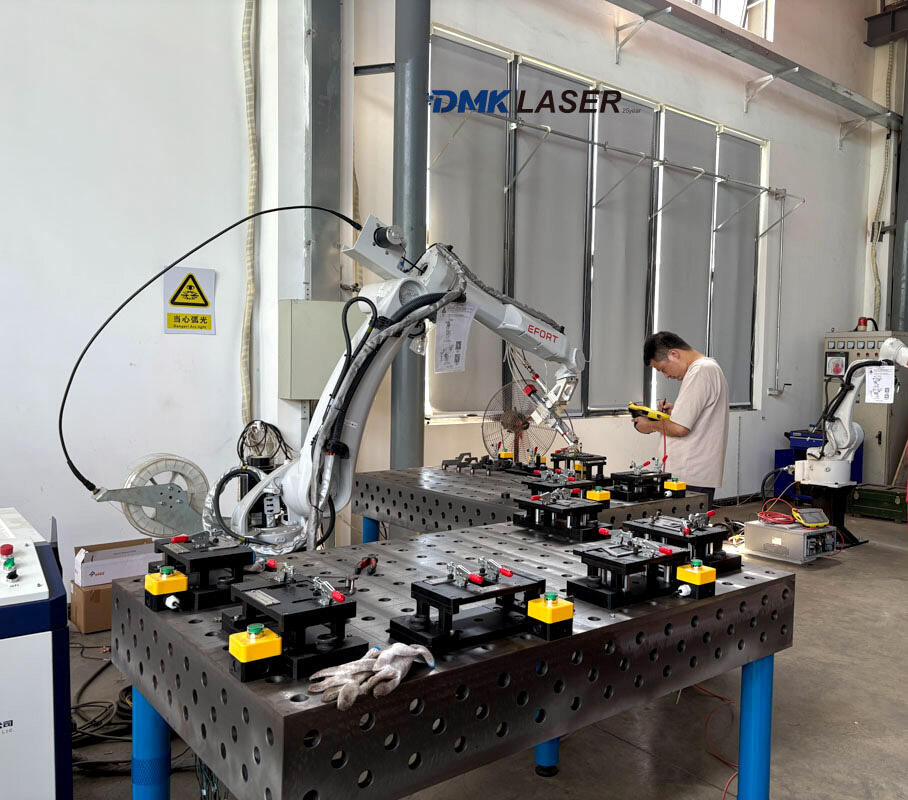

Inside Demark’s High-Capacity Manufacturing Powerhouse

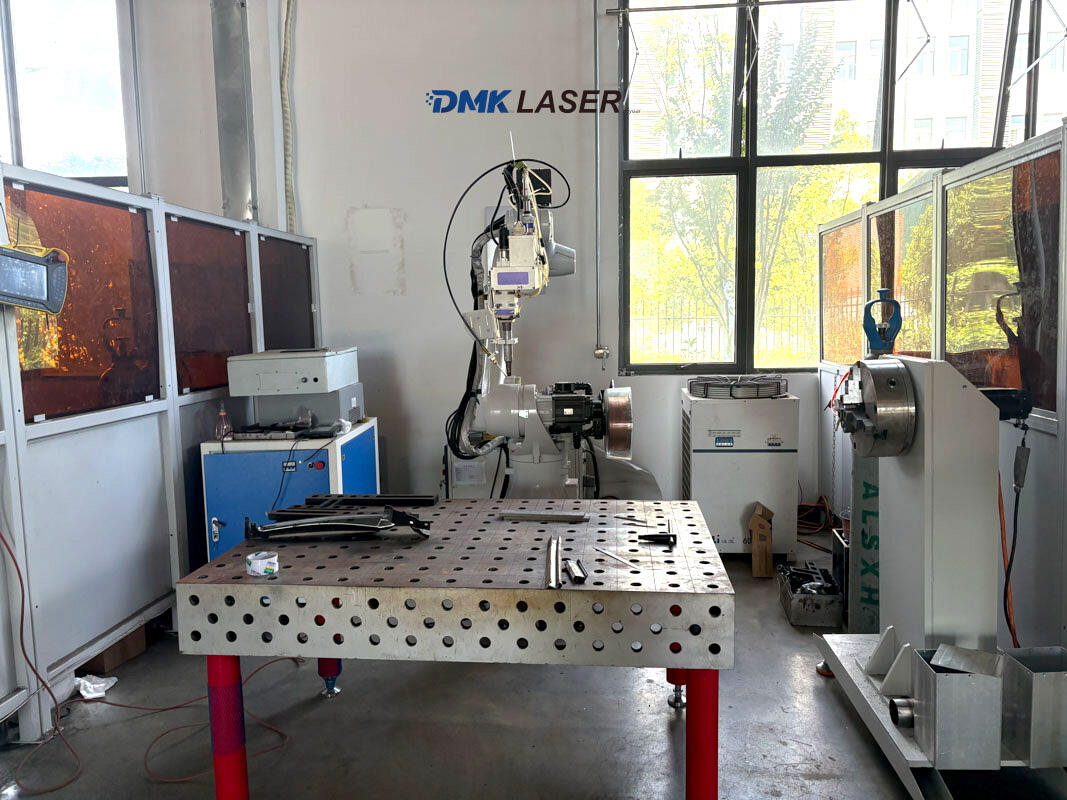

Demark’s factory is now operating at full capacity, producing large volumes of advanced robotic arms for applications such as automated welding, 3D cutting, and other precision tasks. These robotic arms are designed to help companies save labor costs, improve efficiency, and maintain consistent high-quality output.

Our strong production capability ensures we can fulfill both small and large orders quickly, while maintaining strict quality standards. Every robotic arm undergoes careful testing, and our use of high-grade materials and advanced motion control systems guarantees durability and precision.

Purchasing from Demark means more than just reliable equipment. We provide professional online after-sales support from a team of experienced technical experts who can guide customers through installation, operation, and troubleshooting. This ensures minimal downtime and smooth operation for all production lines.

With our robotic arms, manufacturers can streamline processes, boost productivity, and reduce operational costs. From automotive assembly to metal fabrication and 3D processing, Demark’s automation solutions are trusted by companies looking to enhance their manufacturing capabilities.

Demark combines advanced production capacity, high-quality equipment, and professional support to deliver robotic arms that meet the demands of modern manufacturing. For businesses seeking reliable automation solutions, Demark is ready to provide both the equipment and the expertise to help them succeed.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR