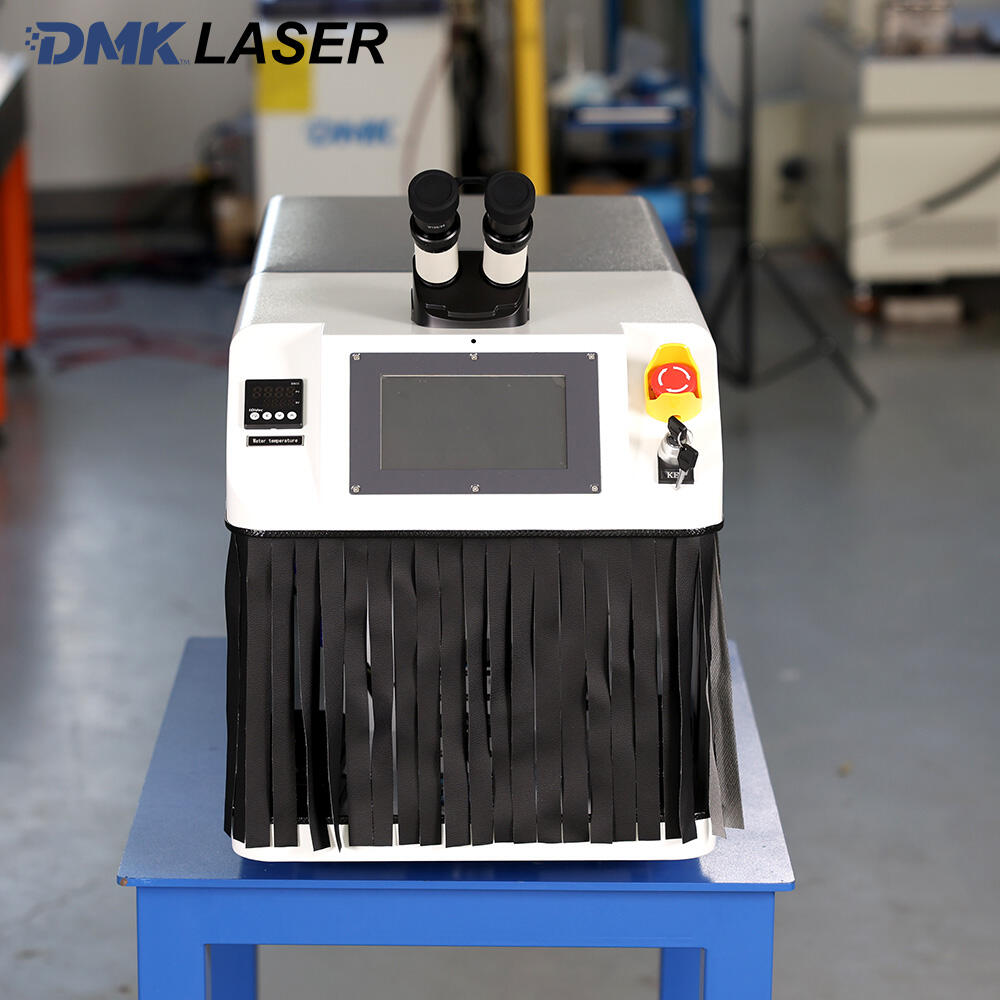

DMK 150W šperkovnický laserový bodovací svařovací stroj

Přehled produktu

Hledající profesionální šperkovnické svařovací řešení které kombinuje přesnost, rychlost a snadnost použití? HB-SW Series Laser Spot Welder je vaše nejlepší volba. Navržen pro šperkaře, opravny a malé výrobní podniky, tento stroj zajišťuje vysoce kvalitní svařování i na nejmenších komponentech bez poškození kamenů nebo jemných nastavení . Ideální pro zlato, stříbro, titan, platina a další!

Proč si vybrat HB-SW Laser Spot Welder?

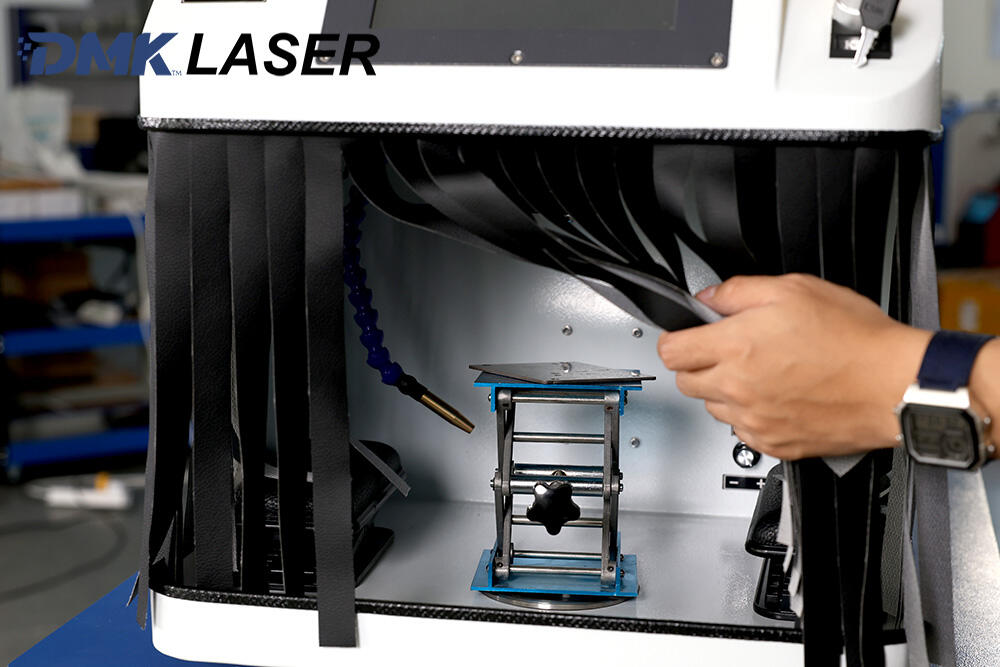

✔ Ideální pro šperky – snadno zpracujete zmenšování prstýnků, opravy náramků a jemné detaily.

✔ Bezpečné a spolehlivé – vestavěná automatická ochrana záření pro ochranu očí.

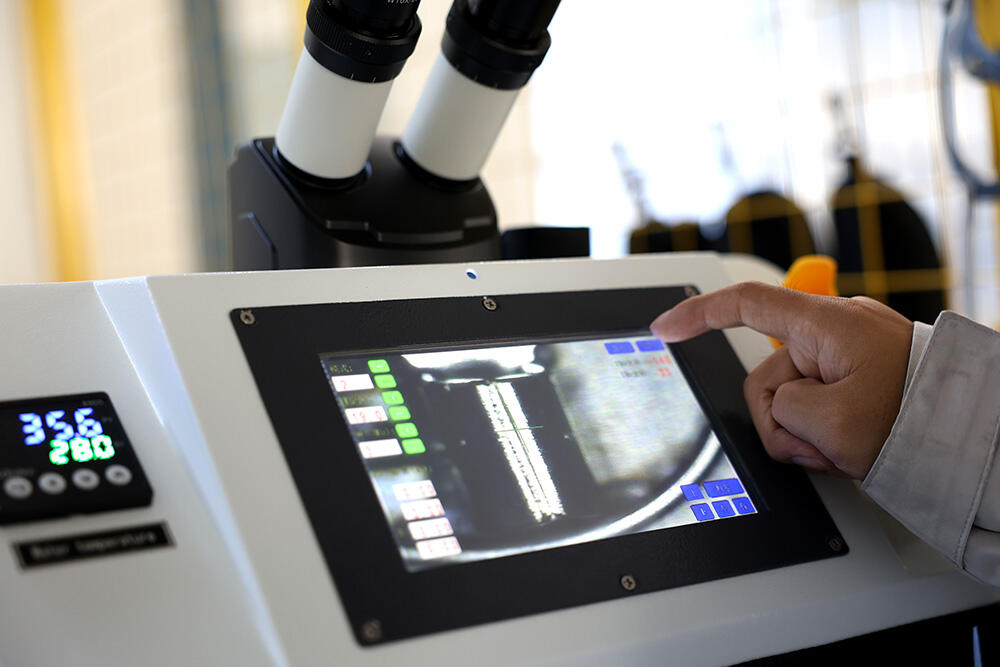

✔ Přesná kontrola – nastavujte šířku pulzu, frekvenci a energii pro bezchybné výsledky.

✔ Funguje s různými kovy – zlato, platina, titan, stříbro, měď, hliník a nerezová ocel.

✔ Trvanlivý výkon – nepřetržitý provoz 24 hodin s až 10 000 hodinami bezúdržbového provozu.

Hlavní vlastnosti

Nastavitelné svařovací parametry pro různorodé materiály a aplikace

Dovoz keramického reflektoru pro vysokou odolnost a optický výkon

Ergonomický design pro pohodlnou a neúnavnou práci

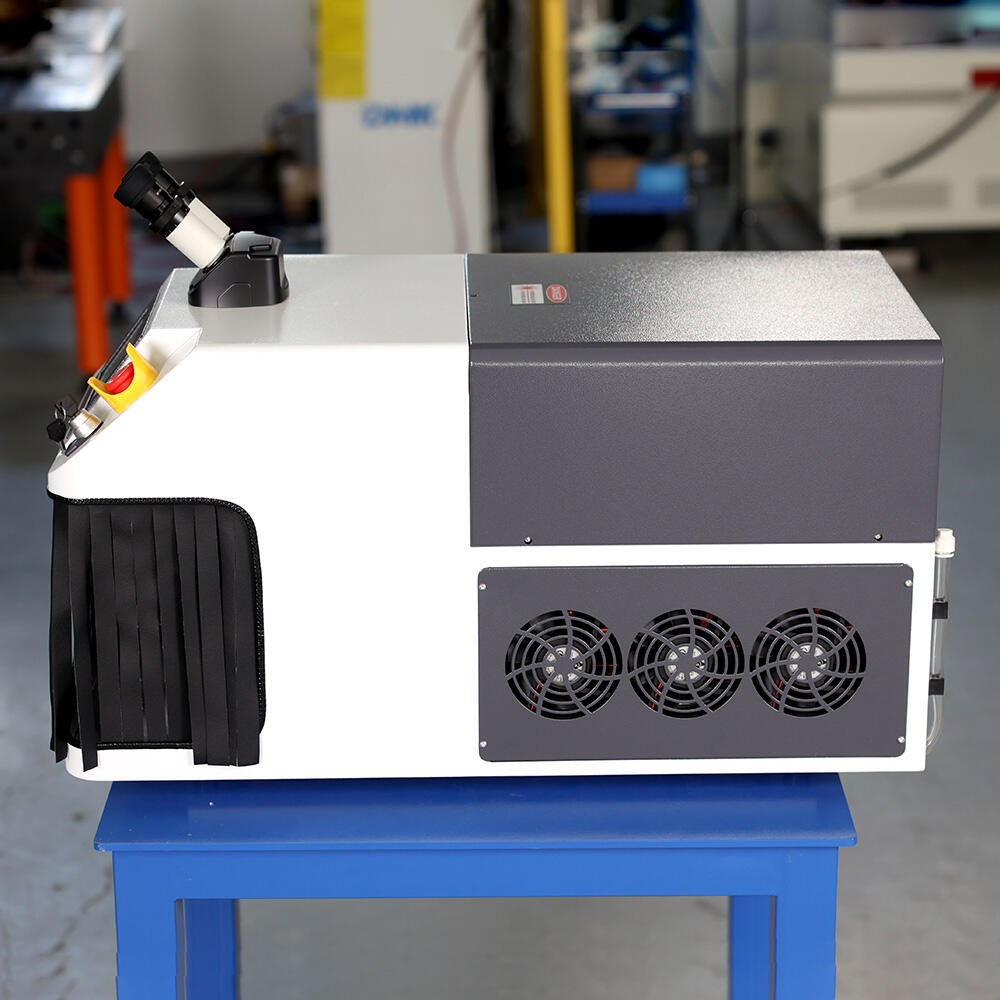

Kompaktní a profesionální konstrukce optimalizováno pro použití v dílně

|

|

|

|

Technické specifikace

| Laserový zdroj | Nd³:YAG |

| Vlnová délka | 1064 nm |

| Pulzní frekvence | Až 115 Hz (nastavitelné) |

| Šířka pulsu | 1,5 – 20 ms nastavitelné |

| Energie jednoho pulsu | 40 J |

| Jmenovitý výkon laseru | 150 W |

| Průměr soustředěného paprsku | 0,12 mm |

| Zvětšení mikroskopu | 10X |

| Ohnisková vzdálenost | 110 mm |

| Napájení | AC 220 V, jednofázový |

| Spotřeba energie | 3 KW |

| Prostředí | 5 °C – 30 °C, vlhkost < 85 % |

| Spojitý čas práce | 24 hodin |

| Připojení ochranného plynu | Argon, rychlorozpoj |

Použití

Činí ideální

Šperkařské dílny

Oprava brýlí

Zubní laboratoře (titanové protézy)

Elektronické součástky

Přesné svařování malých kovových dílů

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR