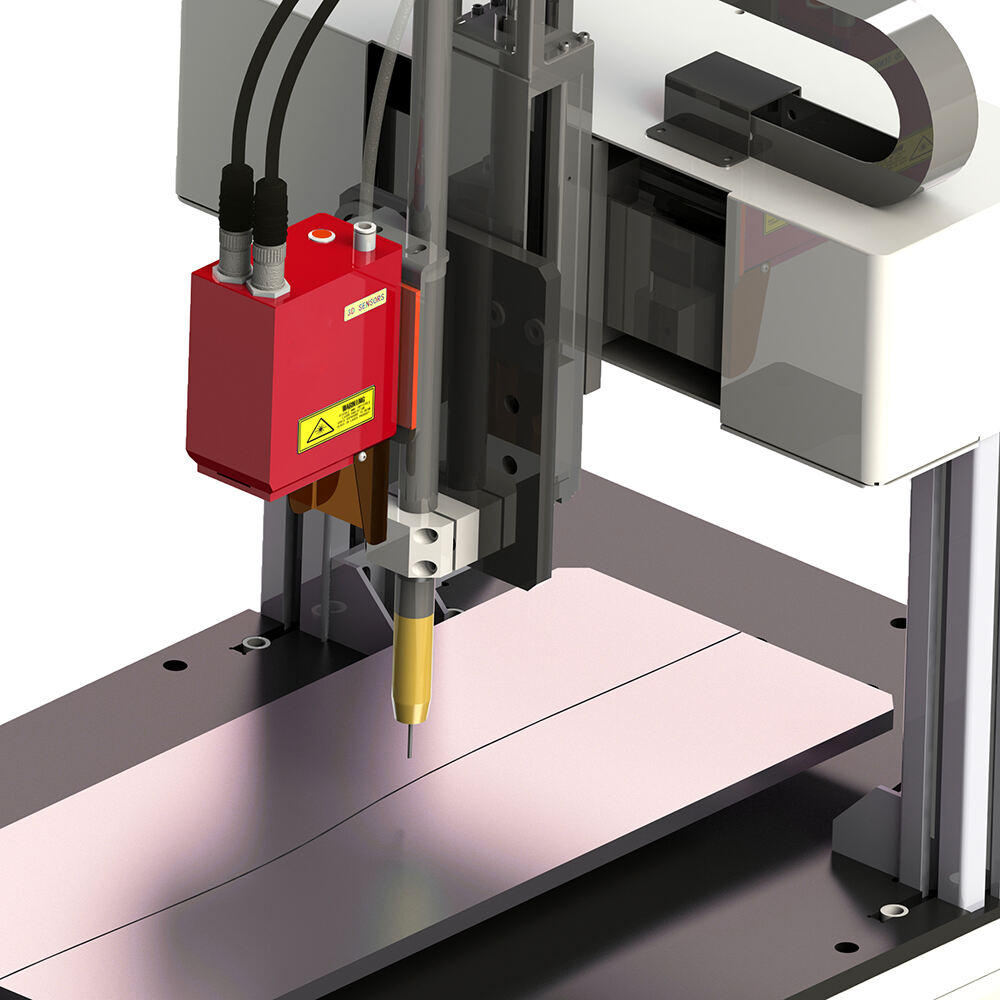

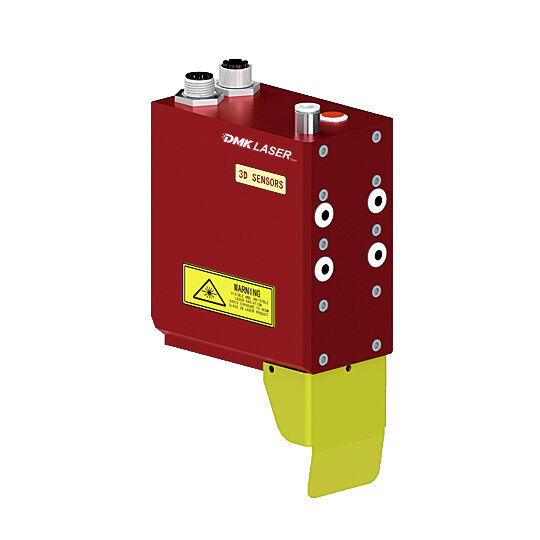

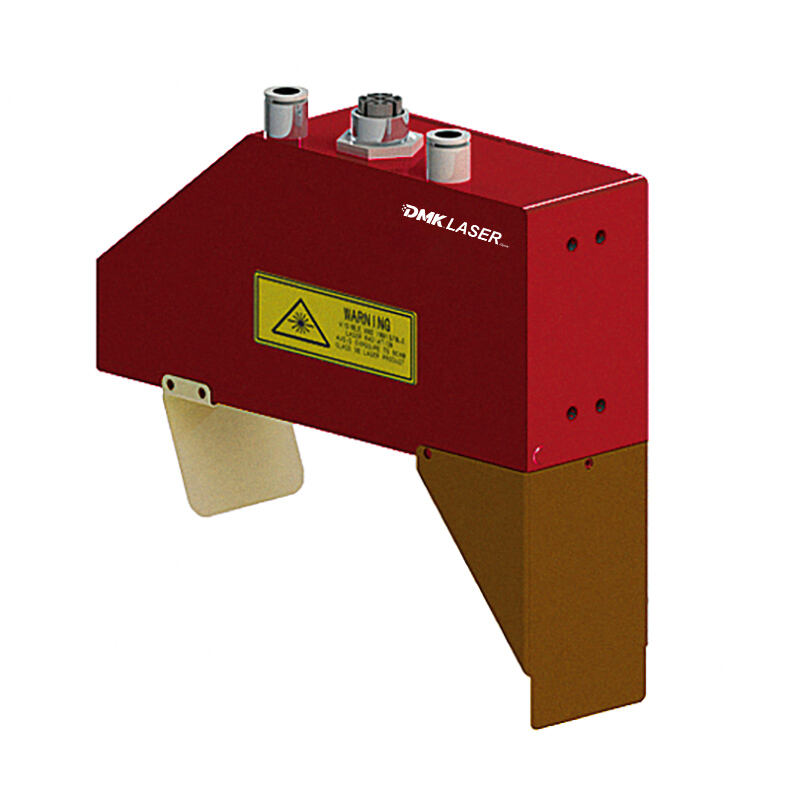

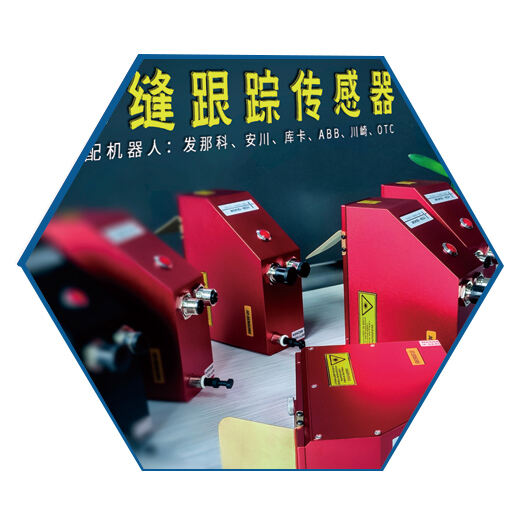

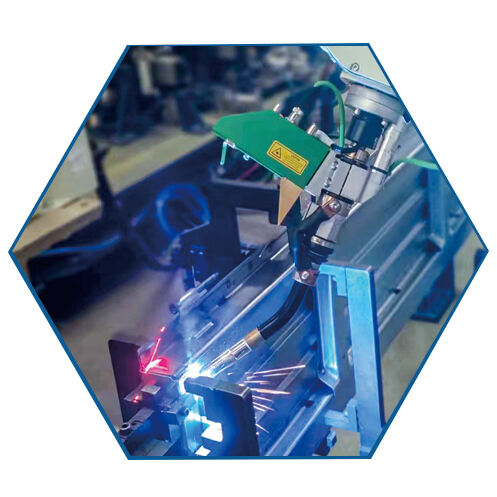

로봇 용접기용 DMK 3D 세임 트래킹 센서

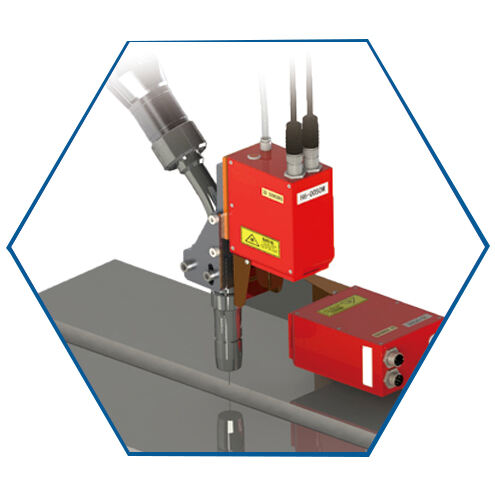

작동 원리

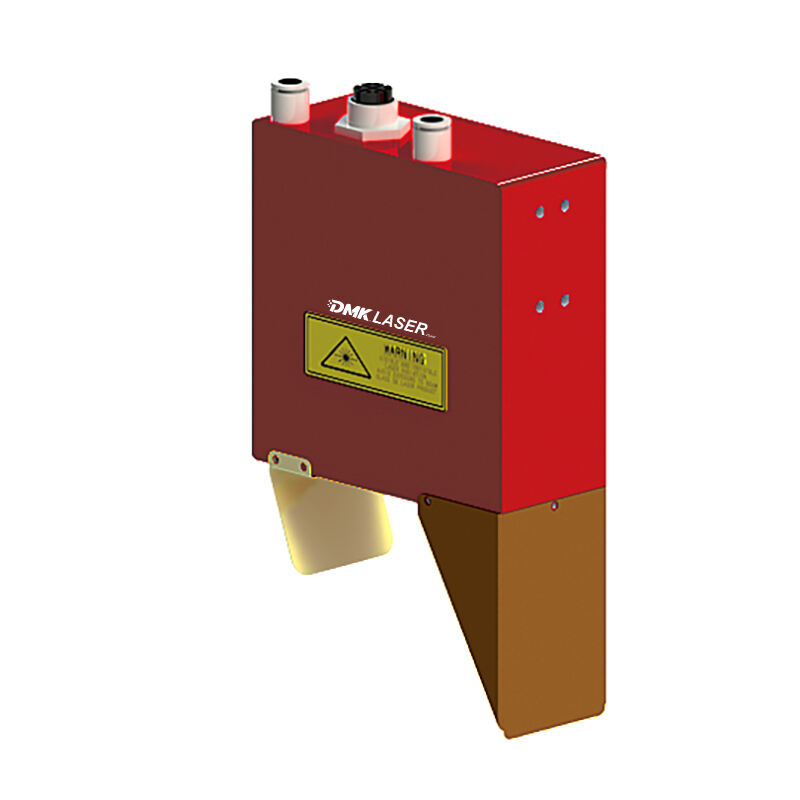

접합 추적 센서는 고급 레이저 삼각 측정 기술을 활용합니다. 레이저는 원통형 객체 렌즈를 통해 선형 레이저로 확산되어 대상 물체 표면에 투영되며, 확산 반사를 형성합니다. 반사된 빛은 이후 CMOS 카메라에 의해 포착됩니다. 반사된 빛의 위치와 형태 변화를 분석하여 센서는 변위와 표면 형태를 정확히 측정합니다.

제품 설명

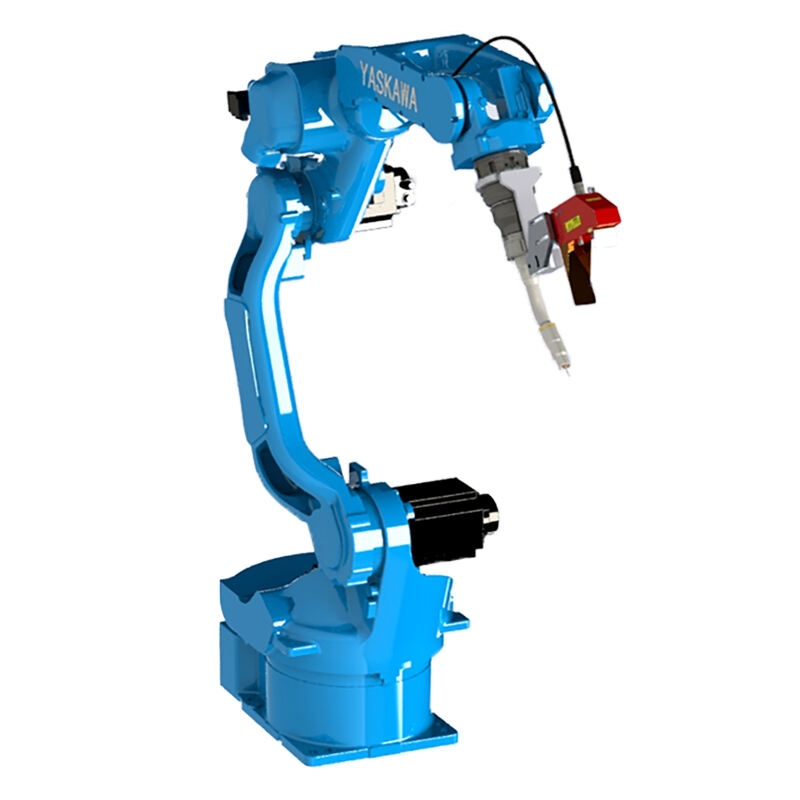

당사의 용접 이음매 추적 시스템은 최첨단 센서 기술과 정교한 알고리즘을 사용하여 용접 이음매를 고정밀로 실시간 추적합니다. 이를 통해 용접 편차를 최소화하여 용접의 정확도와 일관성을 크게 향상시킵니다.

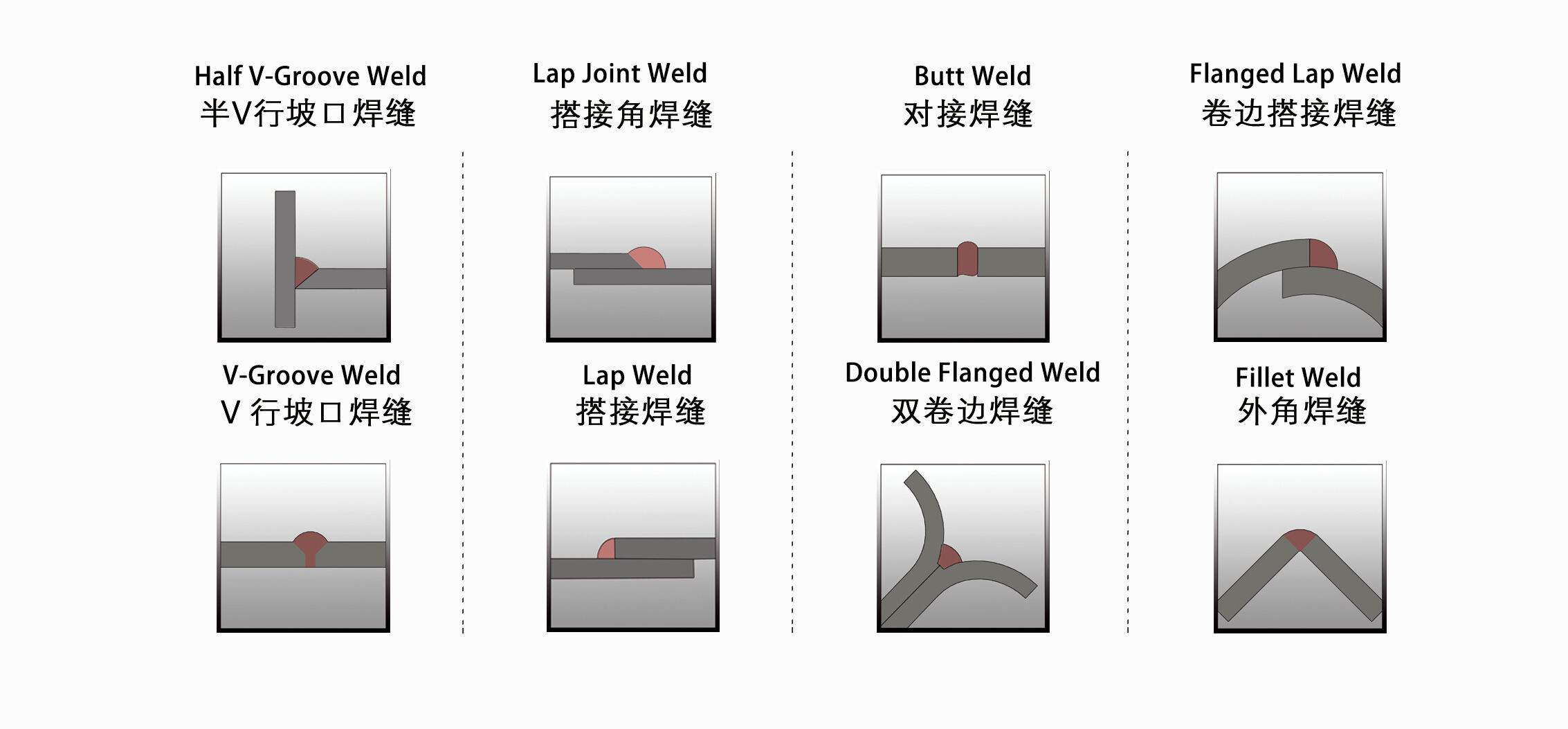

다양한 유형의 세임을 감지하고 추적할 수 있는 능력이 포함되며, 다음이 있습니다:

반 V 그루브 용접

버트 용접

오버랩 각도 용접

플랜지 오버랩 용접

V 그루브 용접

랩 용접

더블 플랜지 용접

외부 코너 용접

우리 시스템은 다양한 측정 시나리오를 처리하도록 설계되었으며, 0.011mm 해상도에서 1.758mm 측정 범위는 12mm에서 1100mm 로 대부분의 산업 응용 프로그램이 요구하는 정확도와 유연성을 제공합니다.

주요 특징

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

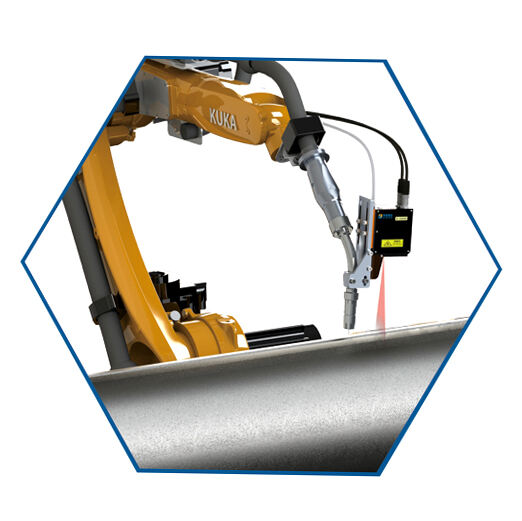

응용 분야

자동차 산업: 자동차 부품 용접에 대한 높은 정밀도를 보장합니다.

선박 건조: 정확한 seems 추적을 요구하는 대형 구조물 용접에 적합합니다.

중장비 제조: 산업용 기계의 용접 품질을 향상시킵니다.

항공우주: 항공 우주 부품에 대해 정확한 seems 추적을 보장합니다.

제작 및 맞춤 용접: 대규모 제작 프로젝트와 특수 용접 응용 분야에 완벽합니다.

교육 및 지원

우리의 seems 추적 센서를 구매할 때, 우리는 포괄적인 교육 서비스 , 포함 SDKs , 튜토리얼 비디오, 그리고 원격 기술 지원 무결점 통합 및 운영을 보장하기 위해 도움을 줍니다.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR