Collaborative Robot Laser Welding: A real ways that has been revolutionary weld materials.

Welding is a process of joining several content temperature that are making use of force, and/or the filler steel. It truly is found in different companies such as for instance construction, automotive, plus aerospace. DMK laser welding can be very a dangerous work, however the usage of collaborative robot laser welding has managed to ensure it is the safer and even more choice that was accurate.

This DMK Collaborative Robot Laser Welding has benefits which are numerous welding that is conventional. Among the importance that is greatest are protection. Given that the robot completes the procedure that is welding there is certainly less threat of damage for employees. And this also eliminates the necessity for heavy defensive gear which can add on to employee tiredness.

A benefit that is additional accuracy. Collaborative robots is programmed to follow precise welding patterns that guarantees welds which may be constant time. This improves the standard of the weld plus decrease the odds of mistakes plus rework. Furthermore, robots could even weld at the more quickly rate than people, that could spend less plus time.

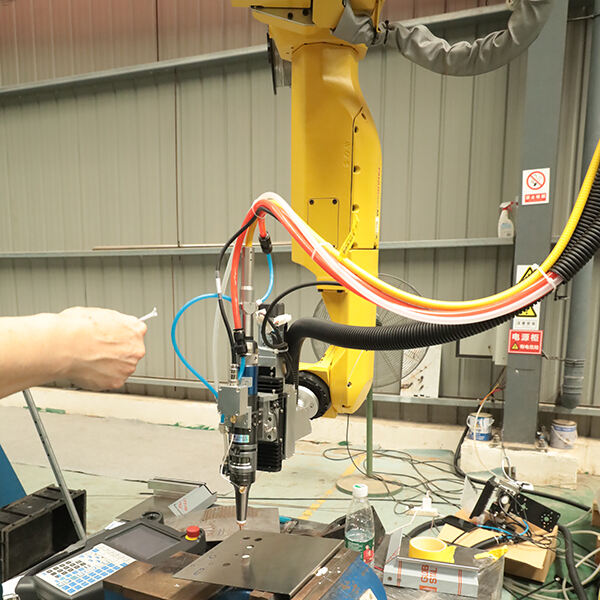

The application of collaborative robot laser welding machine is certainly a strategy that has been revolutionary welding enabling for substantially more freedom plus control. Collaborative robots of DMK are made to work alongside people, meaning they could be programmed to get leads to smaller areas that are sized with most components being intricate. This may make it better to weld components which are impossible as hard for individuals to get into.

Collaborative robot laser welding is really a safer choice than old-fashioned welding techniques. Collaborative robots is programmed to your office during the distance that are safer employees, that decreases the chance of damage. Furthermore, DMK collaborative robots laser welding equipment has sensors plus digital cameras which permit them to find out plus react to prospective issues in real-time. Meaning that in instances where an employee comes to the workplace, the robot shall stop till it really is safer to resume.

Collaborative robot laser welding is utilized in a variety of companies such as automotive, aerospace, and production. It's best suitable for welding content and that can be thin which causes that it is great for applications such as for instance human body panels plus fuel tanks. This DMK collaborative robot laser welding may also be used to weld content being various because aluminum plus metal.

We now have integrated the most laser that is present into our procedures. Working with the top American vendors of laser devices and control systems like Raycus, MAX, JPT, Friendess, Raytools, SUP, QILIN, and ESTUN we are committed to supply the markets with the more laser that are economical welding, cleaning, cladding, and marking equipment. We very carefully select the elements we use for our laser equipment. We additionally control assembly processes and perform Collaborative Robot Laser Welding which are thorough. We assist Chinese manufacturers to provide better lives for global people with our efforts.

DMK is situated inside the East Lake High-tech Development Zone (Optics Valley) in Wuhan, China. Our company is the company which try high-tech specializes in developing, research, manufacturing and distribution of complete laser equipment. The creator's group was comprised of postgraduate degree holders and we now have an organization comprised of greater than a dozen researchers which can be technical. With the manufacturing center that is current for laser equipment, in addition to a comprehensive after-sales team that may provide custom solutions for laser processing equipment that try automated to worldwide and domestic customers. We also offer professional after-sales support to help users resolve any pressing dilemmas with their products or Collaborative Robot Laser Welding.

Presently, our company has generated a supply chain which covers eight biggest areas and lots of products that add complete machine production of laser machines that is cutting laser machines which is welding cleansing machines and the supply of elements fiber which are including cutting minds for lasers, laser welding minds since laser cleaning head and laser control systems. Our products are commonly used in industries such as for instance for example sheet metal processing and protection that are {keyword} which is agricultural shipbuilding, aerospace, and energy that will be additionally new. The Middle East, Western Europe, and Russia with the capability to export and import goods minus restriction our merchandise have won more market share in international areas like East Asia, North America, Latin America.

We constantly adhere to the core values of "customer-centricity" and "creating customer-satisfying benefits." We give consideration to consumer specifications towards the top of your number of priorities. We actively take part in the "Made in China 2025 initiative" and use technologies and services to upgrade the laser industry intelligently. Inspiring by the two forces of Internet+ and Industry 4.0 and Industry 4.0, we closely proceed with the needs that is due to the Internet which was industrial age. We provide the important advanced level Collaborative Robot Laser Welding and application-related services in the business and collaborate with our supply chain to assist clients get faster, better, and additional growth which is effective.

The things become welded is first ready plus positioned to utilize collaborative robot laser welding. The robot laser welding machine shall be programmed aided by the welding that is true plus settings. After the robot try prepared, the welding procedure will start. The DMK robot can monitor the weld and work out changes as required throughout the procedure. After the welding was complete, the robot shall stop as well as the content may be eliminated.

The merchandise quality plus services of collaborative robot laser welding are essential factors when choosing this tech. It is important to decide on the company and expertise in collaborative robot welding reason that is sufficient the history of quality efforts. DMK services must also have the ability to provide help which are ongoing repair to guarantee the robots is running at their finest.

Collaborative robot laser welding coming from DMK may be used in a number of applications, like automotive human body panels, fuel tanks, plus equipment which are commercial. It is also found in the aerospace markets to weld aluminum structures. Collaborative robot laser welding may be a revolutionary plus safer solution to weld content, and its particular own utilize goes on in appeal.